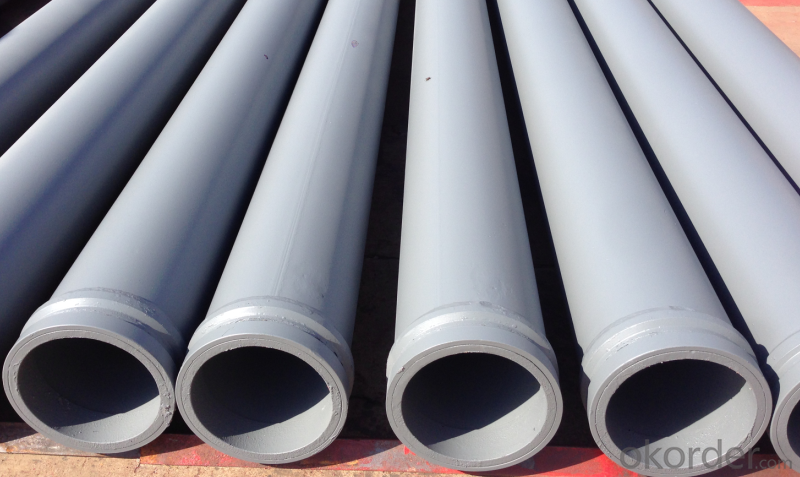

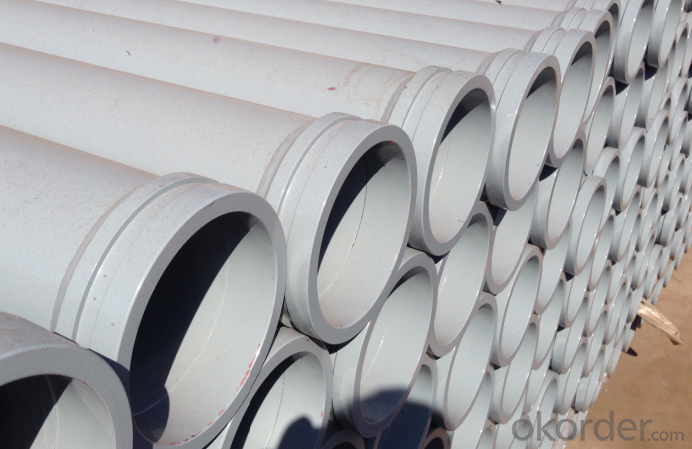

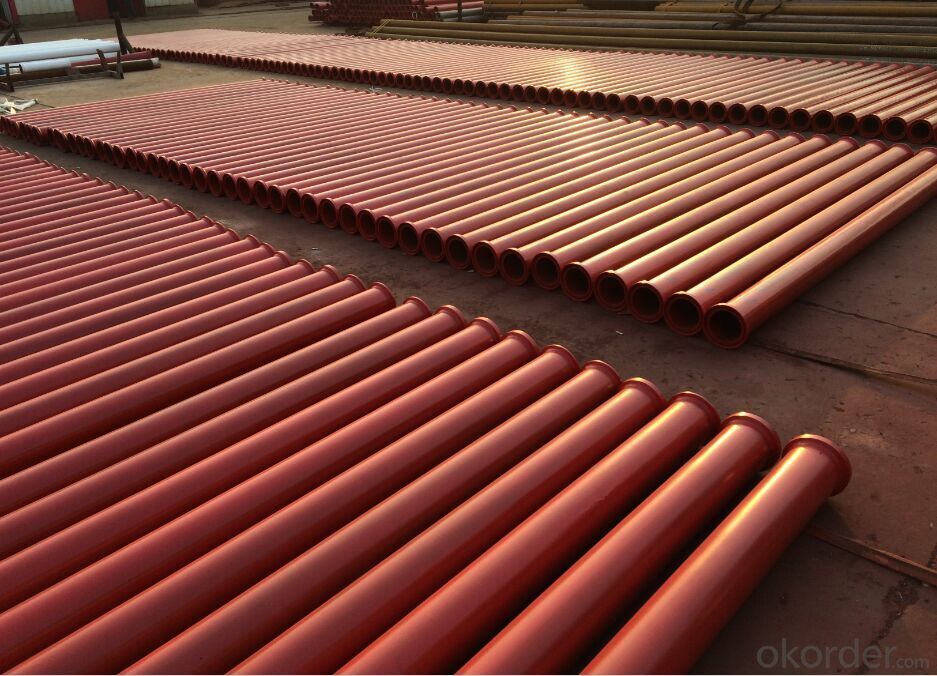

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 2MTR Thick 3.2MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.

2. Uniform baking finish.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. A wide range of specifications for you.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 2m

Thickness: 3.2mm

Material: ST52

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: How often should hopper agitator shaft seals be replaced in a concrete pump?

- The replacement frequency of hopper agitator shaft seals in a concrete pump relies on various factors such as pump type, usage amount, operating conditions, and maintenance practices implemented. In general, it is recommended to regularly inspect hopper agitator shaft seals for any signs of wear, damage, or leakage. If any problems are detected, they should be promptly addressed to prevent further harm. However, as a rough estimate, these seals may require replacement every 6 to 12 months or after approximately 500 to 1,000 operating hours. It is important to understand that this is merely an approximation, and the actual replacement frequency may differ. The quality of the seals, intensity of usage, and operating conditions of the pump can significantly impact the lifespan of the seals. Furthermore, regular maintenance and appropriate lubrication can aid in extending the durability of the seals. To ensure optimal performance and prevent potential issues, it is advisable to consult the manufacturer's recommendations and guidelines specific to the concrete pump model being utilized. Adhering to their guidelines and conducting regular inspections of the seals will aid in determining the appropriate replacement interval for the hopper agitator shaft seals and guarantee efficient pump operation.

- Q: Can concrete pump spare parts be coated with UV-resistant coatings for outdoor applications?

- Concrete pump spare parts can benefit from the application of UV-resistant coatings to protect them from the damaging effects of UV radiation. These coatings are specially designed to prevent fading, cracking, and deterioration over time. By coating the spare parts, they are shielded from prolonged exposure to sunlight and other environmental factors, thus extending their lifespan and ensuring optimal performance outdoors. Furthermore, these coatings offer additional protection against weathering, including moisture, temperature fluctuations, and chemical exposure. As a result, it is highly recommended to coat concrete pump spare parts with UV-resistant coatings in order to enhance their durability and maintain their functionality when used outside.

- Q: What is the role of a concrete pump seal?

- The role of a concrete pump seal is to prevent leakage of concrete or other fluids from the pump system, ensuring that the pump operates efficiently and effectively.

- Q: What are the advantages of using polyurethane components in concrete pump spare parts?

- There are several advantages of using polyurethane components in concrete pump spare parts. Firstly, polyurethane is highly durable and resistant to wear and tear, ensuring longer lifespan and reduced maintenance costs. Secondly, polyurethane has excellent abrasion resistance, which allows it to withstand the harsh conditions and high pressures involved in concrete pumping. Additionally, polyurethane components offer superior flexibility, allowing for easier installation and reduced risk of breakage. Lastly, polyurethane is known for its chemical resistance, ensuring that the spare parts can withstand exposure to various chemicals and substances commonly found in concrete. Overall, using polyurethane components in concrete pump spare parts provides enhanced durability, flexibility, and resistance to abrasion, making it a preferred choice in the construction industry.

- Q: How often should concrete pump lubrication systems be inspected and maintained?

- Concrete pump lubrication systems should be inspected and maintained regularly, ideally on a monthly basis.

- Q: What is the first generation pumping technology of concrete pump?

- The machine assembly is simple and the production cost is low, but the electrical control is complex

- Q: How much do concrete pump spare parts typically cost?

- The cost of concrete pump spare parts can vary significantly depending on the specific part needed, its brand, quality, and availability. It is recommended to contact suppliers or manufacturers for accurate and up-to-date pricing information.

- Q: How does the concrete pump work?

- After position, the pump shall show stop light to avoid collision

- Q: What is the purpose of a concrete pump piston?

- The purpose of a concrete pump piston is to pressurize and push the concrete mixture through a pipeline, enabling efficient and accurate placement of the concrete in construction projects.

- Q: How often should hopper grate pins be inspected or replaced in a concrete pump?

- To maintain proper functioning and prevent potential problems, it is important to regularly inspect the hopper grate pins in a concrete pump. A suggested guideline is to inspect these pins at least once a month or after every 200 hours of operation, whichever comes first. However, the inspection frequency may vary based on the specific conditions and usage of the concrete pump. During the inspection, it is crucial to examine the hopper grate pins for any signs of wear, damage, or deformities. If any issues are discovered, they should be promptly addressed to prevent further damage and ensure the safe and efficient operation of the concrete pump. When significant signs of wear or damage are observed in the hopper grate pins, it is necessary to replace them immediately to maintain their functionality. It is important to follow the manufacturer's guidelines and recommendations for replacing these pins, as they may differ depending on the specific model and design of the concrete pump. By conducting regular inspections and replacing hopper grate pins in a timely manner, the longevity and reliability of the concrete pump can be enhanced, reducing the risk of unexpected breakdowns and ensuring optimal performance.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 2MTR Thick 3.2MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords