Corundum Mullite Bricks for Refractory Applications

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Factory of Corundum Mullite Bricks for Refractory Bricks

Corundum bricks is widely used in oil gas gasifier, ethylene-generated furnace, and ammonia decomposing furnace in petrochemical industry, carbon black reactor in chemical industry, and high temperature kilns in refractories and ceramics industry.

Corundum bricks has gained the Third Prize of Science & Technology Progress from Sinopec and the former Ministry of Metallurgy Industry.

The brick has been used in the thermal equipment of domestric made or imported. It has been exported and used in German Texaco gasifier with good performance.

Product Applications:

Corundum Mullite Brick are ideal for use in the below applications

Corundum mullite brick is mainly used as superstructure, feeder channel and cover plate in glass furnace. It can also be used as lining of high-temperature kiln and mesothermal carbon black reactor, the shed bar of kiln car, pusher plate of electronic magnetic material industry, etc.

Product Advantages:

CNBM has success in its Corundum Mullite Brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

1.High refractoriness under load

2.Excellent corrosion resistance to both acid and alkali

3.Good thermal shock stability

4.High density

5.Neutral material

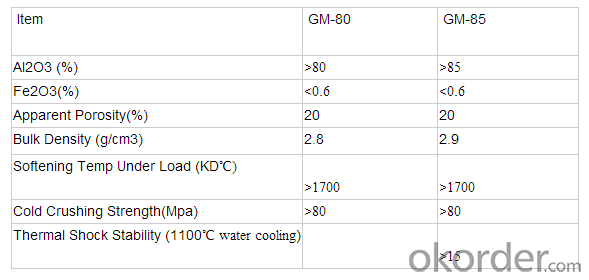

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

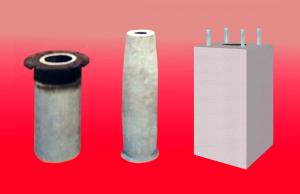

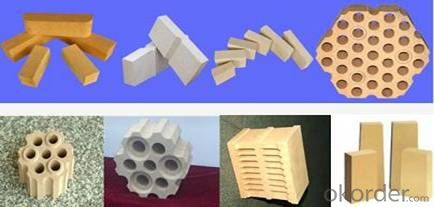

Product Picture

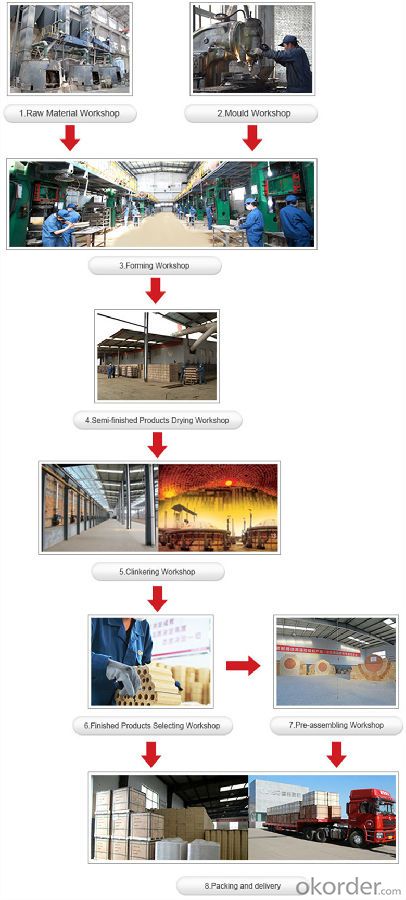

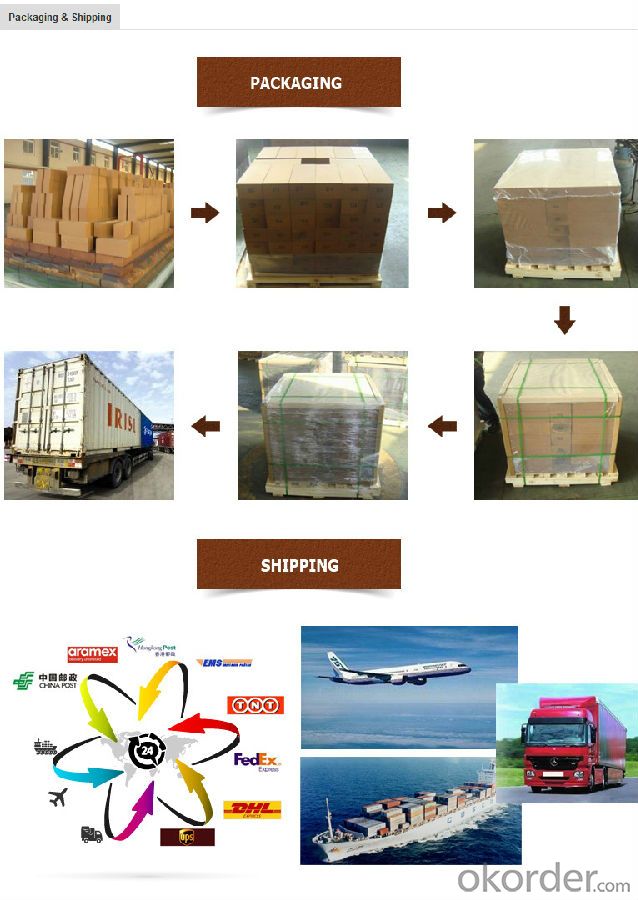

Produce Processing

- Q: What is the main component of corundum?

- Corundum is mainly used in advanced grinding materials, watches and precision mechanical bearing materials. A ruby based artificial crystal used as a laser emitting material. Ruby and sapphire are corundum minerals. Except for the starlight effect, only translucent transparent and vivid corundum can be used as gems. The red is called ruby, while the other tones of corundum are commercially referred to as sapphires.

- Q: What does refractory consist of?

- According to the shape of the product is shaped and unshaped refractory materials two categories, according to the chemical properties of acidic, neutral and alkaline refractory materials three categories, commonly used as refractory material of alkaline and neutral, such as magnesia, alkaline burned magnesia brick, magnesia chrome brick, magnesia calcium brick, high alumina brick, corundum neutral brick, clay brick, including: unshaped castable, ramming material, gunning material, coating material, dry vibration material etc..

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- In fact, a kind of ceramic cup of blast furnace refractories, application in blast furnace bottom and hearth contact steel lining using a layer of non carbon refractory materials, such as Theron with corundum brick, corundum mullite and synthetic mullite bricks etc..

- Q: What equipment is used for producing diamond blanks? How much is the investment?

- Plus all the cables fifty thousand. Steel 10000 yuan. Corundum bricks; insulating bricks; clay bricks, these three require more than ten thousand. The electrode is about one hundred thousand. It's just an investment in an electric furnace. Together with the rear section processing and raw materials need hundreds of thousands of.

- Q: Wave tile and throwing glaze, tile which good?

- These two tiles have their respective advantages and disadvantages, in fact, to say which kind of good, mainly depends on the decoration of personal preferences and the location of the shop. If it is only the shop wall, then design and pattern rich whole glazed tile is good, it can make the room impressive, improve decorative effect, make the decoration style to fit the characteristics of his personality. In addition, clean up is relatively easy, not easy to contaminated with oil stains and other pollutants. If it is laying floor tiles, tile Douglas suggested the use of tiles, tiles of good antiskid effect, water absorption rate is relatively low, so the kitchen toilet bathroom and other wet places is not easy to water seepage, improve the convenience of life.

- Q: Expansion ratio of lightweight corundum refractory bricks

- Now with the production of lightweight foam corundum brick, basically still meters with molding casting, moulding after together with die in the drying room drying in 60~70 C 4 days of release, then the appropriate drying, finally after 1300 and 1550 C firing, the total burning time: 50~60h. Light corundum brick after firing is usually not the size and shape of accurate, so that products after the kiln to mechanical or manual cutting, can be made into a density of 0.8 - 1.3g/cm3, 4MPa compressive strength and porosity, the thermal conductivity of 70%~80% 0.17W/ (M - K), light-weight corundum brick use temperature of 1500~1700 DEG C.

- Q: What refractory materials are used in industrial furnaces?

- Refractory materials use high temperature function to master all kinds of refractory material function, especially high temperature use function. Selection should give full play to its advantages, and from the furnace structure, masonry and protection to overcome its shortcomings.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- Do not know where the coking plant do dust treatment, processing conditions are different, the dust collector is not the same

- Q: Ask for help about the phase of refractory material

- Binding phase. The binding phase is the phase outside the main crystal phase or the main crystal phase and the sub crystalline phase. The binding phase can be made up of either a fine crystal or a glass phase or a composite of the two. Such as the combination of magnesia brick, magnesia chrome brick, magnesia brick and other basic refractories in phase is composed of crystal matrix; silica brick, clay brick is made of glass phase in the form. When the matrix is formed at high temperature, the liquid phase is low, and the viscosity of the liquid phase is low and the quantity is large, the production and properties of refractory products are essentially controlled by the substrate.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

Send your message to us

Corundum Mullite Bricks for Refractory Applications

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords