Mobile Concrete Hollow Core Roof Production Line

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Mobile Concrete Hollow Core Roof Production Line

1. Structure of Automatic Mobile Concrete Hollow Core Roof Production Line:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Automatic Mobile Concrete Hollow Core Roof Production Line:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

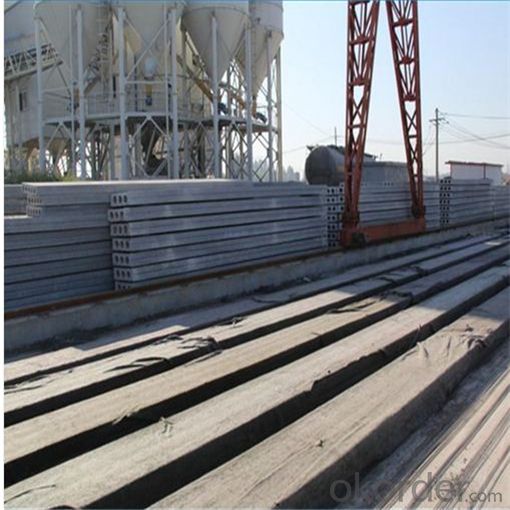

3. Automatic Mobile Concrete Hollow Core Roof Production Line Images:

4. Automatic Mobile Concrete Hollow Core Roof Production Line Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: is it the first overall drawing, or first out parts drawings, and then assembly?

- Personal habits ~ ~ general circumstances, the first overall map, and then parts map ~!

- Q: Who knows what the design criteria for machine parts are, and how they are designed?

- 5. life standards, in order to ensure that the machine in a certain life span of normal work, in the design of mechanical parts, it is necessary to request the life of mechanical parts. It should be explained that parts can be replaced during the life of the machine, that is, the life of some mechanical parts is shorter than the life of the machine. The life of mechanical parts is mainly affected by fatigue, wear and corrosion of materials. In order to avoid failure caused by parts fatigue, such as fatigue fracture, fatigue strength should be calculated according to the fatigue limit corresponding to the life of mechanical parts. That is to say, according to the requirements of life and the specific speed of parts, according to formula (3-6), the fatigue limit is calculated when the stress cycle number is N. Then the strength condition is calculated and the fatigue strength is calculated. When the fatigue strength is satisfied, the stress cycle times of the mechanical parts can be guaranteed before the damage. Wear is usually unavoidable. Under certain conditions, corrosion is inevitable, such as structural members of bridges, corrosion of buried steel pipelines, etc.. In the design, mainly to ensure the mechanical parts in life, not excessive wear and corrosion. The mechanism of wear is still fully mastered, and there are many factors affecting wear. Generally, the wear resistance of friction pairs is improved according to the tribological design principle. The main measures are as follows: reasonable selection of friction pairs, reasonable choice of lubricant and additives, and control of the working conditions of friction pairs, such as pressure, sliding speed and temperature rise. So far, there is no practical and effective method for calculating corrosion life

- Q: What are the basic criteria for the design of mechanical parts?

- 2. reliable and effective safety protectionAny job of dismantling an old machine is in such a danger that the risk of environmental conditions and the performance of the operator in a dynamic combination is greater when it comes to dismantling the parts of an old machine. As long as there is danger, even if the operator has good technical training and safety education, there are perfect procedures, but also can not completely avoid the risk of mechanical injury accidents. Therefore, a reliable material barrier must be established, that is, to install one or more protective devices, safety devices or other safety measures that are specifically designed to protect the safety of persons. When the equipment or operation of some aspects of the problem, relying on the mechanical safety of their own technical measures to avoid accidents, and ensure the safety of personnel and equipment. Equipment with high risk or high accident rate must be equipped with safety protection device.

- Q: What are the key factors in designing mechanical parts?

- 2- rationality. Also to the shaft, for example, the outer diameter tolerance depends on what things, such as with bearings, it must be in accordance with the requirements of the base hole design, that is, in accordance with the diameter tolerance of bearings to determine the diameter tolerance.

- Q: In the design of machine parts, how to choose the matching of bearings, what should be paid attention to when assembling?

- Bearings are purchased parts, shaft and bearing inner ring with the base hole selection, as for the flexibility of the match, depending on the use of requirements, assembly, of course, is to be installed smoothly. The bearing outer ring is matched with the box body, and the base shaft system is matched

- Q: How does the Auto CAD menu bar do not have the "mechanical parts design" command?

- Install or load other tools without having them

- Q: In mechanical design, what is the significance of drawing 3D drawings?.

- For professionals, 3D map painting aims at first can visually see the three-dimensional geometry of parts, followed by analysis of the existence of the assembly interference, meets the design goal and the size, volume, stress analysis.For non professionals, they do not understand the specialized two-dimensional graph, and can help them understand the geometry of the object by means of the three-dimensional graph.

- Q: I would like to open a small mechanical design company (specializing in the design of mechanical parts, etc.) can you make money?

- Really, the scope of the company's experience is not the design parts ah, better product design! Do you mean the standard parts? There are regular standard parts factory, if it is an industrial design company, that includes product appearance and internal structure design, it can not just design machinery products.If in Beijing, the best fixed source of the project, otherwise it is difficult to survive, the small Beijing design companies have as many as ten, the most famous is "Rococo" design, development of other city is not clear, but the design development in the south is better, the project will also, in Shenzhen for the.

- Q: What is the design procedure of mechanical parts urgently ah?!

- 5. assembly and parts diagram design. According to the structure and size of parts assembly sketches to determine the complete assembly and parts diagram design. (according to the plan to determine the main dimensions, structure design, parts drawing, sorting out the map) four, as the case with technical documentation requirements, design and coding machine calculation manual, manual, standard parts list, purchased parts list, etc. in the conditions of acceptance in the design process, such as a link the problem is feasible or not, need to return to revise the previous design, until the problem is solved. Sometimes, for this reason, even the whole project has to be knocked over. Therefore, the mechanical design process is an iterative process. (standard and outsourcing parts arrangement, specification preparation, acceptance documents

- Q: Good mechanical design or good mechanical manufacturing?

- generally refers to some large machinery, such as CNC grinding tools and so on, need to do it yourself, go to practice;

Send your message to us

Mobile Concrete Hollow Core Roof Production Line

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords