Diamond Plate Aluminum Sheets for Roof Phoenix

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

- Q: What's the maximum size of 3 mm thick aluminum sheet?

- To see what is your production process requirements? If it is hot extrusion, the width of the largest flatness requirements under the condition of low at about 300mm. If the processing technology of aluminum strip is hard to say, to see the production capacity of the equipment (the size and size is the maximum size of the majority in the 1.2) to 1.5 meters wide, the length of one hundred meters above

- Q: Are aluminum sheets suitable for signage applications?

- Yes, aluminum sheets are suitable for signage applications. Aluminum is a lightweight and durable material, making it perfect for outdoor signs that need to withstand various weather conditions. It is resistant to rust and corrosion, which ensures the longevity of the sign. Aluminum sheets can be easily customized and cut into different shapes and sizes, allowing for versatile and creative signage options. Additionally, aluminum is a great material for digital printing and can provide high-quality graphics and images. Overall, aluminum sheets offer excellent durability, versatility, and aesthetic appeal, making them a popular choice for signage applications.

- Q: Can aluminum sheets be used in the aerospace industry?

- Yes, aluminum sheets can be used in the aerospace industry. Aluminum is a lightweight material with excellent strength-to-weight ratio, making it a popular choice for various aerospace applications. It is commonly used in the construction of aircraft structures, such as fuselages, wings, and panels. The use of aluminum sheets in the aerospace industry offers several benefits, including reduced fuel consumption due to the weight savings, improved maneuverability, and increased payload capacity. Additionally, aluminum exhibits good corrosion resistance, which is crucial for aircraft exposed to harsh environmental conditions. Overall, aluminum sheets are widely utilized in the aerospace industry for their favorable properties and performance.

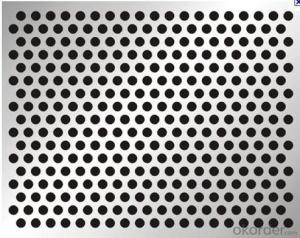

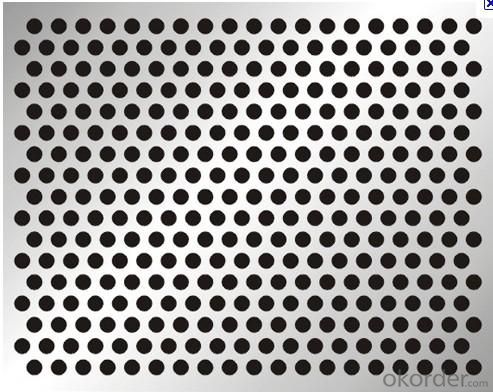

- Q: Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves punching holes or creating a pattern of holes in a material. Aluminum is a versatile and malleable metal that can be easily perforated using various methods such as punching, drilling, or laser cutting. Perforating aluminum sheets can serve multiple purposes such as allowing for airflow, reducing weight, enhancing aesthetics, or creating filtration systems. The size, shape, and arrangement of the perforations can be customized to meet specific requirements and design preferences. Overall, aluminum sheets can be effectively perforated to enhance their functionality and visual appeal.

- Q: What is the flexural modulus of aluminum sheets?

- The flexural modulus of aluminum sheets refers to the measure of stiffness or rigidity of the material when subjected to bending. It quantifies how much the material will deform or bend under a given load. The flexural modulus of aluminum sheets typically ranges between 70 and 79 GPa (Gigapascals).

- Q: Are aluminum sheets resistant to impact?

- Aluminum sheets, in general, have a resistance to impact. With its lightweight nature, aluminum is a metal that possesses both strength and toughness, enabling it to endure impact forces. It boasts remarkable energy absorption qualities, facilitating the absorption and dispersion of impact-generated energy, thereby reducing harm to the sheet. Moreover, aluminum sheets can be fortified further through techniques like heat treatment or alloying, enhancing their impact resistance. Nonetheless, the impact resistance of aluminum sheets may fluctuate based on the particular alloy and thickness employed.

- Q: I need to make an aluminum cylinder out of 1/8 6061 plate and tube. I don't have a TIG setup and was considering using Bernzomatic aluminum soldering rods. The cylinder will be pressurized from 20-60 psi. Assuming a clean job, is this pressure ok? How much pressure can the joint take? Also, although the solder does not need flux, should i use it anyway?

- to your setup i might merely persist with the iron. It would not sound like the burden mark downs is going to be properly actually worth the greater suitable probability for a on a regular basis motive force. forged iron is merely greater rugged and can take greater abuse than aluminum. Aluminum has its place yet its no longer in a on a regular basis motive force like it variety of feels you're development.

- Q: Are aluminum sheets suitable for solar reflectors?

- Certainly, solar reflectors can indeed make use of aluminum sheets. The construction of solar reflectors extensively relies on aluminum owing to its remarkable reflectivity and durability. By virtue of its reflective characteristics, aluminum effectively redirects sunlight onto solar panels or other solar equipment, thereby enhancing energy absorption. Moreover, aluminum is lightweight and resistant to corrosion, making it an excellent choice for outdoor use. Furthermore, its cost-effectiveness and ease of fabrication greatly contribute to its widespread adoption in the solar sector.

- Q: What are the distinctions between standard and custom-made aluminum sheets?

- <p>Standard aluminum sheets are mass-produced with fixed dimensions and specifications, making them readily available and cost-effective. They are suitable for common applications where specific dimensions are not a priority. Custom-made aluminum sheets, on the other hand, are tailored to meet specific requirements regarding size, thickness, and other properties. They offer flexibility for unique applications but may be more expensive and have longer lead times due to the specialized manufacturing process.</p>

- Q: Hi guys. I was just wondering if you can give me some tips or information on what you know about painting on metal. The metal that is of concern is aluminium and I would like to put a stencil over this aluminium and just blast it with a can of krylon. Of course...this aluminium piece is actually part of the housing for my cell phone so doing it like this would probably not be right and the paint would probably wear out. I am mainly interested in finding out what kind of paint to use, what tools i need, and how to achieve an extremely! durable! matte finish because this phone is thrown around and going in and out of my pocket the paint will have to withstand getting rubbed down everyday by my pockets.That was a very long question, thanks for bearing with me and thanks in advance for those who provided me with an answer/thought. THANKS!

- Krylon is a very tough metal medium and the newer product they have at wal-mart in the paint section is fantastic. I don't know about rustoleum, other than another brand, but you could use a coat of polyutherine matte varnish. You can get this at wal-mart in the paint section or a hardware store. It will seal anything.

Send your message to us

Diamond Plate Aluminum Sheets for Roof Phoenix

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords