High Alumina Corundum Mullite Bricks with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

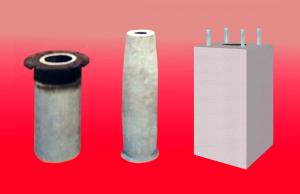

Corundum Mullite Bricks

Al2O3, %: 88-85

Fe2O3, %: 1.0-1.2

Refractoriness, o C: 1790

Bulk Density: 3.0min

AP, %: 16max

CCS, MPa: 120-80

The product is composed of high quality mullite and high purity fused corundum as raw materials with addition of specified binder by shaping at high pressure and sintering at high temperature. With features of high refractoriness under load, compact structure, low porosity and high resistance to corrosion, the products are available for the furnace bottom, ceramic cup bottom lining and combined masonry of tuyere, taphole and slag notch of large-sized BF.

1. Good thermal shock

2. High temperature resistance

3. Used in furnace

4. Good quality, QARefractory corundum mullite ceramic brick Corundum ceramic brick mullite ceramic plate, corundum ceramics, refractory ceramic brick Alumina Ceramic Plate or Sheet, High Alumina PlateMaterial: High alumina or Corundum Mullite

Item Corundum Mullite Brick

Max. Service temperature (° c) 1750

Bulk Density (g/cm3) 2.2~2.9

Reheat Linear Change(° c× 4h) ≤ % 0.2(1600× 4h)

Compressive Strength (Mpa) 30-80

Apparent Porosity≤ % 18~25

AL2O3(%)≥ 80-90

SiO2(%) 8-18

Fe2O3(%)≤ 0.2

- Q: What is fireproof concrete?

- A series of concrete with fire resistance and heat resistance is made of Portland cement series as cementing material and heat-resistant material as aggregate. Silicate fireproof heat-resistant concrete with Portland slag cement, Portland cement and water glass as cementing material, broken clay brick, clay, cement clinker, broken high alumina brick as aggregate.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- Therefore, the choice and masonry of refractory bricks are of vital importance. If there is a brick kiln kiln off block process of reproduction, is now because of the use of refractory brick kiln material mostly three grade high alumina bricks. The content of AL2O3 is about 55%, of which the content of Fe2O3 is about 2%, which is weak, and the alkali corrosion resistance is a little worse. In a containing three grade high alumina bricks in the composition of AL2O3, Si2O3, and other elements also contain K, Na trace, were the most, thus causing the system of the low melting point is very low, even at 1400 DEG C has been liquid phase, and generate CaAL12O19 limestone and calcium feldspar etc.. Form corrosion loss. Therefore, a long time will cause the loss of block. On the one hand, it may be caused by construction.

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: What is the standard size of high alumina brick?

- The country has laid down a number of criteria for the use of refractory bricks to unify market demand.

- Q: How many cubic bricks does a high alumina brick have?

- It is related to the content of aluminum in high alumina bricks.

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- Refractory powders are not rich in free silica in varying degrees

- Q: Can high alumina brick resist carburizing?

- It is heavy brick mullite brick, brick to do the heavy weight to more than 2.4 manufacturers can achieve a few feeling

- Q: Corundum, high alumina and fireclay refractory difference is what

- Corundum is unknown. The high alumina brick has higher aluminum content than the clay brick, and the temperature resistance is higher than 300 degrees. It is more durable and durable than the clay brick. The production process of high alumina brick is better than that of clay brick. For example, the weight of good clay brick is 3.7kg, and that of high alumina is 4.2kg. Good density. But the price of high aluminum is too high: ordinary clay brick (standard brick example) in 1.1--2.5 yuan / block, high aluminum to 4.5 yuan / block, or even more expensive. The extra high aluminum has reached 5000 tons. Say straight white point is: under the same conditions, clay brick for a period of one year, then the high aluminum for more than three years.

- Q: What is spalling resistant high alumina brick?

- Using bauxite as main raw materials, the introduction of a small amount of ZrO2 (ZrO2 is due to phase transition, between monoclinic and tetragonal type can improve the thermal stability of the products), adding a certain amount of binder and additives, the particle size distribution control mud, forming and sintering of refractory products produced, called anti stripping high alumina brick.

- Q: How are the grades of high alumina bricks differentiated?

- If the content of Al2O3 is higher than 90%, it is called corundum brick. Because of the different resources, the standards of different countries are not exactly the sameFor example, European countries limit the content of Al2O3 for high alumina refractory materials at 42%.

Send your message to us

High Alumina Corundum Mullite Bricks with Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords