Concrete Pump Truck Parts Elbow Bend R275 DN112 157Flange 90DGR Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. Adopt the new plasma quenching and chromium plating process, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.

2. Service life: 55000-150000 CBM Concrete. The inner side of this concrete pump elbow undergoes heat treatment, and then the hardness can reach 68HRC.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market.

5. We can supply OEM service and can also produce according to your requirements.

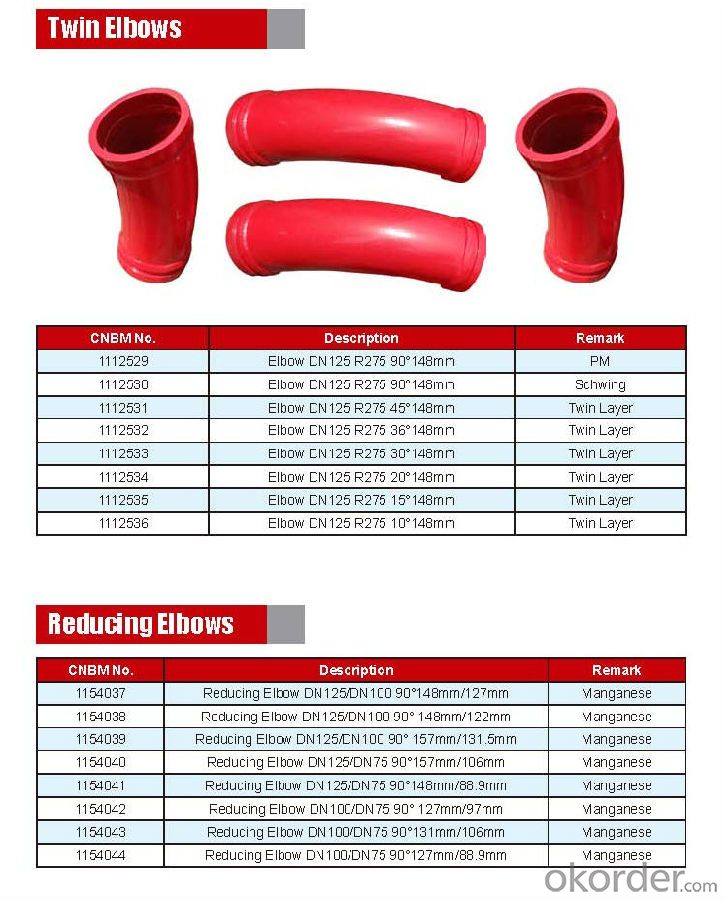

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

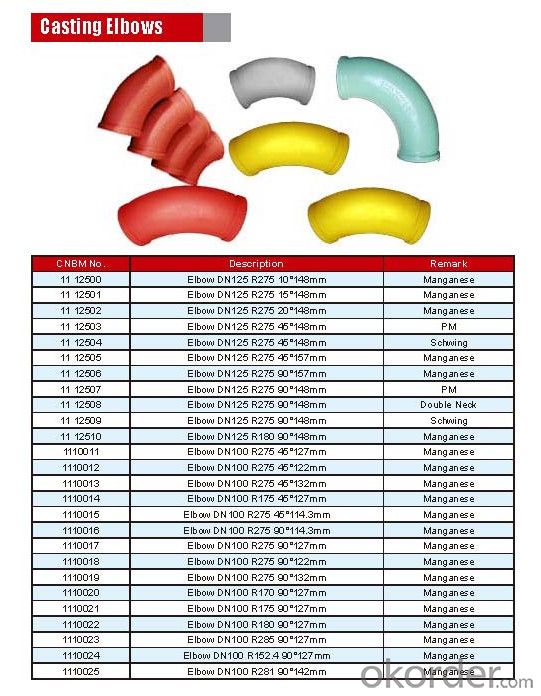

Product Specifications:

Technology: Cast

Dimension: DN112

Radius: 180mm

Degree: 90D

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: What are the different types of concrete pump wear rings?

- There are primarily two types of concrete pump wear rings: stationary wear rings and rotating wear rings. Stationary wear rings are fixed in position and provide a surface for the rotating wear ring to slide against. Rotating wear rings, on the other hand, are designed to spin with the impeller and prevent direct contact between the impeller and stationary wear ring, reducing friction and extending the life of the pump.

- Q: What are the potential risks of using non-standard or modified hydraulic components in concrete pump spare parts?

- Using non-standard or modified hydraulic components in concrete pump spare parts can pose several potential risks. Firstly, non-standard components may not have undergone the same rigorous testing and quality control as the original equipment manufacturer (OEM) parts. This means that their performance and durability may be compromised, leading to potential failures or malfunctions. Such failures can result in accidents, injuries, or damage to the equipment or surrounding structures. Secondly, using non-standard or modified components may void the warranty of the concrete pump and its spare parts. Manufacturers typically offer warranties to ensure the reliability and safety of their products. By using non-standard components, the warranty may become null and void, leaving the user responsible for any repairs or replacements needed due to issues arising from these non-standard parts. Another risk is the potential compatibility issues that may arise when using non-standard or modified components. Hydraulic systems rely on precise engineering and compatibility between various components to function optimally. Non-standard or modified parts may not fit properly or may have different specifications, leading to leaks, pressure imbalances, or reduced overall performance. Furthermore, the use of non-standard or modified components may also impact the overall efficiency and productivity of the concrete pump. OEM parts are designed to work seamlessly with the rest of the system, ensuring smooth operation and maximum output. By using non-standard parts, the performance of the pump may be compromised, resulting in increased downtime, decreased productivity, and higher maintenance costs. Lastly, the use of non-standard or modified components may also have legal and regulatory implications. In some jurisdictions, there may be regulations or standards in place that require the use of OEM or certified parts for certain equipment, including concrete pumps. Failure to comply with these regulations can result in fines, penalties, or legal liabilities in case of accidents or failures. In conclusion, the potential risks of using non-standard or modified hydraulic components in concrete pump spare parts include compromised performance and durability, warranty voidance, compatibility issues, reduced efficiency, and legal and regulatory implications. It is always advisable to use OEM or certified spare parts to ensure the safety, reliability, and optimal performance of the equipment.

- Q: How often should a concrete pump cleaning ball be used?

- A concrete pump cleaning ball should be used after every pumping job or at least once a day to ensure the cleanliness and proper functioning of the pump. The cleaning ball helps remove any build-up or debris that may have accumulated inside the pump and its pipes during the pumping process. Regular use of a cleaning ball helps prevent clogs and blockages, ensuring a smooth and efficient pumping operation.

- Q: How often should hopper agitator shaft seals be replaced in a concrete pump?

- The frequency at which hopper agitator shaft seals should be replaced in a concrete pump depends on several factors such as the type of pump, the amount of usage, the operating conditions, and the maintenance practices followed. Generally, hopper agitator shaft seals should be inspected regularly for signs of wear, damage, or leakage. If any issues are detected, they should be addressed promptly to prevent further damage. However, as a rough guideline, these seals may need to be replaced every 6 to 12 months or after approximately 500 to 1,000 operating hours. It is important to note that this is just an estimate, and the actual replacement frequency may vary. Factors such as the quality of the seals, the intensity of usage, and the conditions in which the pump operates can significantly influence the lifespan of the seals. Additionally, regular maintenance and proper lubrication can help extend the longevity of the seals. To ensure optimal performance and prevent potential issues, it is advisable to consult the manufacturer's recommendations and guidelines specific to the concrete pump model being used. Following their guidelines and regularly inspecting the seals will help determine the appropriate replacement interval for the hopper agitator shaft seals and ensure the pump operates efficiently.

- Q: What are the different types of concrete pump hopper cylinders seals?

- Concrete pump hopper cylinder seals come in various types, each catering to specific needs and requirements. The most commonly used types are as follows: 1. Piston seals: These seals prevent leakage between the piston and cylinder bore. They are typically crafted from durable materials like rubber or polyurethane, ensuring resistance to wear and tear. 2. Rod seals: Installed on the piston rod, rod seals prevent leakage between the rod and cylinder head. They are commonly made of rubber or fabric-reinforced rubber, delivering reliable sealing even in high-pressure conditions. 3. Wiper seals: These seals are utilized to remove dirt, dust, and other contaminants from the retracting piston rod. They are usually composed of polyurethane or rubber, effectively sealing and protecting the cylinder. 4. Wear rings: Employed to decrease friction and prevent metal-to-metal contact between the piston and cylinder bore, wear rings are usually made of materials like bronze or Teflon. They significantly extend the cylinder's lifespan by reducing wear and tear. 5. Backup rings: These rings provide additional support and stability when used alongside other seals. Typically crafted from materials like rubber or PTFE, backup rings prevent extrusion and damage to the primary seal. In summary, the choice of the appropriate concrete pump hopper cylinder seal relies on factors such as the specific application, operating conditions, and desired performance characteristics. It is crucial to select seals that are compatible with the material being pumped, offer effective sealing, and have a long lifespan to ensure optimal performance and minimize maintenance needs.

- Q: What is the purpose of a concrete pump remote control battery?

- The purpose of a concrete pump remote control battery is to provide power for the remote control device, allowing operators to remotely control the concrete pump's functions and movements without being physically connected to the machine.

- Q: How often should concrete pump hydraulic motors be inspected and replaced?

- The inspection and replacement frequency of concrete pump hydraulic motors varies depending on several factors, including usage intensity, maintenance practices, and the specific guidelines of the manufacturer. However, as a general guideline, it is advisable to inspect hydraulic motors every 6 to 12 months. During this inspection, it is important to check for signs of wear and tear, leaks, and any abnormal noises that may occur during operation. Additionally, regular maintenance tasks like lubrication and cleaning should be carried out according to the manufacturer's recommendations. Ultimately, the decision to replace hydraulic motors should be based on their overall condition and performance. If noticeable issues or a significant decrease in efficiency are observed, it may be necessary to replace the hydraulic motors before the suggested inspection interval.

- Q: How often should concrete pump filters be inspected and replaced?

- Regular inspections of concrete pump filters are recommended, ideally once a week. The replacement frequency will vary based on factors such as pump type, concrete quality, and working conditions. Typically, clogged or inefficient filters should be replaced. This can happen every few weeks to a few months. It is essential to keep filters clean and functional to avoid blockages, improve pump performance, and prolong equipment lifespan.

- Q: How often should hopper grate handles be inspected or replaced in a concrete pump?

- Regular inspections should be conducted on hopper grate handles in a concrete pump to identify any signs of wear and tear or damage. The frequency of these inspections and the need for replacement may vary depending on the equipment's usage and condition. It is suggested that the hopper grate handles be inspected at least once a month or after every 500 hours of operation, whichever occurs first. During the inspection, it is important to verify that the handles are firmly attached to the hopper grate and to examine them for any cracks, bends, or other structural problems. If any damage is detected, it is recommended to promptly replace the handles to prevent accidents or further harm to the equipment. It is also crucial to adhere to the manufacturer's guidelines and recommendations for the maintenance and replacement of hopper grate handles. By regularly inspecting and replacing the handles as necessary, the safe and efficient operation of the concrete pump can be ensured.

- Q: Can concrete pump spare parts be tested for compatibility with different types of concrete mixes?

- Testing for compatibility with different types of concrete mixes is crucial for concrete pump spare parts. These spare parts, including pipes, hoses, and valves, are specifically designed to handle distinct pressures, flow rates, and concrete mix types. To determine compatibility, the spare parts undergo testing with various concrete mix compositions, which encompass diverse aggregate sizes, cement types, and admixtures. This testing procedure assesses the spare parts' ability to withstand the unique characteristics and properties of different concrete mixes. The compatibility testing process evaluates factors such as durability, resistance to abrasion and corrosion, and the capacity to meet specific pumping requirements for various concrete mixes. This testing can be carried out either in laboratory settings or on-site, depending on the project's specific needs. By conducting compatibility testing on concrete pump spare parts, potential issues like clogging, wear and tear, or reduced performance can be identified and resolved in advance. This ensures smoother and more efficient concrete pumping operations, reducing downtime and enhancing overall productivity. It is important to note that manufacturers of concrete pump spare parts often provide technical specifications and guidelines for their products, including information on compatibility with different concrete mix types. Adhering to these guidelines and performing compatibility testing aids in achieving optimal performance and longevity of the spare parts, resulting in successful concrete pumping operations.

Send your message to us

Concrete Pump Truck Parts Elbow Bend R275 DN112 157Flange 90DGR Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords