Seamless Concrete Pipe for Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Seamless Concrete Pipe for Concrete Pump

1. Structure of Seamless Concrete Pipe for Concrete Pump:

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

2. Main Features of Seamless Concrete Pipe for Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

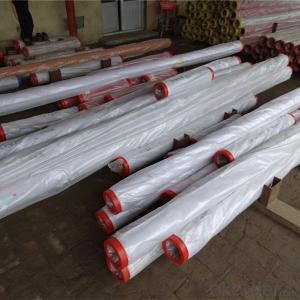

3. Seamless Concrete Pipe for Concrete Pump Images:

4. Seamless Concrete Pipe for Concrete Pump Specification:

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

Name | Data |

Material | 45MN2/20#/16MN/Q345 |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

Process | High temperature quenching |

HRC | 65 |

5. Why choose us:

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q:I am an ordinary graduate, two jobs to me, one is non-standard automatic design work, but the first half of the assembly in the workshop, and then to design. There is also a mechanical component CAD draftsman. After that, you can do part design. May I ask which job will have a future for you?

- How do you say, non standard salary is relatively high, but the difficulty is also great, what can relate to the requirements of the design experience, not newcomers can do. What about a draftsman? It's easy to get started after graduation, but it's easier to work long hours without a nonstandard design. Of course, but also depends on what specific units. Consider yourself. Hope to adopt

- Q:What are the main functions of CAE software commonly used in the design of mechanical products or parts?

- Strength, stiffness, modal analysis, structural optimization, and so on

- Q:In the design of large machinery, it is to design the parts first, the assembly drawings as well

- In the design of large machinery, it is to design the parts first, the assembly drawings as well

- Q:How to design the common mechanical parts with CATIA, and how to solve the problem when the units are inconsistent?

- Very simple. Write the value / conversion value of the drawing in the parameter

- Q:including design originality, manufacturing process, drawing, processing technology, cost calculation, and function

- Design ideas for mechanical parts? Never heard of it. I've only heard of mechanical creativity.

- Q:In the process of mechanical design, those areas should be designed as fillet and when to design chamfer. These materials can be found in those places, and the title of the book is also OK. Thank you!

- Fillet is generally cast out, chamfering is generally processed out.In order to eliminate stress concentration, a cylindrical part needs to be rounded in order to eliminate the stress concentration.In general, the outer circle, the inner hole and the threaded orifice need chamfering, some are the process requirements, some are assembly requirements (for example, you don't chamfer the parts, especially the smaller ones)...The old saying upstairs is what I want to say. I hit half and found it was called back

- Q:Why do the design of mechanical parts (flanges and elbows) be based on the yield limit?

- Hello friends, usually to do the experiment to the material ontology; have tensile, bending, impact, flattening, flaring, cyclamic, normal temperature test 20 degrees Celsius, is 20 degrees Celsius, minus 20 degrees Celsius, the test to the material, to be determined after completion of the test material meets the design requirements. Is the so-called (to yield limit for design basis?)

- Q:Does the SolidWorks mechanical design engineer paint parts individually or draw parts in an assembly?

- Either way, in actual work, the two approaches may alternate.If you do is mechanism design, may be other assembly references, can consider each part separately draw, so in the future by other assembly references when good maintenance, no loss of reference.If you do need to consider other parts of the related parts, such as the appearance of the skin, a variety of sports organizations, etc., can be considered to create parts in the assembly, can avoid some mistakes when combined with other parts. However, it is still recommended that you minimize the external reference in the assembly and make the key features that require external reference, and that the rest of the features are still done in an independent part manner.

- Q:I am a bachelor degree in industrial design and have been sitting here for two months now, 20The feeling is still not understand, not figure painting, other colleagues are busy, I could not ask, do not know how to do, give me a leading figure today, let me figure it out on my own, I draw more and more have no confidence, I do not know because many mechanical components, do not know how to do.. Tired ~ ~ mechanical aspects of the great God, I pointed to the Ming road! Thanks

- A mechanical design is learning by doing, the school learned to pick it up, in addition to learn how to use the design manual, design experience for reference to others

- Q:In mechanical design, what is the significance of drawing 3D drawings?.

- Product design is to determine the shape of the product and product function, but also the decisionThe most important part of the product quality, the product design work on the cost of the product alsoPlay a vital role. With the continuous development of computers, CAD technology is consideredComputer aided design has become an indispensable tool for designers. CAD technology is moving from 2D CAD to 3D CAD.Three dimensional design software, engineering and productionAnalysis, calculation, geometry modeling, simulation and experiment, drawing graphics and engineering numbersAccording to library management, generate design documents and other functions. 3D CADTechnology was born toIt has been widely used in the fields of machinery, electronics, architecture, chemical engineering, aeronautics and AstronauticsAnd energy, transportation and other fields, the design efficiency of products has been improved rapidly. Our country CADTechnical research,Great progress has been made in development and popularization,Product designComplete two-dimensional CADThe popularization of technology has ended the history of hand drawing,It has played an obvious role in reducing the intensity of manual labor and improving the economic efficiency.Advantages of 3D design software2.1.1Solid modeling of parts2.1.2The product is easy to modify2.1.3Generating entity assembly drawingTwo point twomouldCAD/CAMIntegrated manufacturingTwo point threeMechanicsCAEFunction application

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Seamless Concrete Pipe for Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords