DN125 Double Wall Concrete Delivery Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DN125 Double Wall Concrete Delivery Pipe

1. Structure of DN125 Double Wall Concrete Delivery Pipe:

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of DN125 Double Wall Concrete Delivery Pipe:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

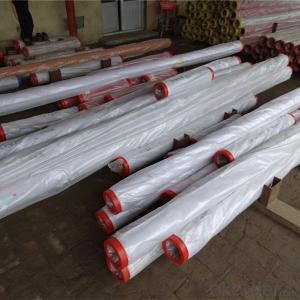

3. DN125 Double Wall Concrete Delivery Pipe Images:

4. DN125 Double Wall Concrete Delivery Pipe Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

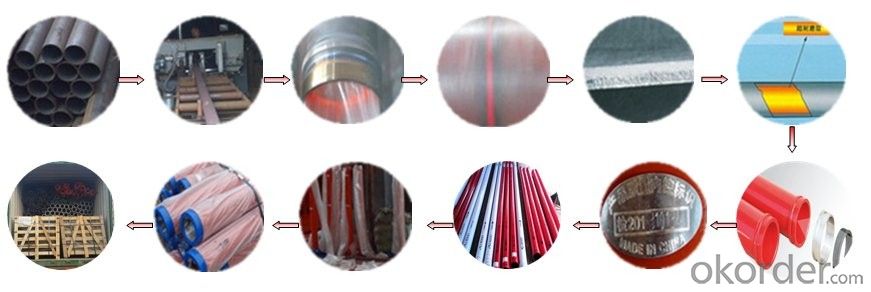

Production Process

5. FAQ:

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us:

• We are a comprehensive manufacturing and trading company.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: In the design of large machinery, it is to design the parts first, the assembly drawings as well

- This is the principle of the overall design process must go through to all aspects of the details, then how do you draw can use computer aided design. Now more flexible. If according to the traditional design from the general to the sub structure, clear whatever you draw.

- Q: Who knows what the design criteria for machine parts are, and how they are designed?

- 5. life standards, in order to ensure that the machine in a certain life span of normal work, in the design of mechanical parts, it is necessary to request the life of mechanical parts. It should be explained that parts can be replaced during the life of the machine, that is, the life of some mechanical parts is shorter than the life of the machine. The life of mechanical parts is mainly affected by fatigue, wear and corrosion of materials. In order to avoid failure caused by parts fatigue, such as fatigue fracture, fatigue strength should be calculated according to the fatigue limit corresponding to the life of mechanical parts. That is to say, according to the requirements of life and the specific speed of parts, according to formula (3-6), the fatigue limit is calculated when the stress cycle number is N. Then the strength condition is calculated and the fatigue strength is calculated. When the fatigue strength is satisfied, the stress cycle times of the mechanical parts can be guaranteed before the damage. Wear is usually unavoidable. Under certain conditions, corrosion is inevitable, such as structural members of bridges, corrosion of buried steel pipelines, etc.. In the design, mainly to ensure the mechanical parts in life, not excessive wear and corrosion. The mechanism of wear is still fully mastered, and there are many factors affecting wear. Generally, the wear resistance of friction pairs is improved according to the tribological design principle. The main measures are as follows: reasonable selection of friction pairs, reasonable choice of lubricant and additives, and control of the working conditions of friction pairs, such as pressure, sliding speed and temperature rise. So far, there is no practical and effective method for calculating corrosion life

- Q: What is the significance of using this "three changes" in mechanical design?

- Serialization refers to the same product, under the same basic structure or basic conditions, set out a number of different size seriesGeneralization refers to the parts and components of the same structure and size, which are used in different kinds of products or different specifications of similar products"Article three" the main benefits are: to reduce the design workload, improve design quality and shorten the production cycle; reducing tool and gauge specifications, easy to design and manufacture, thereby reducing the cost; for the organization of standard parts of the scale, specialization, to ensure product quality, material saving, cost reduction; improve interchangeability, easy maintenance; macro management and regulation for the country and in foreign trade; to facilitate evaluation of the quality of products, to solve the economic disputes.

- Q: In mechanical design, what is the significance of drawing 3D drawings?.

- Advantages: first, look at the intuitive ah, design some complex parts and components, do not express several views.After assembly, the parts can be checked for size. And whether or not to interfere.Three, the software has powerful functions, such as calculation of volume, weight, force analysis and so on, these are two-dimensional software can not compare.

- Q: Why do the design of mechanical parts (flanges and elbows) be based on the yield limit?

- In order to reach the yield limit, it is the failure of the material to begin the elasticity, and the elastic-plastic stage has been started. This is designed according to GB150-1998. You can look at the analysis data of the blasting process of the steel

- Q: How to write the machining process design of machine parts?

- According to each process that the part needs to be processed, the processing technique is determined.

- Q: I would like to open a small mechanical design company (specializing in the design of mechanical parts, etc.) can you make money?

- Now the society is not lack of talent, do what you want to find someone to test, the key is you have no contacts, there is no fixed customers, the company has its own R & D, and you have a big competitor is a variety of Design Institute, they have the strength, but also all kinds of qualifications, you must what do you want a good advantage. My point of view, there are fixed customers must make money, there is no fixed customers must lose money. I can try to get a mechanical design team on a team test.

- Q: Mechanical design practice course, let students do something

- The school is a rational knowledge, but the actual application is perceptual knowledge, the two change requires a process to know from the use,

- Q: What software is best for designing mechanical parts?

- The original is using autoCAD, and now popular with SOILDWORKS three-dimensional software, intuitive, easy to use, but also CAD function

- Q: University contact with some simple PLC, ladder diagram, but also to understand.I University of mechanical manufacturing, graduate students made a machine tool parts, mechanical design, University contact with some simple PLC, ladder diagram, but also to understand. Now work in contact with CNC machine tools, want to learn some numerical control system, electrical knowledge, to the job after adding some capital. Online to find some 840D information, that means too hard to see, what NCU, PCU, wiring, address completely do not understand. How do I study?

- NC, with FANUC, specific also don't understand. PLC, there are many brands, there are Ashkenazi SIEMENS, legal genealogy, Schneider, Japanese MITSUBISHI, OMRON, etc., Taiwan Delta, Yong Hong and so on other brands.

Send your message to us

DN125 Double Wall Concrete Delivery Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords