Dead-Burned Magnesite Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

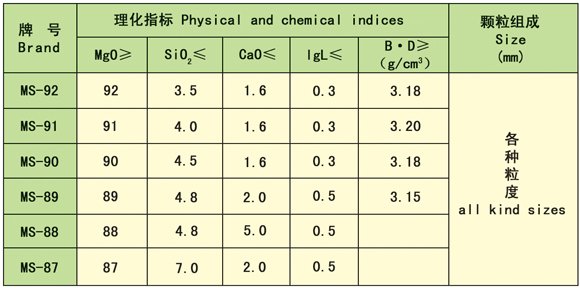

| Place of Origin: | Liaoning, China (Mainland) | Shape: | Block | SiO2 Content (%): | 3.5-7.0 |

| MgO Content (%): | 87-92 | CaO Content (%): | 1.6-5.0 | Model Number: | M-DBM |

| Brand Name: | CNBM |

Packaging & Delivery

| Packaging Details: | 10-25kilogram 5 layers craft paper bags, the craft paper and plastic compound bags; 40-50 kilograms PP bag, 500 and 1000 kilograms PP bag packing. We can also pack according to users' requirements |

| Delivery Detail: | Within 1 month |

Specifications

1.High purity Large crystal grain Compact structure

2.Strong resistance to slag material

3.Good thermal shock resistance

Dead-burned magnesite is selected from natural magnesite, it is produced by mine-selecting, purifying, calcining in shaft kiln. It is an ideal material for unshaped refractory material, the final products are used in open hearth furnace, eletric furnace bottom and furace's lining tamping.

Details are as follows:

Our company has processed various kinds of magnesia. As 20 years passing, our products of magnesite are widely used in many industrial fields of areas the world. Any question, please feel freely to contact us.

Magnesia is divided into sintered magnesia, light burned magnesia, fused magnesia three categories.Magnesia refractory material is one of the most important raw materials, aluminum used in the manufacture of all kinds of magnesite brick, magnesite brick, ramming material, repairing, etc.Contain a more impurities, are used to construct steel furnace bottom, etc.Sand in the main ingredients for magnesium oxide, impurities such as CaO, SiO2, Fe2O3, magnesium oxide as basic oxide, melting point is 2800 degrees, after the high temperature heating into stable cubic crystal, commonly known as periclase.By magnesium hydroxide by high temperature calcination, hydration resistance ability.Sintered magnesia is mainly composed of magnesite, magnesite or water from the water extract of magnesium hydroxide by high temperature calcination.Hydration resistance ability.Magnesite calcination under 700-950 ℃ is escaping CO2, magnesite as soft porous loose material, cannot be used for refractory material;Magnesite through 1550-1600 ℃ calcination so-called burned magnesia said sintered magnesite.Light burning magnesium powder is bending, compression, high strength, hard, gelled material, widely used in national defense, medicine, chemical industry, paper making, shipbuilding and other industries.In the building materials industry produce tire sub board, particle board, heat preservation columns, railing, artificial marble, asbestos tile, ordinary tiles, wall panel, laying on the ground.With the progress of science and technology, light burning magnesium powder application more widely, civil products, light and heavy machinery packing boxes, packaging can do sill, high-temperature refractory material, also can make beautiful luster strong furniture, in the machinery industry to do model.

- Q: Technical scheme of refractory for refuse incinerator

- Design of refractory for incineratorAccording to the condition of incinerator, the requirements of refractory, the temperature of each part and the temperature of outer wall of shell are discussed. The scheme for using refractory materials is as follows:The furnace body is made of two layers of structure, that is, 114mm thick clay brick is built near the steel shell, and the lining is made of 134mm thick graphite brick.

- Q: Does anyone know the difference between refractory and thermal insulation material?

- I will give you a relatively simple analysis. Refractory can bear above 1,200 degrees centigrade, but some refractory is not insulated. For example, refractory brick can be directly in contact with heat source, but it has little insulation effect. Refractory includes ceramic fiber, high silica and so on. And they can be also insulated. But insulation effect is not so good as insulation material. Insulation material generally can bear below 800 degrees centigrade, and it is large in thermal resistance, low in heat conductivity coefficient and high in porosity factor, thus reducing heat loss. Briefly speaking, insulated material is to store most heat, and just let a small quantity of heat run of through air, thus insulating heat. Refractory includes glass fiber, rock wool, aerogel blanket and so on.

- Q: What are the meanings of azs, 34% and ec in fused brick?

- The fused brick, also called zircon corundum brick, is shorted as AZS for three chemical components in Al2O3-ZrO2-SiO2 ternary diagram. I don't know the meaning of EC.

- Q: what are the requirements of fireproofing material?

- The producing process of fire and moth proof wood: firstly, put general wooden materials into solution with calcium, aluminum and other cations, then soak it into the solution with phosphate radical, silicate and other anions. Thus, the two ions will be carried out chemical reaction in the wood, forming a ceramic-like material, and intimately fill the voids of cells, so that the wood has the fireproofing and mothproof properties.

- Q: The development prospect of fire-resistant material

- I also want to know, who can say, thanks all the way.

- Q: Does refractory belong to stone, building materials or other?

- Refractories belong to organic non-metallic materials.

- Q: Which kind of furnace hearth refractory is better?

- hearth selected material] hearth material must be durable, high temperature resistant, general selecting masnory made of refractory cement, silicon carbide refractory products, mullite or multicrystal mullite (which is the general term of minerals composed of a series of aluminum silicate, mullite is only stable binary compound in the Al2O3-SiO2 system) etc.. [hearth] is a three-dimensional space surrounded by furnace walls for combustion of the fuel. The funtion of hearth is to ensure the fuel to burn as far as possible, and to cool the gas temperature of the hearth exit to the allowed temperature of convection heating surface safe operation . Therefore, the hearth should have sufficient space and adequate heating surface. In addition, there should be reasonable shape and size in order to fit the burner and the organize aerodynamic field inside the furnace to prevent the flame from adherence, dashing walls and have high fullness and eve wall thermal load.

- Q: Who knows what material is in the center of fireproof rolling curtain?

- Material and the type high silica cloth as curtain, side rails, with galvanized steel in its end and stainless steel two kinds of materials with double curtain in the end I hope my answer can help to you

- Q: What is refractory?

- Refractory is an inorganic nonmetallic material with minimum refractoriness of 1580 ℃. Now, refractory is not defined merely by judging that whether its refractoriness is at above 1580 ℃. Currently, refractory, an inorganic nonmetallic material, are widely used in metallurgy, ceramics, power and other industrial fields.

- Q: what materials can make external wall fireproofing paint have the fireproofing effect

- Adding flame retardant or fire retardant materials can be fireproofing, which commonly referred to as the external walls of fire retardant coating or fire retardant coating. Principle: Fireproof paint itself is flame-retardant or non-combustible, so that the protected base material can not directly contact with the air in order to the ignition delay and reducing the burning speed; except that, it also has a lower thermal conductivity, which can delay the transfer of flame temperature to the protected base material; fireproof paint thermal can decompose non-combustible inert gas by heating to dilute the thermal decomposition of combustible gas in protected object, making it difficult to burn or slow down the speed of burning.

Send your message to us

Dead-Burned Magnesite Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords