Concrete Pump Hardened Pipe DN125 High Endurable

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 2000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Pump Hardened Pipe DN125 High Endurable

1. Structure of Concrete Pump Hardened Pipe DN125 High Endurable:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of Concrete Pump Hardened Pipe DN125 High Endurable:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

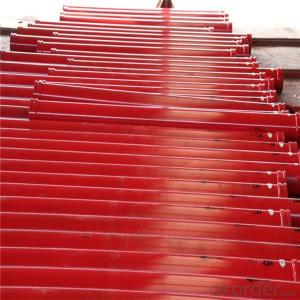

3. Concrete Pump Hardened Pipe DN125 High Endurable Images

4. Concrete Pump Hardened Pipe DN125 High Endurable Specification

Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Max. work press |

Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

Diamond wear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

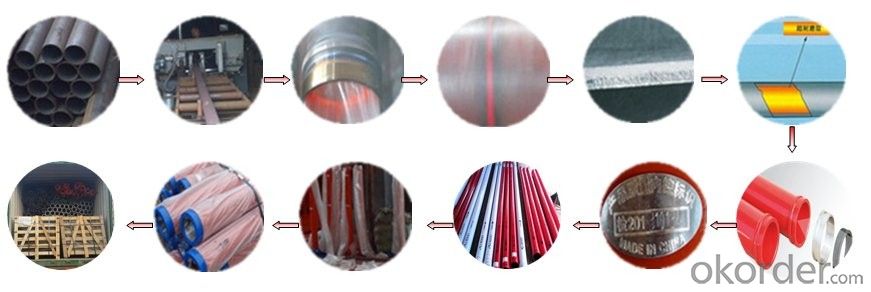

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: How often should concrete pump hydraulic filters be inspected and replaced?

- Regular inspection of the hydraulic filters for the concrete pump is recommended, preferably every three months. However, the inspection and replacement frequency may differ based on the concrete pump's specific conditions and usage. In cases where the pump is operated in harsh environments or extensively used, it may be necessary to conduct inspections and replacements more frequently. Close monitoring of the hydraulic filters' condition is crucial, and any signs of clogging, damage, or wear should prompt immediate replacement. Failure to adequately inspect and replace the filters as required can lead to reduced performance and efficiency of the concrete pump, as well as potential harm to the hydraulic system.

- Q: What are the different types of concrete pump hopper agitator shaft seals?

- There are various types of concrete pump hopper agitator shaft seals, including packing seals, mechanical seals, and lip seals.

- Q: What are the specifications for concrete delivery pumps?

- In the hot season construction, concrete pump to prevent the oil temperature is too high. When the temperature reaches 70 degrees, stop running or take other measures to cool down;

- Q: Can concrete pump spare parts be used interchangeably between different pump brands or models?

- No, concrete pump spare parts cannot be used interchangeably between different pump brands or models. Each pump brand and model is designed with specific specifications and dimensions, so the spare parts need to be specifically manufactured to fit those requirements. Attempting to use spare parts from a different brand or model may result in compatibility issues or even damage to the pump. It is always recommended to use genuine spare parts from the same brand or model to ensure proper functioning and longevity of the pump.

- Q: What is the concrete delivery pump?

- Currently mainly divided into gate valve, concrete pump and S valve concrete pump

- Q: What is the purpose of a concrete pump remote control battery?

- The purpose of a concrete pump remote control battery is to provide power and mobility for the remote control device used to operate a concrete pump. The remote control allows the operator to conveniently control the movements and functions of the concrete pump from a distance, without having to be physically present at the pump itself. The battery supplies the necessary electrical energy to the remote control, enabling it to transmit signals and commands wirelessly to the concrete pump. This allows for greater flexibility and ease of operation, as the operator can move around the construction site while maintaining control over the concrete pump. The battery also ensures uninterrupted operation of the remote control, allowing for efficient and accurate control of the concrete pump's functions.

- Q: What are the common challenges in sourcing spare parts for stationary concrete pumps?

- The common challenges in sourcing spare parts for stationary concrete pumps include limited availability, long lead times, high costs, and compatibility issues with older models. Additionally, the need for genuine parts from reputable manufacturers is crucial to ensure optimal performance and avoid potential breakdowns or safety risks.

- Q: Are there any specific guidelines for the installation of control panels or electronic components in concrete pump spare parts?

- Specific guidelines exist for the installation of control panels or electronic components in concrete pump spare parts. When installing such components, it is important to consider the following guidelines: 1. Protection from Moisture: Electronic components can be damaged by moisture, so it is advisable to install them in waterproof or moisture-resistant enclosures to prevent damage from water or humidity. 2. Vibration and Shock Absorption: To avoid damage, it is recommended to use shock-absorbing mounts or vibration-resistant enclosures to minimize the impact of vibration and shock on control panels or electronic components. 3. Temperature Control: Extreme temperatures can affect concrete pump spare parts, so it is crucial to install control panels or electronic components in a temperature-controlled environment. This may involve using insulation or cooling systems to maintain a suitable operating temperature. 4. Wiring and Connections: Proper wiring and connections are essential for the functioning of control panels or electronic components. It is important to follow the manufacturer's instructions and guidelines for wiring, ensuring secure connections and providing adequate insulation and protection against short circuits or electrical hazards. 5. Accessibility and Maintenance: Control panels or electronic components should be installed in a way that allows easy access for maintenance and repairs. Sufficient space should be left around the components for easy inspection, servicing, and replacement if needed. By adhering to these guidelines, the installation of control panels or electronic components in concrete pump spare parts can be carried out to ensure their long-term functionality and durability.

- Q: Can I get spare parts for concrete pump boom arms and pipes?

- Yes, you can definitely get spare parts for concrete pump boom arms and pipes. There are various suppliers and manufacturers that specialize in providing spare parts for concrete pumps. These spare parts include boom arms, pipes, couplings, gaskets, seals, and other components that are necessary for the proper functioning of a concrete pump. You can search for these spare parts online, where you will find numerous websites and online stores that offer a wide range of options. It is important to ensure that you purchase spare parts from reputable suppliers to ensure their quality and compatibility with your specific concrete pump model. Additionally, there are also local dealers and distributors who stock spare parts for concrete pumps. You can inquire with them or visit their stores to find the required spare parts for your boom arms and pipes. Regular maintenance and replacement of worn-out or damaged parts is crucial for the efficient and safe operation of a concrete pump. By investing in high-quality spare parts, you can extend the lifespan of your equipment and ensure its optimal performance.

- Q: How is the piping of the concrete pipe designed?

- Concrete conveying pipe is fixed, not directly supported on the reinforcing steel bar, and embedded parts, horizontal pipe should be fixed with a certain distance bracket, pad, sling etc, to facilitate the removal of plugging, dismantling and cleaning pipeline; vertical tube should be fixed on the wall or floor slab and column top hole with embedded parts

Send your message to us

Concrete Pump Hardened Pipe DN125 High Endurable

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 2000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords