Stainless Steel Sheet Manufacturer with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321/410/420/430/444/443/409L,and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

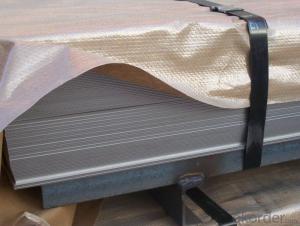

Packing and Loading:

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours

If you have any question about stainless steel sheets, do not forget to send the email to us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for automotive applications?

- Yes, stainless steel sheets are suitable for automotive applications. Stainless steel is known for its durability, strength, and corrosion resistance, making it an ideal material for various automotive components. It is commonly used for body panels, exhaust systems, trim, and other parts that require resistance to weathering, heat, and chemical exposure. Stainless steel sheets offer excellent aesthetic appeal, as they can be polished to a mirror-like finish or brushed to create a sleek and modern appearance. Additionally, stainless steel is easily formable, allowing for the creation of complex shapes and designs required in automotive manufacturing. Overall, stainless steel sheets provide the necessary properties and versatility to meet the demanding requirements of automotive applications.

- Q: Are stainless steel sheets resistant to pitting corrosion?

- Yes, stainless steel sheets are resistant to pitting corrosion. Pitting corrosion is a localized form of corrosion that occurs in specific areas, resulting in small pits or holes on the metal surface. Stainless steel sheets are made with a high percentage of chromium, which forms a passive oxide layer on the surface, providing excellent resistance to corrosion. This oxide layer acts as a barrier, protecting the metal from pitting corrosion. Additionally, stainless steel contains other alloying elements such as nickel and molybdenum, which further enhance its resistance to pitting corrosion. Therefore, stainless steel sheets are highly resistant to pitting corrosion and are commonly used in applications where corrosion resistance is crucial, such as in the construction, automotive, and food processing industries.

- Q: What is the ductility of stainless steel sheets?

- Stainless steel sheets possess a remarkable quality known as ductility. This quality enables them to endure tensile stress without succumbing to fractures or breaks. The stainless steel material is renowned for its outstanding ductility, which grants it the ability to withstand stretching, bending, or hammering without compromising its structural integrity. This exceptional attribute endows stainless steel sheets with great versatility, rendering them suitable for an extensive array of applications such as construction, automotive manufacturing, and kitchen appliances. The high ductility of stainless steel empowers it to be effortlessly molded into intricate shapes or rolled into thin sheets, making it an ideal choice for delicate designs or structures with thin walls. Moreover, the ductility of stainless steel also facilitates easy welding, solidifying its status as a favored option for fabrication processes.

- Q: What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets depend on several factors such as the grade of stainless steel, thickness of the sheet, and the specific type of bending process being used. Stainless steel sheets are known for their excellent strength and durability, which allows them to be bent to a certain extent without breaking or cracking. In general, stainless steel sheets can be bent to a radius that is at least twice the thickness of the sheet. For example, if the sheet is 1mm thick, it can typically be bent to a minimum radius of 2mm. However, it is important to note that this is just a general guideline and the actual bending limits may vary depending on the specific grade of stainless steel. Certain grades of stainless steel, such as 304 and 316, have higher yield strengths and are more resistant to deformation, making them suitable for more severe bending applications. Thicker sheets also have higher bending limits compared to thinner ones, as they have more material to withstand the bending forces. It is also worth mentioning that the type of bending process used can affect the bending limits of stainless steel sheets. Processes like press brake bending and roll bending are commonly used for bending stainless steel sheets. These processes utilize different techniques and equipment, which can result in varying bending limits. To determine the exact bending limits for a specific grade and thickness of stainless steel sheet, it is best to consult the manufacturer's specifications or seek guidance from a professional metal fabricator. They can provide accurate information and guidance on the bending capabilities of stainless steel sheets for your specific application.

- Q: What are the different types of colored finishes available for stainless steel sheets?

- There are several different types of colored finishes available for stainless steel sheets. These finishes are designed to enhance the appearance of stainless steel and provide various aesthetic options. Some of the most common colored finishes include: 1. Mirror Finish: This finish is highly reflective and creates a mirror-like surface on stainless steel sheets. It is achieved by polishing the stainless steel surface to a high gloss. Mirror finishes are commonly used in decorative applications and provide a sleek and modern look. 2. Satin Finish: Also known as brushed or matte finish, this type of finish has a smooth, non-reflective surface. It is achieved by brushing the stainless steel surface with an abrasive material. Satin finishes are commonly used in architectural and industrial applications and provide a clean and contemporary appearance. 3. Colored Powder Coating: Powder coating involves applying a dry powder to the stainless steel surface and then curing it under heat. This process creates a durable and uniform colored finish. Colored powder coatings are available in a wide range of hues, allowing for customization and versatility in design. 4. PVD Coating: Physical Vapor Deposition (PVD) is a process that involves depositing a thin layer of metal onto the stainless steel surface. This coating can be in various colors, such as gold, bronze, black, or rose gold. PVD coatings provide excellent durability and resistance to wear, making them suitable for high-traffic areas or decorative applications. 5. Colored Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the stainless steel surface. By using dyes during the anodizing process, a wide range of colors can be achieved. Colored anodized finishes are known for their corrosion resistance and can be utilized in architectural or design-oriented applications. Each of these colored finishes offers unique characteristics and can be chosen based on the desired aesthetic, durability, and specific application requirements. It is important to consider factors such as the level of maintenance needed, environmental conditions, and the intended use of the stainless steel sheets when selecting a colored finish.

- Q: Are stainless steel sheets suitable for high-temperature applications?

- Yes, stainless steel sheets are suitable for high-temperature applications. They have excellent heat resistance properties and can withstand elevated temperatures without losing their strength or structural integrity.

- Q: Can stainless steel sheets be used for food packaging or containers?

- Yes, stainless steel sheets can be used for food packaging or containers. Stainless steel is a safe and hygienic material that is resistant to corrosion, heat, and chemical reactions, making it ideal for storing and transporting food items. Additionally, its durability and easy cleaning properties make it suitable for repeated use in the food industry.

- Q: Can stainless steel sheets be used for food storage containers?

- Yes, stainless steel sheets can be used for food storage containers. Stainless steel is a popular choice for food storage containers due to its durability, non-reactive nature, and resistance to corrosion. It does not impart any taste or odor to the stored food, making it safe for long-term storage. Stainless steel is also easy to clean and maintain, making it a hygienic option for food storage. Additionally, stainless steel containers are often preferred for their eco-friendly properties, as they are reusable and can help reduce the use of single-use plastic containers. Overall, stainless steel sheets are a suitable and reliable choice for food storage containers.

- Q: Can stainless steel sheets be used for medical implant devices?

- Medical implant devices can utilize stainless steel sheets, as they possess excellent mechanical properties, corrosion resistance, and biocompatibility. Stainless steel is widely employed in the medical field due to its strength, durability, and ability to endure sterilization processes. Various medical implant devices, including plates, screws, and pins used in orthopedic surgeries, dental implants, cardiovascular devices, and other procedures, can be fabricated from stainless steel sheets. The high strength-to-weight ratio of stainless steel makes it suitable for applications requiring load-bearing capabilities, while its resistance to corrosion ensures longevity within the body. Moreover, stainless steel is a biocompatible material, meaning it is well-tolerated by the human body and does not cause adverse reactions or allergies. Techniques like passivation or coating can enhance the biocompatibility of stainless steel surfaces. It is vital to emphasize that selecting the appropriate stainless steel grade and surface finish is essential for medical implant devices to ensure compatibility with specific body tissues and environments. Thorough testing and regulatory approval are also necessary to guarantee the safety and effectiveness of stainless steel medical implant devices. To summarize, stainless steel sheets can indeed be utilized for medical implant devices due to their mechanical properties, corrosion resistance, and biocompatibility. Ensuring the suitability and safety of stainless steel implants in medical applications necessitates proper selection, testing, and regulatory approval.

- Q: Are stainless steel sheets suitable for medical applications?

- Yes, stainless steel sheets are suitable for medical applications. Stainless steel is a popular choice in the medical field due to its excellent corrosion resistance, durability, and ease of sterilization. It is commonly used in medical equipment, surgical instruments, implants, and even architectural applications within healthcare facilities. Stainless steel is highly resistant to staining, bacterial growth, and contamination, making it a hygienic and safe material for medical use. Additionally, its strength and low maintenance requirements make it suitable for long-term use in demanding medical environments. Overall, stainless steel sheets meet the stringent requirements of medical applications and are a reliable choice for healthcare professionals.

Send your message to us

Stainless Steel Sheet Manufacturer with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords