Dollar Tree Aluminum Foil Sheets for Construction Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

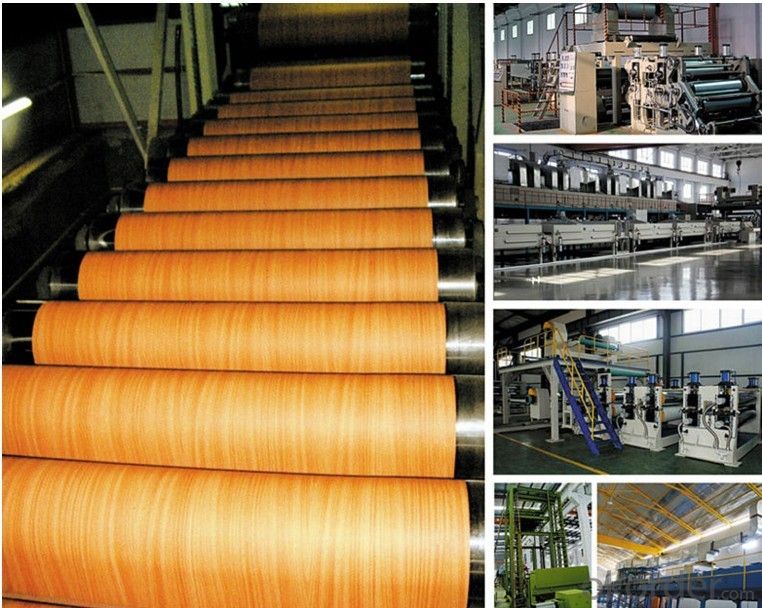

Structure of Aluminium Sheet for Construction Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Sheet for Construction Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Sheet for Construction Application:

Aluminium Sheet for Construction Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are aluminum sheets resistant to vibration?

- Yes, aluminum sheets are generally resistant to vibration. Aluminum is a lightweight and flexible material that has good damping properties, meaning it can absorb and dissipate vibrations. Additionally, aluminum has a high strength-to-weight ratio, which allows it to retain its structural integrity even when subjected to vibrations. This makes aluminum sheets a popular choice in industries such as aerospace, automotive, and construction, where vibration resistance is important. However, it is worth noting that the specific resistance to vibration may vary depending on factors such as the thickness and alloy of the aluminum sheet, as well as the intensity and frequency of the vibrations.

- Q: What is the coefficient of friction for aluminum sheets?

- The coefficient of friction for aluminum sheets can vary depending on the specific conditions and surfaces involved.

- Q: What is the maximum temperature that aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can withstand depends on several factors such as the alloy composition, thickness, and intended application. Generally, aluminum has a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit). However, aluminum sheets can typically withstand much higher temperatures without melting or deforming. For most commercially available aluminum alloys, the maximum temperature for continuous use ranges from 200-300 degrees Celsius (390-570 degrees Fahrenheit). Beyond this range, the material may start to experience reduced strength and increased susceptibility to deformation or damage. However, it is important to note that the specific maximum temperature limit for a particular aluminum sheet should be determined by consulting the manufacturer's specifications or conducting specific testing. Factors such as the presence of coatings or surface treatments, exposure to heat for extended periods, and thermal cycling can also affect the maximum temperature tolerance of aluminum sheets.

- Q: Can aluminum sheets be used for balcony railings?

- Indeed, balcony railings can be constructed using aluminum sheets. Aluminum is widely favored for balcony railings because of its lightweight properties, durability, and resistance to corrosion. This adaptable material can be effortlessly molded into various shapes and designs, making it suitable for a range of architectural styles. Moreover, aluminum railings necessitate minimal upkeep and can endure inclement weather conditions, rendering them an astute and enduring selection for balcony railings.

- Q: Are 101 aluminum sheets readily available in the market?

- Indeed, the market offers a wide range of readily available 101 aluminum sheets. Owing to their exceptional resistance to corrosion, impressive strength, and lightweight nature, these sheets find frequent use across various industries and applications. They can be conveniently obtained from metal supply stores, online marketplaces, and specialized aluminum suppliers. Moreover, customers have the liberty to select from a variety of sizes, thicknesses, and finishes for 101 aluminum sheets, ensuring the perfect match for their specific needs.

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation. Aluminum has good soundproofing properties due to its high density and ability to reflect sound waves. When used as a barrier or in combination with other sound-absorbing materials, aluminum sheets can effectively reduce noise transmission.

- Q: This question asks for a comparison of aluminum sheets with other materials regarding their cost and performance.

- <p>Aluminum sheets are generally cost-effective and offer excellent performance compared to many other materials. They are lightweight, which reduces material and transportation costs. They also have high strength-to-weight ratios, making them durable and resistant to corrosion. In terms of performance, aluminum sheets are versatile, used in various industries such as construction, automotive, and aerospace. They conduct heat and electricity well, which is beneficial for applications requiring thermal or electrical conductivity. However, they may be more expensive than some plastics or cheaper metals like steel on a per-unit basis, but their lower weight and durability often offset this cost over time.</p>

- Q: A solid aluminum sphere has a mass of 83 g.Use the density of aluminum to find the radius of the sphere in inchesExpress your answer using two significant figures.I can't figure this out :(

- Aluminum's density is about 2.7 grams per cubic centimeter. So a sphere with a mass of 84grams has a volume of about 31.111 cubic centimeters. You get this by dividing 84 by 2.7. Now that you know the volume, you can calculate the radius of the sphere. for a sphere, volume = 4/3 pi * radius to the third power. So 31.111 = 4/3 * (3.14...) * r^3. Divide both sides by 4/3 then divide both sides by pi and you get something like r^3 is 7.427. Then find the cube root of this to find your radius. I don't have a calculator, so someone should check the numbers.

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets are known for their excellent weather resistance properties. Due to their inherent corrosion resistance, aluminum sheets can withstand exposure to various weather conditions without deteriorating or rusting, making them highly suitable for outdoor applications. The protective oxide layer that naturally forms on the surface of aluminum provides a barrier against moisture, preventing the metal from reacting with oxygen and thus reducing the risk of corrosion. Additionally, aluminum sheets have high resistance to UV radiation, making them resistant to fading or discoloration caused by prolonged exposure to the sun. Overall, aluminum sheets offer exceptional performance in terms of weather resistance, making them a reliable choice for a wide range of outdoor applications, including roofing, siding, and outdoor signage.

- Q: What is the fatigue strength of aluminum sheets?

- The fatigue strength of aluminum sheets can vary based on several factors, including the composition of the alloy, thickness, condition of the surface, and the specific loading conditions. When compared to other metals, aluminum alloys typically exhibit favorable fatigue strength. To determine the fatigue strength of aluminum sheets, fatigue testing is commonly employed. This involves subjecting specimens to cyclic loading until failure. The fatigue behavior of aluminum sheets is characterized by the S-N curve, which represents the relationship between the applied stress amplitude (S) and the number of cycles to failure (N). Aluminum alloys, such as 2024-T3 and 6061-T6, are frequently used in industries like aerospace and automotive due to their high fatigue strengths. These alloys can endure millions of cycles at specific stress levels. For instance, at 10^6 cycles, 2024-T3 aluminum alloy has a fatigue strength of approximately 105 MPa (15,000 psi), while 6061-T6 aluminum alloy has a fatigue strength of around 96 MPa (14,000 psi). It is worth noting that the fatigue strength of aluminum sheets can be influenced by various factors, including surface defects, corrosion, temperature, and loading frequency. To enhance the fatigue strength, it is important to properly prepare the surface by smoothing it and eliminating sharp edges. Additionally, the use of appropriate stress relief treatments and design considerations, such as avoiding stress concentrations and optimizing joint design, can also improve the fatigue performance of aluminum sheets. In conclusion, the fatigue strength of aluminum sheets is generally considered good. However, it is crucial to consider the specific alloy, thickness, surface condition, and loading conditions in order to accurately determine and optimize the fatigue performance in practical applications.

Send your message to us

Dollar Tree Aluminum Foil Sheets for Construction Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords