Concrete Delivery Pipe for SANY Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Concrete Delivery Pipe for SANY Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of Concrete Delivery Pipe for SANY Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

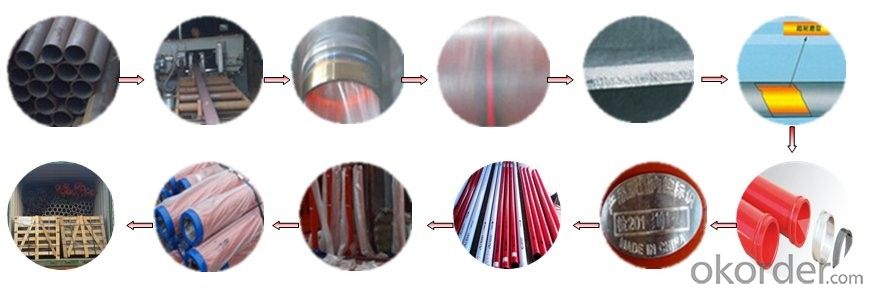

3. Concrete Delivery Pipe for SANY Concrete Pump Images

4. Concrete Delivery Pipe for SANY Concrete Pump Specification

Name | Data |

Material | 45MN2/20#/16MN/Q345 |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

Process | High temperature quenching |

HRC | 65 |

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: 3D MAX must set motion for each object. Is there a 3D mechanical design software that can simulate the mechanical movement of the parts?As long as the specified object is motor, coupling, chain, gear, into the simulation, the three-dimensional map of the motor shaft will rotate, and drives the coupling, keys, gear for the corresponding movement, rather like 3D Max that is the true state of motion to each object design movement performance of this machine combination?

- SOLIDWORKSBut it is also necessary to develop the law of motion relative to 3DMAX, but your modeling is a problem,Can you NURBS? SOLIDWORKS does not support polygon modelingIf I import the file, there's only line segments. I haven't found a better wayIt's better to continue using 3DMAX

- Q: In the design of large machinery, it is to design the parts first, the assembly drawings as well

- First of all, the transmission mechanism must be defined first, and then the strength of the transmission system must be calculated, and then the actual size, gear modulus and so onThen draw parts, assemble, assemble problems, and then change parts

- Q: The strength criterion of mechanical parts design is briefly introduced

- 3. heat resistance criteria, due to friction and other reasons, when the machine is running, the temperature of the machine parts and lubricants will generally rise. Excessive work temperature will lead to a decrease in lubrication effect, and will cause thermal deformation, hardness and strength degradation of the parts, even damage. In the high temperature, metal mechanical parts may be glued and stuck; plastic and other non-metallic mechanical parts may soften, or even melt, and in some cases will cause thermal stress. Heat resistance is generally not the temperature control criterion of mechanical parts exceeds the allowable value, in order to ensure the normal work of the parts, the expression is (3 - 18) in order to improve the temperature control performance, heat dissipation, when necessary, can use water or air cooling measures. 4. vibration stability criteria, when the frequency of excitation is equal to the natural frequency of the object, the amplitude of the object is the largest, the frequency of excitation is different from the natural frequency, and the amplitude of the object is smaller. When the frequency of excitation is close to the natural frequency of the object, the amplitude of the forced vibration is very large. This phenomenon is called resonance. Vibration stability refers to the quality of mechanical components avoiding resonance when the machine is running. In order to prolong the life of the machine, in order to avoid the damage of the shaft and the machine, the vibration stability of the axle is calculated, especially the axis of the high-speed machine.

- Q: And parts, components, institutions, the relationship between the threeIs the key a part?

- parts, but to "the pedals and sprocket" together, and form component. Several components constitute a chain drive mechanism. Similarly, key parts.

- Q: including design originality, manufacturing process, drawing, processing technology, cost calculation, and function

- Design ideas for mechanical parts? Never heard of it. I've only heard of mechanical creativity.

- Q: their own materials, hope that the older generation can be under the guidance of the younger brother, brother, thank you very much

- Knowledge of material knowledge of machine parts is usually required:1., first learn some basic knowledge, such as material mechanics, theoretical mechanics, metal materials, heat treatment, metallographic, hot processing, cold processing.2. then learn more about your work unit product. Technical data of main components, performances, requirements and common materials.3., online access to the same or similar industry related information.

- Q: What is the design procedure of mechanical parts urgently ah?!

- 5. assembly and parts diagram design. According to the structure and size of parts assembly sketches to determine the complete assembly and parts diagram design. (according to the plan to determine the main dimensions, structure design, parts drawing, sorting out the map) four, as the case with technical documentation requirements, design and coding machine calculation manual, manual, standard parts list, purchased parts list, etc. in the conditions of acceptance in the design process, such as a link the problem is feasible or not, need to return to revise the previous design, until the problem is solved. Sometimes, for this reason, even the whole project has to be knocked over. Therefore, the mechanical design process is an iterative process. (standard and outsourcing parts arrangement, specification preparation, acceptance documents

- Q: Before listening to the teacher mentioned that, when the design of components, we should take into account the actual processing capacity of the factory, and some look very simple things, the factory is unable to process! I want to know what the reason is!!!

- Because people are generally from the book, really have actual working experience is not much, you said a few people can personally design processing, now has several high diploma and technical school students in the first 5 years of the stem! So according to processing technology, sometimes do things, such as organic glass with oil and gas drilling is not only different from the design process is not, few people will know!

- Q: Mechanical design, hardness of the workpiece, how to determine, for example, in the drawings, technical requirements of the hardness value how to get?

- 1. the hardness of the workpiece should be determined to determine the hardness of the workpiece for the design according to the working conditions of the workpiece, such as linear bearings for the hard axis, because the shaft and ball contact stress, the equivalent of the bearing outer ring, so the hardness in 60-64HRC, which requires the use of accumulated experience, can also query the relevant information to obtain.2., because of the hardness requirements, so the need for reasonable material selection and heat treatment methods; or linear bearings used for hard shaft, it is necessary to choose the appropriate material Cr15, and the surface high-frequency quenching. Material can be used in the design manual to select materials, and heat treatment processes are required to refer to the Handbook of heat treatment processes.3., as designers, there is no need to be proficient in materials, knowledge, and heat treatment processes, but it should be understood that no mistakes should be made. For example, the choice of 2Cr13 as linear bearings with the hard shaft, that hardening is not to improve the hardness. Or choose the right material, but there is no corresponding heat treatment, the surface hardness is not guaranteed.

- Q: Mechanical design of various parts of the hardness value of how to determine?.

- You send out the request and I'll help you get it! Upstairs answer obvious mistakes, such as 45 steel, the best performance in 39-44HRC, but domestic heat treatment and foreign heat treatment level there are differences, the same hardness, foreign countries are several times more durable than the domestic!

Send your message to us

Concrete Delivery Pipe for SANY Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords