Corundum Mullite Refractory Bricks for High Hot Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

In order to catch the rapid increasing demand of grinding media and provide full series to customers,we have developed grinding media with 92% AI2O3,75% AI2O3 AND 65% AI2O3.The technical data of each series is listed as following table.

With overwhelming merits in higher density,more regular shape,easily classifying and assorting,superior grinding efficiencies and competitive price prior to natural cobble stones and conventional grinding media,our Alumina Grinding Media are excellent for grinding processing of ceramic bodies and glaze materials in tile industries and surface polishing of the ceramic bearing applicant.

Specifications

1.Excellent corrosion resistance

2.The alumina content is over 96%

3.Used in glass furnace

Features

1.High density

2.Strong corrosion resistance

3.Good slag resistance

4.Low permannent liner change on reheating

Application

High purity corundum brick is usually used in petrochemical industry. In addition, it is also adopted as high temperature interlayer between AZS ans basic bricks in order to avoid the reaction of interface at high temperature.

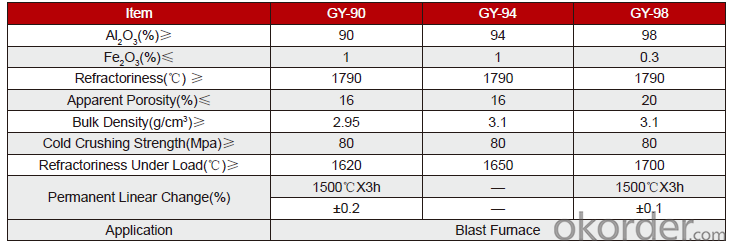

Physical properties and chemical composition

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How much is a thermal brick?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q: What are the advantages of refractories?

- The castable refractory is a refractory product with a certain shape after being melted at high temperature by a certain method. Neutral refractory is refractory material which is difficult to react with acid or alkaline slag at high temperature, such as carbon refractory and chrome refractory. Some of the high alumina refractories are also attributed to this category.

- Q: What's the jade stove for?

- Is it a furnace made of corundum or a furnace for smelting corundum?Corundum brick stove is commonly used as a refractory material sintering furnace, can be fired refractoriness in refractories, below 1700 degrees such as brick, corundum brick, brick, alumina hollow ball and so on

- Q: Wave tile and throwing glaze, tile which good?

- Vitreous tile is all ceramic tile, the material is hard, strong wear resistance, smooth finish is very good, in general, looks very bright. Microcrystalline brick, corundum brick Market said, they really mean bohuazhuan. Because of its low water absorption and high strength and hardness, glazed tile has been widely used. Many hotels, shopping malls and office space are widely used glass tile.

- Q: What refractory materials are used in industrial furnaces?

- Economically, it is necessary to do technical and economic analysis when selecting materials reasonably. Under the premise that the technical indexes agree with the working conditions of the furnace, the refractory materials with low quoted price should be used as much as possible, without high-grade finished products. To think about whether to make self (such as irrigation, refractory concrete) as far as possible to repair old.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- Refractory brick is non-metallic materials can be classified according to a kind of inorganic material, high aluminum brick, clay brick, magnesia brick, corundum brick, mullite bricks, silicon carbide materials such as brick, high alumina brick is used as a relatively wide range of products in accordance with the refractory brick high alumina refractory materials by high aluminum brick is generally divided into Al2O3 content three: I - II - >75% Al2O3 content; the content of Al2O3 is 60 ~ 75%; III - Al2O3 content from 48 to 60%.

- Q: What kind of refractory material will be used in the glass kiln?

- High temperature & glass corrosion performance of the brick is slightly lower than that of chromium oxide, also by isostatic pressing forming method, its technical indicators ZrO2>65%, <2.0% porosity, volume density of about 4.25g/cm3, the temperature in E glass is higher than 1370 DEG C have erosion. Used in the E glass melting pool unit kiln glass temperature slightly lower at the end of the transition path, forming the bottom of the pool and forming path path flow tank and bushing support brick etc.. In addition, the dense zirconia brick is used as the backing brick of the dense chrome brick.

- Q: Ask for help about the phase of refractory material

- Binding phase. The binding phase is the phase outside the main crystal phase or the main crystal phase and the sub crystalline phase. The binding phase can be made up of either a fine crystal or a glass phase or a composite of the two. Such as the combination of magnesia brick, magnesia chrome brick, magnesia brick and other basic refractories in phase is composed of crystal matrix; silica brick, clay brick is made of glass phase in the form. When the matrix is formed at high temperature, the liquid phase is low, and the viscosity of the liquid phase is low and the quantity is large, the production and properties of refractory products are essentially controlled by the substrate.

- Q: What kind of rock is corundum produced?

- If Ti4+ and Fe2+ containing a small amount of blue, a sapphire; containing six symmetrically distributed acicular rutile or other inclusions in some crystals, can produce six star awn, known as star ruby or sapphire stars, are precious stones. Corundum is vitreous luster with no cleavage, but cracks occur because of the presence of poly twin crystals that are often formed by the base or face of a face. Specific gravity 3.98. Of relatively low silicate igneous and metamorphic rocks and common in alluvial deposits. The U.S. state of North Carolina and Georgia, Russia's Ural mountains, South Africa as the main origin of the transvaal.

- Q: What can zirconium sponge do for those industries?

- Zirconium metal, also known as sponge zirconium, silver gray metal, the appearance of steel, shiny; melting point 1852 points, sub points, boiling point 4377 density 6.49. Zirconium is easy to absorb hydrogen, nitrogen and oxygen; zirconium has a strong affinity for oxygen; at 1000 DEG C oxygen dissolved in zirconium can make its volume increase significantly. Zirconium is relatively stable in the air; powder zirconium is easy to burn; fine zirconium wires can be ignited by matches; at high temperatures they can be combined directly with dissolved oxygen, nitrogen and hydrogen.

Send your message to us

Corundum Mullite Refractory Bricks for High Hot Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords