Concrete Pump Delivery Pipe 3 M*DN125*4.5Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

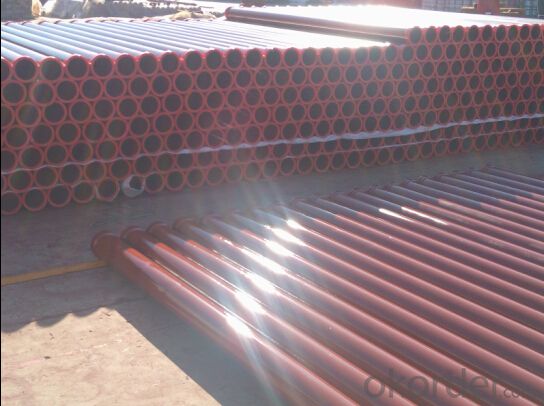

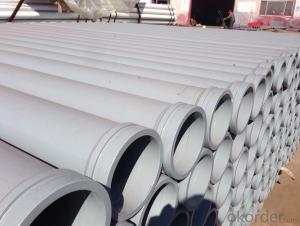

Production Name: Delivery pipe 3 M*DN125*4.5Thickness

Materials: ST 52

Concrete Pumping Capacity: about20, 000M3

Inner Diameter: 125mm

Outer Diameter: 133mm

Thickness: 4.5mm

Length: 3000mm

Notes: total series of concrete delivery pipe for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc)available.

Scope of Application of the Equipment

Delivery pipe 3 M*DN125*4.5Thickness widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc. Our concrete delivery pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber piston, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

Product Advantages:

Delivery pipe 3 M*DN125*4.5Thickness are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have their ISO certifications, and adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Delivery pipe 3 M*DN125*4.5Thickness according to customers request?

A4: Yes, we can produce Delivery pipe 3 M*DN125*4.5Thickness according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: How can one differentiate between genuine and counterfeit concrete pump spare parts?

- Differentiating between genuine and counterfeit concrete pump spare parts can pose a challenge, but there are several methods to ensure the authenticity of your purchase. Consider the following strategies: 1. Manufacturer Research: Begin by thoroughly researching the manufacturer of the concrete pump spare parts. Look for reputable, well-established companies with a proven track record. Analyze their industry standing, read customer reviews, and examine their website. Genuine manufacturers typically have a strong online presence and provide detailed product information. 2. Supplier Verification: When purchasing spare parts, it is crucial to select a reliable and authorized supplier. Ensure the supplier has a good reputation in the industry and a long-standing presence. Authorized distributors often have direct relationships with manufacturers and can provide authentic parts. 3. Inspection of Product Packaging: Genuine concrete pump spare parts typically have specific packaging that includes branding, logos, and detailed product information. Counterfeit products may have inferior packaging quality, misspellings, incorrect logos, or inconsistent color schemes. Carefully examine the packaging to determine its authenticity. 4. Evaluation of Product Quality and Finish: Counterfeit parts are often made from low-quality materials and lack the precision and finish of genuine parts. Inspect the spare parts for signs of poor workmanship, rough edges, or uneven surfaces. Genuine parts are typically well-crafted and undergo strict quality control measures. 5. Price Comparison: Exercise caution when encountering significantly lower prices for spare parts, as this may indicate counterfeit products. Counterfeiters often sell their goods at lower prices to attract customers, but the quality and performance may be compromised. Compare prices with other suppliers to ensure they fall within the expected range. 6. Seek Expert Advice: If you are unsure about the authenticity of concrete pump spare parts, consult industry experts or experienced professionals. They can assist you in identifying genuine components and making informed decisions. 7. Request Certifications and Documentation: Genuine manufacturers provide certifications and documentation, such as ISO certifications or test reports, to validate the quality and authenticity of their products. Ask the supplier for these documents and verify their legitimacy with the manufacturer if necessary. Remember, purchasing genuine concrete pump spare parts is crucial for the safety and efficiency of your equipment. By following these steps and exercising caution, you can minimize the risk of purchasing counterfeit components and ensure the longevity and reliable performance of your concrete pump.

- Q: Can concrete pump spare parts be heat-treated or hardened for increased durability?

- Concrete pump spare parts can undergo heat treatment or hardening to increase their durability. By subjecting the parts to controlled heating and cooling processes, their mechanical properties can be altered. This alteration significantly improves their hardness, strength, and wear resistance, thus enhancing their durability and ability to withstand harsh operating conditions. Various heat treatment methods, such as quenching and tempering, induction hardening, and case hardening, can be applied to different types of spare parts, including cylinders, pistons, wear plates, and delivery pipes. These processes contribute to the overall performance and lifespan of the spare parts, ensuring their ability to withstand the demanding nature of concrete pumping operations.

- Q: What are the different types of concrete pump hopper agitator blades?

- There are several different types of concrete pump hopper agitator blades that are used in the construction industry. These blades are designed to efficiently mix and agitate the concrete mixture in the hopper, ensuring a consistent and homogeneous mixture before it is pumped onto the project site. 1. Paddle Blades: Paddle blades are the most common type of agitator blades used in concrete pump hoppers. These blades have a flat, paddle-like design that helps to mix the concrete ingredients effectively. They are typically made of high-quality steel or hardened rubber for durability and optimal performance. 2. Helical Blades: Helical blades are spiral-shaped agitator blades that are designed to create a gentle, swirling motion within the hopper. This type of blade is particularly effective in preventing the formation of lumps and ensuring a smooth and well-mixed concrete mixture. 3. Ribbon Blades: Ribbon blades are thin, flat blades that resemble ribbons. They are typically placed vertically in the hopper and rotate along their axis to mix the concrete ingredients thoroughly. Ribbon blades are known for their ability to prevent clogging and improve the overall efficiency of concrete pumping. 4. Fan Blades: Fan blades have a unique fan-shaped design that helps to agitate the concrete mixture by creating a powerful airflow within the hopper. This type of blade is particularly effective in preventing the segregation of concrete ingredients and maintaining a consistent mixture. 5. Tine Blades: Tine blades feature multiple prongs or tines that extend outwards from a central hub. These blades create a more aggressive agitation action, making them suitable for mixing heavier concrete mixes or those that contain large aggregates. The choice of agitator blades depends on various factors, including the type of concrete being used, the desired consistency of the mixture, and the specific requirements of the construction project. It is essential to select the appropriate blade type and ensure regular maintenance to optimize the performance and lifespan of the concrete pump hopper agitator.

- Q: If the concrete pump valve jam how to judge and deal with?

- After checking the blocked section, remove the pipe and use high-pressure air blowing or heavy hammer or high pressure water to wash it. After thoroughly cleaning, connect the pipeline to pump the concrete work.

- Q: How often should concrete pump water pumps be inspected and replaced?

- The frequency of inspection and replacement for concrete pump water pumps depends on several factors including the workload, operating conditions, and maintenance practices. Generally, it is recommended to inspect the water pump at least once a month to ensure its proper functioning. During the inspection, it is important to check for any leaks, unusual noises, or signs of wear and tear. If any issues are identified, immediate action should be taken to resolve them, such as repairing or replacing damaged parts. As for replacement, it is difficult to provide an exact timeframe as it varies depending on the quality of the pump, the intensity of use, and the level of maintenance. However, a general guideline is to consider replacing the water pump every 1-2 years for heavy usage or every 3-5 years for moderate usage. Regular maintenance, such as cleaning and lubricating the pump, can extend its lifespan and minimize the need for frequent replacements. It is important to note that these recommendations are general guidelines and may vary depending on the specific manufacturer's instructions, industry standards, and local regulations. It is advisable to consult the manufacturer's guidelines and seek professional advice from experts in the field to determine the appropriate inspection and replacement schedule for concrete pump water pumps in your specific circumstances.

- Q: In general, how much concrete will be transported per hour for the concrete pump and the pump?

- Tank car replacement, reversing the car by about 5-8 minutes

- Q: How do I properly maintain and replace wear plates in concrete pump spare parts?

- Properly maintaining and replacing wear plates in concrete pump spare parts is crucial for the optimal performance and longevity of your equipment. Here are the steps you can follow to ensure that the wear plates are properly maintained and replaced: 1. Regular inspection: It is important to regularly inspect the wear plates in your concrete pump spare parts to identify any signs of wear or damage. Look for cracks, excessive wear, or any other visible signs of deterioration. 2. Cleaning: Before replacing the wear plates, make sure to clean the area around them thoroughly. Remove any debris, dirt, or hardened concrete that might be present. Use a pressure washer or a wire brush to clean the surface properly. 3. Measure wear plate thickness: Measure the thickness of the wear plates using a precision measuring tool. Compare the current thickness with the manufacturer's recommended specifications to determine if replacement is necessary. If the wear plates are below the recommended thickness, it is time to replace them. 4. Remove old wear plates: Carefully remove the old wear plates using appropriate tools. Take note of their positions and any alignment marks to ensure correct installation of the new plates. 5. Prepare new wear plates: Before installing the new wear plates, ensure that they are of the correct size and specifications for your concrete pump. Check for any defects or damage in the new plates before proceeding. 6. Apply lubrication: Apply a thin layer of lubricant or anti-seize compound on the mating surface of the new wear plates. This will help prevent corrosion and ease future replacement. 7. Install the new wear plates: Position the new wear plates in the correct location, aligning them with any reference marks or indicators. Secure them tightly using the appropriate bolts or fasteners, making sure not to overtighten. 8. Test and check alignment: Once the new wear plates are installed, perform a test run of the concrete pump to ensure that everything is functioning properly. Check for any leaks, unusual vibrations, or misalignments. If any issues are detected, address them promptly. 9. Maintain regular maintenance schedule: To prevent premature wear and damage to the wear plates, establish a regular maintenance schedule. This may include cleaning, lubricating, and inspecting the wear plates at specified intervals or after a certain number of hours of operation. By following these steps and maintaining a proactive approach to wear plate maintenance and replacement, you can ensure the smooth operation and prolonged lifespan of your concrete pump spare parts.

- Q: How does a concrete pump clamp work?

- A concrete pump clamp is an essential component of a concrete pump that is used to secure and hold the concrete delivery pipeline in place. It works by tightly gripping the pipeline to prevent any movement or leaks during the concrete pumping process. Typically, a concrete pump clamp consists of two main parts: the clamp body and the wedge. The clamp body is usually made of durable steel and has a curved shape that is designed to fit around the pipeline. It is equipped with bolts or knobs that can be tightened or loosened to secure the clamp onto the pipeline. The wedge, on the other hand, is a piece of metal that is inserted into the clamp body. It is responsible for exerting pressure onto the pipeline when the clamp is tightened. By turning the bolts or knobs, the wedge is pushed further into the clamp body, causing it to squeeze the pipeline tightly and create a firm grip. The tight grip created by the concrete pump clamp is crucial as it ensures that there are no leaks or disruptions in the concrete flow. It helps to maintain a consistent and steady flow of concrete from the pump to the desired location. Additionally, the clamp also provides stability to the pipeline, preventing it from moving or shifting during the pumping process. Overall, a concrete pump clamp plays a vital role in the efficient and safe operation of a concrete pump. It ensures that the concrete delivery pipeline remains securely in place, allowing for a smooth and uninterrupted concrete pumping process.

- Q: What is the second generation pumping technology of concrete pump?

- Concrete pump, S pipe distribution without PLC electrical components to participate in, the failure rate is lower, more reliable control, product life has greatly improved

- Q: How often should concrete pump remote control batteries be replaced?

- Concrete pump remote control batteries should be replaced as needed, typically when they no longer hold a charge or fail to power the remote control effectively. The frequency of replacement will depend on factors such as battery quality, usage, and maintenance.

Send your message to us

Concrete Pump Delivery Pipe 3 M*DN125*4.5Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches