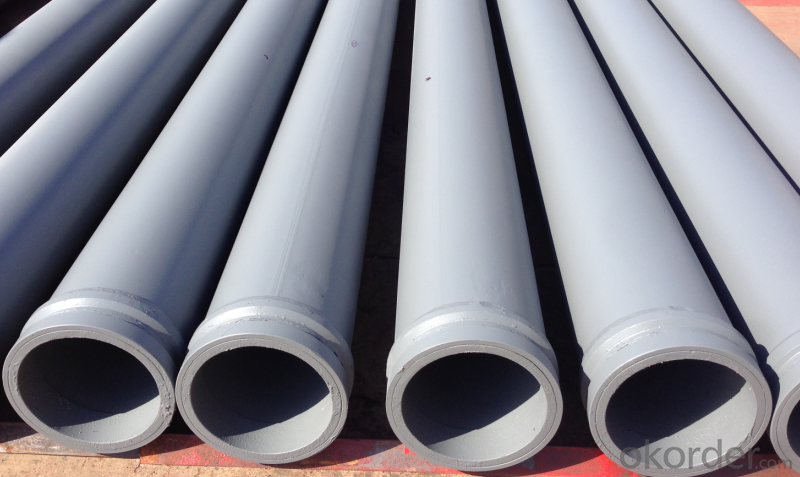

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 3MTR Thick 4.5MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

Adopt ST52 as standard material, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.

The inner side of this concrete pump pipe can undergoes heat treatment, and then the hardness can reach 63HRC.

Possess quality certification of ISO 9001:2000. Can pass CE test.

A wide range of specifications for you.

We can supply OEM service and can also produce according to your requirements./ OEM service available.

Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 3m

Thickness: 4.5mm

Material: ST52

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: What is the function of a concrete pump hopper grate pin?

- The function of a concrete pump hopper grate pin is to securely hold the grate in place, preventing it from shifting or becoming dislodged during the concrete pumping process.

- Q: Are there any specific cleaning and maintenance procedures for concrete pump spare parts?

- Yes, there are specific cleaning and maintenance procedures for concrete pump spare parts. For cleaning, it is important to remove any concrete buildup or residue from the spare parts regularly. This can be done by using a high-pressure water jet or by soaking the parts in a cleaning solution specifically designed for concrete. It is essential to follow the manufacturer's instructions when using cleaning agents to ensure the safety and effectiveness of the cleaning process. In addition to cleaning, regular maintenance is necessary to ensure the longevity and proper functioning of concrete pump spare parts. This includes inspecting the parts for any signs of wear, such as cracks or corrosion, and replacing them if necessary. Lubrication of moving parts, such as bearings or pistons, should also be done as per the manufacturer's recommendations. It is important to note that different concrete pump spare parts may require specific cleaning and maintenance procedures. Therefore, it is advisable to refer to the manufacturer's guidelines or consult with a qualified technician to determine the appropriate cleaning and maintenance procedures for each specific part.

- Q: What are the skills of concrete pump?

- ) need vertical piping, along with the increase of height is the potential increase of concrete circumfluence trend, therefore should be the level of pipeline laying length between the concrete pump and vertical pipe, to ensure that there is sufficient to prevent backflow resistance of concrete

- Q: What is the function of a concrete pump control lever?

- The function of a concrete pump control lever is to regulate the flow and direction of concrete being pumped, allowing the operator to precisely control the placement and distribution of concrete during construction projects.

- Q: Can I get spare parts for concrete pumps with different types of valve systems, such as S-valve or gate valve?

- Yes, it is possible to obtain spare parts for concrete pumps with different types of valve systems, including S-valve or gate valve. These spare parts are typically available through manufacturers, distributors, or specialized suppliers in the construction industry. It is important to identify the specific make and model of your concrete pump to ensure compatibility when purchasing spare parts.

- Q: How can a faulty battery affect the operation of the pump?

- A faulty battery can significantly affect the operation of a pump. Firstly, a faulty battery may not provide enough power to the pump, resulting in slow or weak pumping action. This can impact the pump's ability to generate the necessary pressure or flow rate, leading to inefficient or ineffective operation. Additionally, a faulty battery may cause intermittent power supply to the pump. This can result in inconsistent pumping action, with the pump starting and stopping sporadically. Such interruptions can create inefficiencies, reduce the pump's performance, and potentially cause damage to the equipment or system being operated. Furthermore, a faulty battery may not hold a charge for an extended period. This can limit the pump's runtime, requiring frequent recharging or replacement of the battery. In scenarios where a pump is needed for continuous or prolonged usage, a faulty battery can disrupt operations, leading to downtime and reduced productivity. Moreover, a faulty battery can also impact the overall lifespan of the pump. If the battery does not provide the necessary power consistently, the pump may experience strain or excessive wear, potentially shortening its operational life. Overall, a faulty battery can have various adverse effects on the operation of a pump, including reduced performance, inconsistent pumping action, limited runtime, potential damage, and decreased equipment lifespan. Regular maintenance and timely replacement of faulty batteries are crucial to ensure optimal pump performance and longevity.

- Q: Can concrete pump spare parts be inspected for dimensional accuracy before installation?

- Yes, concrete pump spare parts can be inspected for dimensional accuracy before installation. Before installing any spare parts, it is important to ensure that they meet the required specifications and dimensions to ensure proper functioning and compatibility with the concrete pump system. Inspection can be done using various methods such as visual inspection, measuring with precision instruments, and comparing the dimensions with the manufacturer's specifications. This process helps to identify any discrepancies or deviations in the dimensions of the spare parts, allowing for adjustments or replacement if necessary. Inspecting spare parts for dimensional accuracy before installation helps to ensure the smooth operation and longevity of the concrete pump system.

- Q: What is the purpose of a concrete pump hydraulic oil cooler?

- The primary function of a concrete pump hydraulic oil cooler is to keep the hydraulic oil in the system at the ideal temperature. The hydraulic oil powers the hydraulic system of the pump, which is responsible for operating different components like pistons, cylinders, and valves. While the pumping process is ongoing, the constant movement and pressure can cause the hydraulic oil to heat up. If the oil gets too hot, its viscosity decreases, which negatively impacts the overall efficiency and performance of the pump. Additionally, excessive heat can cause the hydraulic oil to deteriorate and break down, resulting in increased wear and tear on the pump's components. To prevent these problems, a concrete pump hydraulic oil cooler is utilized. It typically functions as a heat exchanger, transferring heat from the hydraulic oil to a cooling medium like air or water. This helps regulate the temperature of the hydraulic oil and keeps it within a safe operating range. By maintaining the optimal temperature, the hydraulic oil cooler guarantees that the hydraulic system functions efficiently and effectively. It also helps extend the pump's lifespan by reducing the risk of overheating and excessive component wear. Moreover, it preserves the quality of the hydraulic oil, allowing it to retain its lubricating properties and prevent any potential harm to the system. In conclusion, the goal of a concrete pump hydraulic oil cooler is to control the temperature of the hydraulic oil to optimize the performance, efficiency, and longevity of the pump's hydraulic system.

- Q: How often should concrete pump cylinders be inspected and replaced?

- Concrete pump cylinders should be inspected regularly, ideally on a daily basis, to ensure they are in proper working condition. The frequency of replacement depends on several factors including the intensity of usage, maintenance practices, and the quality of the concrete being pumped. Generally, concrete pump cylinders should be replaced when they show signs of significant wear and tear or when they no longer meet the required performance standards.

- Q: How can a faulty lubrication system affect the pump's performance?

- The pump's performance can be significantly affected in various ways by a lubrication system that is faulty. First and foremost, the responsibility of a lubrication system is to provide a thin layer of lubricant between the pump's moving parts. By doing so, it reduces friction and wear. However, if the lubrication system is faulty or inadequate, it can result in increased friction between the components. This, in turn, generates excessive heat and accelerates wear and tear. Ultimately, the efficiency and lifespan of the pump are reduced. Secondly, a faulty lubrication system can lead to inadequate lubrication for crucial components like bearings and seals. This inadequacy causes increased friction, heat, and ultimately, premature failure of these components. Consequently, there is increased downtime, costly repairs, and potential damage to other parts of the pump. Furthermore, a faulty lubrication system can also lead to the contamination of the lubricant. Leaks or improper maintenance can allow contaminants such as dirt, debris, or moisture to enter the system. These contaminants cause abrasive damage to the pump's internal components, resulting in reduced efficiency, increased wear, and potential failure. Lastly, the overall performance and energy consumption of the pump can be impacted by a faulty lubrication system. Insufficient lubrication increases the power requirements of the pump as it has to work harder to overcome friction and resistance. This, in turn, leads to higher energy consumption and increased operating costs. In conclusion, a faulty lubrication system severely impacts the pump's performance by causing increased friction, accelerated wear and tear, premature failure of critical components, contamination of the lubricant, and increased energy consumption. Regular maintenance and proper lubrication are crucial to ensure the pump operates optimally and has an extended lifespan.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 3MTR Thick 4.5MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords