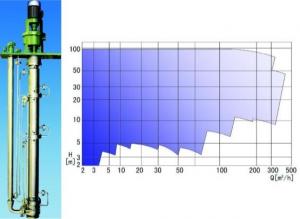

CTN / -H,Radially split, vertical shaft submersible pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Design |

Overview of technical data

| Type of impeller | Radial; Closed |

| Maximum drive rating | 290 kW |

| Impeller material (EN standard) | JL 1040; 1.4408 |

| Type of bearing | Rolling element and plain bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum speed of rotation | 3. 500 1/min |

| Maximum flow rate | 980 m³/h |

| Maximum discharge-side pressure | 16 bar |

| Top plate | Yes |

| Casing material (EN standard) | 1. 4408;JL 1040 |

| No. of impeller entries | Single entry |

| Casing material | Cast iron; Stainless steel |

| Minimum flow rate | 2 m³/h |

| Suction characteristics | Non- priming |

| Drive voltage | Low voltage |

| eClass assignment | 36410000; 36410100;36410101 |

| Pump set location | Dry installed, floodable |

| Heatable | Yes |

| Max. permissible fluid temperature | 300 °C |

| UNSPSC classification | 4015150300 |

| Main applications | Industry and process engineering |

| Type of installation | Stationary |

| Type of casing | Volute casing |

| Type of connection | Flange |

| Type of lubrication | Grease / Oil lubrication |

| Type of drive | Electric motor |

| Installation position | Vertical |

| Shaft material (EN standard) | C45SH+ S;1.4571 SH |

| Type of coupling | Direct |

| Shaft seal type | Gland packing; Mechanical seal |

| Maximum head | 135, 00 m |

| Maximum rated pressure (discharge) | PN 16 |

| Minimum head | 3, 00 m |

| Nozzle position | Variable |

| Casing partition | Radially split |

| Maximum submergence | 9. 500 mm |

- Q: Hi,I want complete manufacturing detail of USB Pen drives, flash disk, Mobile Memory card etc. I searched it through internet but unable to find any information which satisfies the need. Anybody could please tell me the procedure ,how can i start manufacturing of pen drive in india.I also need the machionary required for the assembling purpouse. so, where i would get all these things.please help me... please.sorry for the bad english..

- I think this technology is not available in India. Generally these things are imported from China.

- Q: What are the characteristics of gear transmission compared with other mechanical drives?

- The disadvantage is that the manufacturing and installation requirements are high, can not be buffered, no overload protection, and there is noise.

- Q: What mechanical keyboard is better for playing lol?

- Cheaper with Kay cool 104, magic duck 2108, and so on, between 300 and 500, mid-range with Logitech G710, magic duck 9108, mid-range cherries, 700 - 900

- Q: Which of the following is considered to be capital (physical)?

- Machinery. Physical capital is any form of wealth capable of being employed in the production of more wealth. Hence, machinery makes more of a product you can sell and make money.

- Q: How else might they have expressed their grievances? would other kinds of active have been more successfull?

- syazwani.. apabila anda mendapat jawapan yg betul tentang soalan yg diajukan.. saudari akan mendapat 4.00 didalam subjek Engineering Society!!!! YYYYeeeeehhhhaaaa!!!! Hidup polymer!!!!

- Q: How is cantilever technology used in heavy machinery?

- anytime the load is extended out from beyond the structure, for example: 1 container cranes 2 shiploaders 3 ship unloaders 4 building a bridge over empty space (river, gully, road, railways) from both sides, especially evidenced in fixed stay bridges where the next segment is attached to the previous construction although the shooting bridge takes some of the loads 5 diving board at a pool

- Q: being my mind will be wasted in lala land.....with god

- It sounds like when you do believe in God it will be too late for you. You won't even think about driving a car where you will be going.

- Q: Is there any websites besides Craigslist where i can post my Farm machinery so i can sell them?

- Some local newspapers have free ads but Ebay has a free classified site where you can list items in a local area.

- Q: 7th grade HW

- People's response to alcohol varies widely. THere are some people, I think 'tissue tolerant' is the term, who do not get drunk as they drink, up to the point they die of alcohol poisoning.

- Q: Well, the seasons are changing, it's getting colder. Sooner than later I won't be able to go outside to ripstik, jump rope or ride my bike. So, Does anyone have any ideas for an indoor cardio routine for a 15 year old girl? I don't have access to any machines and it can't be to obvious because my family makes fun of/gets shocked if they learn I workout. (Tried telling my mom I do a strenght training workout, she bugged out)

- acutely cold weather is perfect for cardio workouts do to the lack of air u get so u breath faster shorter breaths while working out but if u are stuck indoors anything u can do to get your heart rate up and pumping . etc dancing , running in place , if you know anything about football , do up downs or you could look on youtube for more and better workouts

Send your message to us

CTN / -H,Radially split, vertical shaft submersible pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords