CorrugatedStainless Steel Sheet with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321/410/420/430/444/443/409L,and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

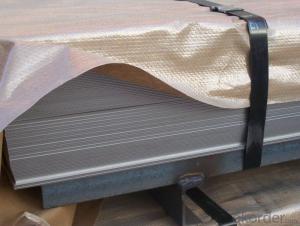

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

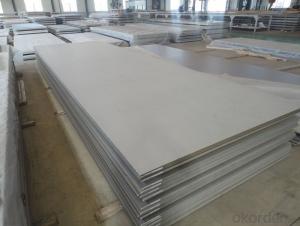

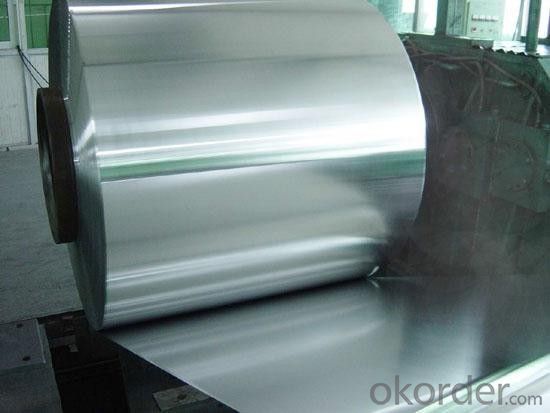

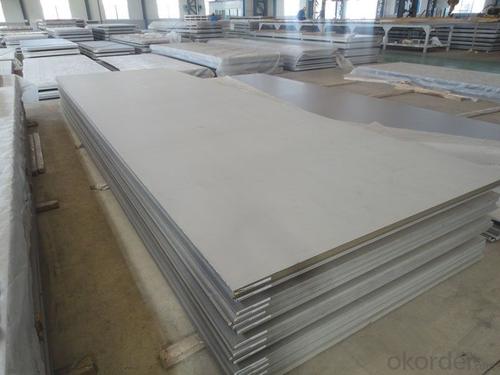

Product Details:

Cold Rolled and Hot Rolled:

Packing and Loading:

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours

If you have any question about stainless steel sheets, do not forget to send the email to us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: The difference between 304J1 stainless steel plate and 304 stainless steel plate

- The price is lower, the deep processing performance is better.304J1 stainless steel is a copper containing material of 304 stainless steel. It is mainly used for deep processing, and also belongs to the series of nickel. By the Japanese on the basis of the successful development of American Standard 304.

- Q: What are the different types of stainless steel sheet finishes for decorative purposes?

- There are several different types of stainless steel sheet finishes that are commonly used for decorative purposes. These finishes are achieved by various surface treatments and processes, each resulting in a unique appearance and texture. Some of the most popular finishes include: 1. No. 4 finish: Also known as brushed or satin finish, it is achieved by applying a series of abrasive belts to the surface, resulting in a smooth, satin-like appearance. This finish is commonly used in architectural and decorative applications. 2. No. 8 mirror finish: This finish is achieved by polishing the surface to a highly reflective mirror-like appearance. It is often used in applications where aesthetic appeal is important, such as wall cladding, signage, and decorative elements. 3. Hairline finish: This finish features a fine, directional grain pattern created by polishing the surface with fine abrasive belts. It provides a subtle and elegant look, commonly used in interior design applications like elevators, appliances, and furniture. 4. Embossed finish: In this finish, the stainless steel sheet is pressed with a pattern or texture, creating a three-dimensional surface. This finish is often used in architectural applications, such as wall panels, ceiling tiles, and decorative trim. 5. Bead blasted finish: This finish is achieved by blasting the surface with fine glass beads under high pressure, resulting in a uniform, matte appearance. It provides a unique texture and is commonly used in applications where a non-reflective surface is desired, such as countertops, kitchen appliances, and signage. 6. Colored finishes: Stainless steel sheets can also be coated with various colors through processes like PVD (Physical Vapor Deposition) or powder coating. These finishes provide a wide range of color options, allowing for more design flexibility in decorative applications. Overall, the choice of stainless steel sheet finish for decorative purposes depends on the desired aesthetic, functionality, and application requirements. Each finish offers its own unique look and feel, allowing for versatile design possibilities in various industries.

- Q: What are the advantages of using stainless steel sheets?

- There are several advantages of using stainless steel sheets. Firstly, stainless steel is highly resistant to corrosion, making it suitable for various applications in industries such as construction, automotive, and food processing. Secondly, stainless steel sheets are known for their durability and strength, making them ideal for withstanding heavy loads and extreme temperatures. Additionally, stainless steel sheets are easy to clean, maintain, and sanitize, making them a hygienic choice for applications in healthcare and food industries. Lastly, stainless steel sheets offer an aesthetically pleasing appearance, making them a popular choice for architectural and decorative purposes.

- Q: Can stainless steel sheets be used in industrial applications?

- Yes, stainless steel sheets can definitely be used in a wide range of industrial applications. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it ideal for various industrial environments. It is commonly used in sectors such as automotive, aerospace, construction, manufacturing, food and beverage, chemical processing, and many others. Stainless steel sheets are often used for their ability to withstand high temperatures, harsh chemicals, and extreme conditions. They can be fabricated into different shapes and sizes, making them suitable for a wide range of applications. Stainless steel sheets are commonly used for manufacturing equipment and machinery, storage tanks, pipelines, architectural structures, and as a protective layer on surfaces that require resistance to corrosion. Furthermore, stainless steel sheets offer hygienic properties, making them suitable for applications in the food and beverage industry. They are easy to clean, maintain, and sterilize, ensuring compliance with strict industry standards. In summary, stainless steel sheets are versatile and reliable materials that can be effectively used in various industrial applications due to their exceptional corrosion resistance, durability, strength, and hygienic properties.

- Q: Can stainless steel sheets be used for exterior cladding?

- Indeed, exterior cladding can utilize stainless steel sheets. The robustness and resistance to corrosion of stainless steel make it appropriate for various purposes, including cladding. Stainless steel sheets present exceptional endurance against weathering, UV rays, and extreme temperatures, rendering them perfect for external usage. They can endure severe environmental conditions, such as heavy rain, snow, and strong winds, without deteriorating or losing their aesthetic charm. Moreover, stainless steel sheets are available in an extensive array of finishes, allowing for customization and design adaptability. Whether for residential, commercial, or industrial edifices, stainless steel cladding offers a durable and visually pleasing solution.

- Q: 420 stainless steel, there is no good 304

- 420 and 304 is not the same type of stainless steel, is 420 stainless iron, nickel containing little, 420 series stainless steel cutter belongs to the material processing of finished products and then quenching hardness is high, the 304 is rust resistant stainless steel material, widely used, the price is slightly more expensive than the 420, at about 20 yuan a kilogram.

- Q: What are the different types of perforated patterns available for stainless steel sheets?

- There are several different types of perforated patterns available for stainless steel sheets, each designed to serve specific purposes and meet different aesthetic preferences. Some of the commonly used patterns include: 1. Round Hole Pattern: This is the most basic and widely used perforated pattern. It consists of evenly spaced round holes across the sheet, allowing for excellent airflow and drainage. It is commonly used in industrial applications such as filtration systems or as decorative panels. 2. Square Hole Pattern: Similar to the round hole pattern, the square hole pattern offers a more geometric and uniform appearance. It is often preferred for architectural and decorative purposes, as it provides a modern and sleek look. 3. Slotted Hole Pattern: Slotted holes are elongated and rectangular in shape, providing more flexibility in terms of airflow and visibility. They are often used in applications that require better drainage or where a higher open area is needed, such as in grills or air ventilation systems. 4. Hexagonal Hole Pattern: Hexagonal holes offer a unique and visually appealing pattern. They provide excellent strength and structural integrity, making them suitable for applications that require durability, such as safety barriers or machine guards. 5. Decorative Hole Pattern: Apart from the standard perforated patterns, there are also various decorative hole patterns available for stainless steel sheets. These patterns usually feature intricate designs or shapes, adding an artistic touch to architectural and interior design applications. It is important to consider the specific requirements of your project, such as airflow, visibility, drainage, or aesthetic appeal, when selecting the appropriate perforated pattern for stainless steel sheets. Consulting with a supplier or expert in the field can help you make an informed decision based on your needs.

- Q: What are the different types of edge finishes for stainless steel sheets?

- There are several different types of edge finishes that can be applied to stainless steel sheets. These finishes are designed to enhance the appearance and functionality of the edges while also providing protection against corrosion and damage. 1. Mill Finish: This is the most basic type of edge finish, where the edges are left as they come from the mill. It is a straight, unfinished edge without any additional treatment or polishing. 2. Deburred Edge: In this type of finish, the rough edges are smoothed out and deburred using abrasive materials. This helps to eliminate sharp edges and burrs, making the sheet safer to handle and preventing potential injuries. 3. Rounded Edge: A rounded edge finish involves milling or machining the edges to create a curved or rounded profile. This type of finish is commonly used in applications where safety is a concern, as it reduces the risk of cuts or injuries caused by sharp edges. 4. Beveled Edge: A beveled edge finish involves cutting or grinding the edges at an angle to create a sloped or chamfered profile. This type of finish is often used for aesthetic purposes, as it adds a decorative element to the sheet and can create a smooth transition between different surfaces. 5. Polished Edge: In this type of finish, the edges of the stainless steel sheet are polished to a high shine using abrasive materials or polishing compounds. This produces a smooth, reflective surface that enhances the overall appearance of the sheet and gives it a more finished look. 6. Brushed Edge: A brushed edge finish involves applying a brushed texture to the edges of the stainless steel sheet. This is achieved by using abrasive materials or brushes to create a consistent pattern of fine lines or scratches. The brushed edge finish can provide a unique and contemporary look to the sheet. These different types of edge finishes for stainless steel sheets offer various benefits and can be chosen based on the specific requirements of the application. Whether it's for safety, aesthetics, or functionality, selecting the right edge finish can greatly enhance the performance and visual appeal of stainless steel sheets.

- Q: Are stainless steel sheets suitable for cryogenic storage containers?

- Indeed, cryogenic storage containers are well-suited for stainless steel sheets. Renowned for its outstanding qualities at low temperatures, stainless steel proves to be an optimal option for cryogenic purposes. Its remarkable resistance to thermal expansion and contraction minimizes the risk of cracking or leaking even in extremely low temperatures. Moreover, stainless steel boasts exceptional durability and corrosion resistance, enabling it to endure the harsh conditions of cryogenic storage and guarantee the safety and integrity of stored materials. Consequently, stainless steel sheets find extensive application in the creation of cryogenic storage containers across diverse industries, including pharmaceuticals, aerospace, and scientific research.

Send your message to us

CorrugatedStainless Steel Sheet with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords