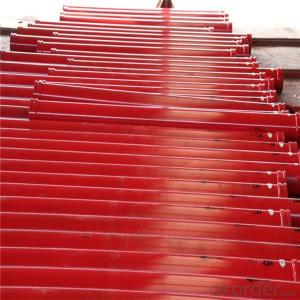

Concrete Pump Hardened Pipe DN125*4.6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 2000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product parameters:

Name | Data |

Material | 45MN2/20#/16MN/Q345 etc |

Thickness | According to customer requirements |

Color | red, white , etc. |

Using life | 20.000m³-80.000m³ |

Weight | 43kg,48kg,69kg |

Length | 1-6m, according to customer requirements |

Model | DN125,DN150 |

Flange | SK/ ZX /FM flange |

Painting | Electrostatic Spraying Epoxy Paint |

Welding | Smooth welding between straight pipes and flanges |

Process | High temperature quenching |

HRC | 65 |

Product Specifications Model Description:

| Name | Structure | Specification | Weight | Life time | Impact force | Notched bar impact strength | Maxture work press |

| Normal wear resistant pipe | Single | DN125*3000mm | 48kgs | 6000 - 8000 | ≥45 | ≥27 | 36 bar |

| Economic wear resistant pipe | Single | DN125*3000mm | 45kgs | 18000 - 22000 | ≥47 | ≥28 | 93 bar |

| Construction wear resistant pipe | Single | DN125*3000mm | 45kgs | 20000 - 25000 | ≥47 | ≥28 | 93 bar |

| Diamondwear resistant pipe | Single | DN125*3000mm | 44kgs | 25000 - 35000 | ≥47 | ≥38 | 93 bar |

| W12-5 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 50000 - 60000 | ≥ 42 | ≥25 | 59 bar |

| W12-8 wear resistant pipe | Twin | DN125*3000mm | 43kgs | 60000 - 80000 | ≥ 43 | ≥25 | 59 bar |

| GX350-1 wear resistant pipe | Twin | DN125*3000mm | 44kgs | 80000 - 100000 | - | - | 34 bar |

| GX350-2 wear resistant pipe | Twin | DN125*3000mm | 68kgs | 120000 - 150000 | - | - | 76 bar |

Our services:

1, In case of quality problem the company provide free replacement

2, Provide technical support for free

3, Provide consumers with regular visits

4, Ensure the supply of ancillary parts

5, The company passed the ISO9000 certification, the product through 3 c certification in full compliance with national standards

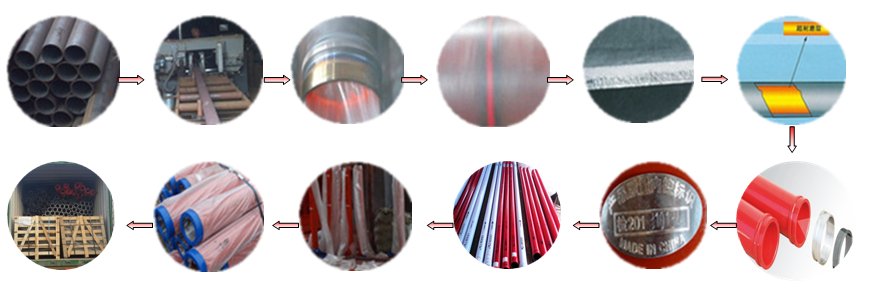

Packaging and transport:

No.1 Export standard packing

No.2 Seaworthy packing

No.3 other ways or according to the customer demand

Why choose us:

1. We are a comprehensive manufacturing and trading company.

2. Our company is one of the biggest manufacturing and trading companies in China.

3. We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

4. We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

5. We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: is it the first overall drawing, or first out parts drawings, and then assembly?

- Personal habits ~ ~ general circumstances, the first overall map, and then parts map ~!

- Q: The strength criterion of mechanical parts design is briefly introduced

- 1, the strength criterion requires that the working stress of the mechanical parts should not exceed allowable stress [Sigma]. The formula is typical: (3-16) lim - ultimate stress of brittle materials by static stress on the ultimate strength, the static stress of plastic materials, the yield limit of zero stress the fatigue limit. S - Safety factor. 2. stiffness criteria mechanical components are subject to elastic deformation when subjected to load. Stiffness is the ability to resist deformation of materials, mechanical parts, or structures subjected to external forces. The stiffness of the material is measured by the external force required to produce the unit deformation. The stiffness of a mechanical part depends on its modulus of elasticity, E or shear modulus, G, geometry and size, and the form of external forces. It is an important work in mechanical design to analyze the rigidity of mechanical parts. For some parts that need to be strictly deformed (such as wings, machine tools, spindles, etc.), stiffness analysis is necessary to control the deformation. We also need to control the stiffness of the parts to prevent vibration or instability. In addition, a spring, such as a spring, must be used to control its stiffness to a reasonable value to ensure its specific function. The stiffness criterion is that the elastic deformation of a component subjected to load is not greater than the allowable elastic deformation. The expression of the stiffness criterion is (3 - 17) y is an elastic deformation quantity, such as deflection, longitudinal elongation (shortening): [y] is the corresponding allowable elastic deformation. The elastic deformation of a part can be obtained by theoretical calculation or by experiment. The allowable deformation depends on the use of the part, and is determined by theoretical analysis or experience.

- Q: Does the SolidWorks mechanical design engineer paint parts individually or draw parts in an assembly?

- In the overall design of the product, can put each parts of a product are designed, then get the assembly components, after assembly to check whether all parts of the design meets the requirements, whether interference exists, if you need to modify, change are separate parts, and then in the assembly test again until the end, fully meet the design requirements. Since the whole process is down (component), it is impossible to plan the product from the very beginning, and how many parts of the product can be determined only after all the parts have been completed. This method will be modified because there is no prior to the careful planning and effective. This bottom-up design can be used in the case of ready-made products, and in the case of a single product range. But in the new product design or product series rich and changeful circumstances, it seems very inconvenient.TOP-DOWN design refers to the analysis of the finished product, and then down design. The main frame of products as the main component, and the product is decomposed into components, sub assemblies, and then identifies the main component element and its related characteristics, finally understand the relationship between components and internal components, and to evaluate the product assembly. With this information, you can plan and design and grasp the overall design intent in the model.It can manage large components, but also can effectively grasp the design intent, make a clear organizational structure, not only can quickly transfer the design information, in the same design group to achieve the purpose of sharing information, can also transfer the same design information in the design team between different, to the purpose of cooperative combat. Thus, in the early stages of design, through rigorous communication management, can make different design departments synchronous product design and development.

- Q: Force calculation is in the component diagram, the size of the component is obtained by force, and if you don't draw the parts first, how do you draw the general plan?How do you calculate the force of a part if you draw the part diagram first and don't know the size relation between the parts?

- First draw a diagram, determine the location of each part, then draw the parts drawing, and finally the general drawing

- Q: What are the basic criteria for the design of mechanical parts?

- (2) the demolition of the old machine parts of the work, the stress components and their connections, should meet a predetermined maximum load enough strength, stiffness and stability during normal operation should not occur due to the work cycle or stress or fatigue fracture times have broken, excessive deformation or collapse; also must considering the stability of the whole mechanical equipment under the premise of the anti overturning wind or anti slide, especially those with mechanical vibration displacement load or its expected quality uneven distribution.(3) adequate adaptability to the use of the environment. The work equipment of the demolition of the old machine parts must be used to the environment (such as temperature, humidity, air pressure, wind load, snow load, vibration, and electrostatic, magnetic and electric fields, radiation, dust, microorganism, animal and corrosive medium) has enough ability to adapt, especially anti corrosion or erosion, aging wear, anti-interference ability, not because the electrical components affect the physical, chemical and biological caused by accident.

- Q: How to design the power assisted robot, mechanical structure and pneumatic part, please point out, thank you!

- Professional production, you can go to understand, draw on for reference

- Q: Why do the design of mechanical parts (flanges and elbows) be based on the yield limit?

- In order to reach the yield limit, it is the failure of the material to begin the elasticity, and the elastic-plastic stage has been started. This is designed according to GB150-1998. You can look at the analysis data of the blasting process of the steel

- Q: including design originality, manufacturing process, drawing, processing technology, cost calculation, and function

- Estimate is very suspended, needless to say, free of charge, that is, you go to buy, nor necessarily sell you. This is someone else's technical secret, it's not good to go inside for several years.

- Q: I would like to open a small mechanical design company (specializing in the design of mechanical parts, etc.) can you make money?

- I really heard about this kind of company. Key: business promotion, design experience, additional experience.If you can get enough money, if you open the advertising skills and experience in mechanical design, powerful enough if you can tell the customer to design the end where I can get a good and where can I find a cheap and can ensure the processing precision and efficiency of the manufacturers, do it.On the contrary, think twice!

- Q: In the process of mechanical design, those areas should be designed as fillet and when to design chamfer. These materials can be found in those places, and the title of the book is also OK. Thank you!

- The edges of the non machined surfaces of various castings shall be designed as arc R, and the sharp edge of the lathe shall be chamfered 45 degrees. These are in the design manual, you are new, and when you are free, look at the design manual.

Send your message to us

Concrete Pump Hardened Pipe DN125*4.6mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 PCS

- Supply Capability:

- 2000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords