DN150 Wear-resistant Pipe for Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DN150 Wear-resistant Pipe for Concrete Pump

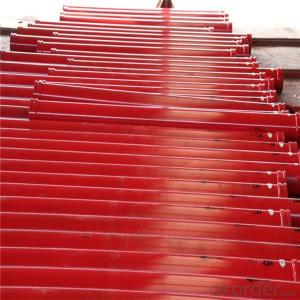

1. Structure of DN150 Wear-resistant Pipe for Concrete Pump:

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

2. Main Features of DN150 Wear-resistant Pipe for Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

3. DN150 Wear-resistant Pipe for Concrete Pump Images

4. DN150 Wear-resistant Pipe for Concrete Pump Specification

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: The strength criterion of mechanical parts design is briefly introduced

- 1, the strength criterion requires that the working stress of the mechanical parts should not exceed allowable stress [Sigma]. The formula is typical: (3-16) lim - ultimate stress of brittle materials by static stress on the ultimate strength, the static stress of plastic materials, the yield limit of zero stress the fatigue limit. S - Safety factor. 2. stiffness criteria mechanical components are subject to elastic deformation when subjected to load. Stiffness is the ability to resist deformation of materials, mechanical parts, or structures subjected to external forces. The stiffness of the material is measured by the external force required to produce the unit deformation. The stiffness of a mechanical part depends on its modulus of elasticity, E or shear modulus, G, geometry and size, and the form of external forces. It is an important work in mechanical design to analyze the rigidity of mechanical parts. For some parts that need to be strictly deformed (such as wings, machine tools, spindles, etc.), stiffness analysis is necessary to control the deformation. We also need to control the stiffness of the parts to prevent vibration or instability. In addition, a spring, such as a spring, must be used to control its stiffness to a reasonable value to ensure its specific function. The stiffness criterion is that the elastic deformation of a component subjected to load is not greater than the allowable elastic deformation. The expression of the stiffness criterion is (3 - 17) y is an elastic deformation quantity, such as deflection, longitudinal elongation (shortening): [y] is the corresponding allowable elastic deformation. The elastic deformation of a part can be obtained by theoretical calculation or by experiment. The allowable deformation depends on the use of the part, and is determined by theoretical analysis or experience.

- Q: I am engaged in the mechanical design work, asks the three-dimensional mechanical component model to download the website.

- To Cadenas partcommunity download, under their own Baidu search, there are hundreds of manufacturers above the product model, the standard parts of all countries, free of charge, just register. Choose the format you want. The format is common.

- Q: I'm going to learn 3D design. I used to just CAD.Excuse me, is it good to learn PRO-E or SOLIDWORK?I mainly used in product design (such as sheet metal parts, machining parts and plastic parts, etc.) is used to design the mould.Also, you can download the best Chinese version of these two software from the Internet, please ask friends about the locationUrgently...

- These two can, there is a director, according to the domestic general situation, usually PROE use more, exchange more convenient, as long as there is a three-dimensional software with skilled, no matter that can be.

- Q: Fixture assembly drawings, detailed parts drawings, design instructions, machining processes, integrated cards, and process cards will be added

- Learn tyrants thing in the community are not practical, in the factory to consider a lot of factors, not necessarily good! Encouraging a pa! Or go to the society to study well!

- Q: Can the bearings used in the design of mechanical equipment be used as part drawings?

- (2) general drawing in section view, when there is no need to exactly express the contour of rolling bearing, load characteristics, structure characteristics, can be rectangular wire frame and cross shaped sign is located in the central line frame upright said cross symbol should not contact with the rectangular frame line, as shown in figure a. The general drawing is drawn in the same way on both sides of the shaft, as shown in Figure B. (3) characteristic drawing and prescribed drawing. The characteristic drawings and rules for rolling bearings are listed.

- Q: I would like to open a small mechanical design company (specializing in the design of mechanical parts, etc.) can you make money?

- Really, the scope of the company's experience is not the design parts ah, better product design! Do you mean the standard parts? There are regular standard parts factory, if it is an industrial design company, that includes product appearance and internal structure design, it can not just design machinery products.If in Beijing, the best fixed source of the project, otherwise it is difficult to survive, the small Beijing design companies have as many as ten, the most famous is "Rococo" design, development of other city is not clear, but the design development in the south is better, the project will also, in Shenzhen for the.

- Q: their own materials, hope that the older generation can be under the guidance of the younger brother, brother, thank you very much

- 1. design is a process of planning, planning, and imagining communicating through visual form.2., human beings transform the world through labor, create civilization, create material wealth and spiritual wealth, and the most basic and important creative activity is creation. Design is the creation of activities that are planned in advance and can be understood as the design, technology, and planning process of any creation.3., first of all, understand the user's expectations, needs, motivations, and understand the needs and limitations of the business, technology, and industry.

- Q: What is the design procedure of mechanical parts urgently ah?!

- The technical design includes the following work: 1. kinematic design. According to the design scheme and the working parameters of the working mechanism, the dynamic parameters of the prime mover, such as power and speed, are determined, and the size and movement parameters of each component are determined. 2. dynamics calculation. According to the result of kinematic design, the load acting on the part is calculated. 3. part design. According to the load and design criterion of parts, the basic dimensions of parts are determined by means of calculation, analogy or model test. 4. overall assembly draft design. According to the basic dimensions of the components and the structure of the mechanism, the overall assembly sketch is designed. On the basis of considering the assembly, adjustment, lubrication and processing technology of parts, the structure and dimension design of all parts are completed. Determine the parts of the structure, size and parts of the relationship between the location, you can accurately calculate the role of the load on the parts, analysis of factors affecting the work capacity of parts, such as stress concentration. On this basis, the main parts should be checked and calculated, such as accurate calculation of shaft strength, life calculation of bearings. According to the result of calculation, the structure and size of parts can be modified repeatedly until the design requirements are met.

- Q: Good mechanical design or good mechanical manufacturing?

- generally refers to some large machinery, such as CNC grinding tools and so on, need to do it yourself, go to practice;

- Q: In the process of mechanical design, those areas should be designed as fillet and when to design chamfer. These materials can be found in those places, and the title of the book is also OK. Thank you!

- Chamfering and roundingIn order to facilitate assembly and operation safety, the shaft ends and holes are usually made into a small cone to remove sharp edges and burrs. This cone is called chamfer.The size of the chamfer can be checked by the standard GB6403.4-86. Generally, the larger the axle diameter and the aperture, the greater the axial size of the chamfer.For the shafts and holes of the ladder, in order to avoid cracks due to stress concentration, the larger parts of the force are often transferred at the shoulder of the shaft and the fillet of Kong Jian, which is called the reverse circle.See: "mechanical design manual" (Third Edition), the first volume, the fifth chapter, parts cold processing, design, process and structural factors

Send your message to us

DN150 Wear-resistant Pipe for Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords