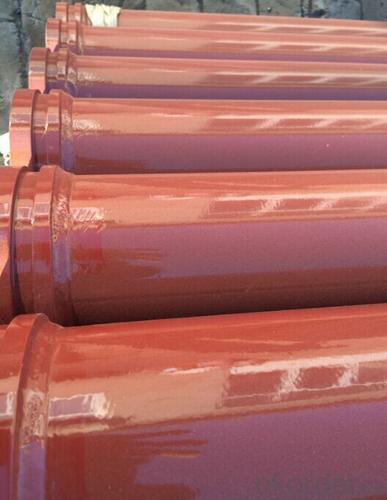

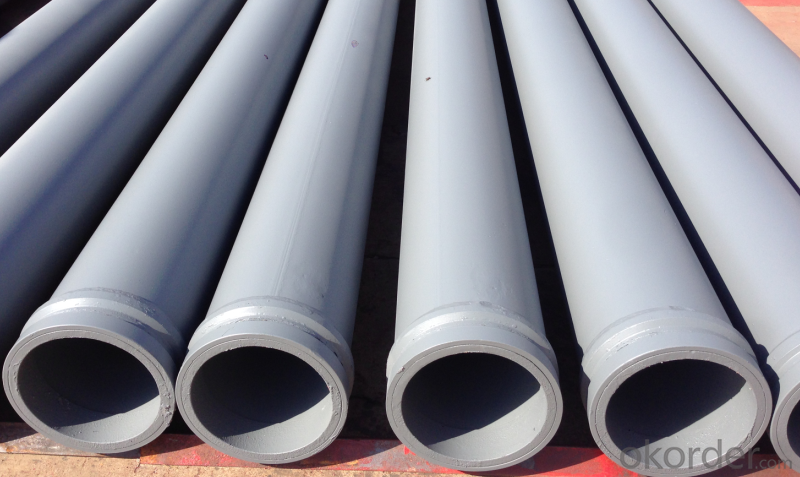

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 1MTR Thick 4.5MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.

2. Seaworthy packing or as customers’ request.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. A wide range of specifications for you.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 1m

Thickness: 4.5mm

Material: ST52

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: Can concrete pump spare parts be coated with UV-resistant coatings for outdoor applications?

- Concrete pump spare parts can benefit from the application of UV-resistant coatings to protect them from the damaging effects of UV radiation. These coatings are specially designed to prevent fading, cracking, and deterioration over time. By coating the spare parts, they are shielded from prolonged exposure to sunlight and other environmental factors, thus extending their lifespan and ensuring optimal performance outdoors. Furthermore, these coatings offer additional protection against weathering, including moisture, temperature fluctuations, and chemical exposure. As a result, it is highly recommended to coat concrete pump spare parts with UV-resistant coatings in order to enhance their durability and maintain their functionality when used outside.

- Q: What is the purpose of a concrete pump carbide wear plate?

- The purpose of a concrete pump carbide wear plate is to provide a durable and abrasion-resistant surface that allows for the smooth and efficient transfer of concrete from the pump to the desired location.

- Q: What are the types, classifications and specifications of concrete pump?

- In accordance with the export pressure rating label, divided into low pressure pump (5MPa), medium pressure and high pressure pump pump (6-10MPs) (>10MPa)

- Q: How often should concrete pump remote control antennas be inspected and replaced?

- To ensure optimal functionality, it is necessary to regularly inspect the antennas of the concrete pump remote control. The frequency of these inspections will vary depending on the usage and working conditions of the pump. In general, it is advisable to conduct inspections at least once a year or after every 500 hours of usage, whichever occurs first. However, if the pump is subjected to harsh environments or experiences frequent wear and tear, more frequent inspections may be required. It is crucial to carefully examine the antennas for any indications of damage, such as cracks, corrosion, or loose connections. If any damage is detected, immediate replacement of the antenna is essential to prevent disruptions in the remote control signal. By conducting regular inspections and promptly replacing antennas when necessary, the concrete pump can operate smoothly and efficiently.

- Q: What are the different types of concrete pump rubber hoses?

- There are several different types of concrete pump rubber hoses available in the market. 1. Steel Wire Reinforced Hose: This is the most common type of concrete pump rubber hose. It is reinforced with multiple layers of steel wire to provide maximum strength and durability. Steel wire reinforced hoses are suitable for high-pressure applications and can handle the heavy pumping of concrete with ease. 2. Textile Reinforced Hose: This type of hose is reinforced with multiple layers of textile fabric, such as nylon or polyester. Textile reinforced hoses are generally lighter in weight compared to steel wire reinforced hoses, making them easier to handle and maneuver. They are suitable for medium-pressure applications and are commonly used in smaller concrete pumps. 3. Fabric Hose: Fabric hoses are made from a single layer of fabric, such as nylon or polyester. They are lightweight and flexible, making them easy to handle and transport. Fabric hoses are suitable for low-pressure applications and are commonly used in small-scale construction projects. 4. Composite Hose: Composite hoses are made from a combination of different materials, such as rubber and plastic. These hoses are lightweight and highly flexible, making them suitable for applications where maneuverability is crucial. Composite hoses are commonly used in smaller concrete pumps and can handle both low and medium pressure. 5. Flanged Hose: Flanged hoses have flanges attached at both ends of the hose, which are used to connect the hose to the pump and the nozzle. Flanged hoses provide a secure connection and prevent any leaks or disconnections during the pumping process. They are commonly used in high-pressure applications and are suitable for large-scale construction projects. Overall, the choice of concrete pump rubber hose depends on the specific requirements of the project, including the pressure, size, and type of concrete being pumped. It is important to select the right type of hose to ensure efficient and safe concrete pumping operations.

- Q: Can concrete pump spare parts be customized according to specific requirements?

- Yes, concrete pump spare parts can be customized according to specific requirements. Many manufacturers offer customization options to meet the unique needs and preferences of their customers. This allows for the production of spare parts that are specifically designed to fit and function optimally with the particular concrete pump model or brand. Customization can include modifications in dimensions, materials, finishes, and other specifications to ensure compatibility and enhance performance. Furthermore, customization can also be done to meet specific environmental or project requirements, such as resistance to corrosion or extreme temperatures. Overall, the ability to customize concrete pump spare parts provides flexibility and ensures that the equipment operates efficiently and effectively in various construction projects.

- Q: How often should hydraulic oil filters be replaced in a concrete pump?

- The replacement frequency of hydraulic oil filters in a concrete pump is determined by several factors, such as operating conditions, oil type, and manufacturer recommendations. It is generally advised to replace these filters every 500 to 1000 operating hours or every 6 to 12 months, depending on which comes first. However, it is crucial to refer to the concrete pump's operation manual or the manufacturer's guidelines to determine the exact replacement interval for the hydraulic oil filters. Monitoring the filter's condition regularly and conducting routine maintenance checks can also aid in identifying the need for an earlier filter replacement than the recommended interval.

- Q: What is the function of a concrete pump hydraulic motor?

- The function of a concrete pump hydraulic motor is to provide the necessary power and force required to operate the concrete pump. The hydraulic motor is responsible for converting hydraulic energy into mechanical energy, which allows the pump to work efficiently and effectively. It drives the pumping mechanism, allowing the concrete to be pumped through the pipeline and delivered to the desired location. The hydraulic motor also controls the speed and direction of the pump, enabling precise placement of the concrete. Overall, the concrete pump hydraulic motor plays a crucial role in ensuring the smooth operation and successful delivery of concrete in construction projects.

- Q: How to choose concrete pump?

- A concrete pump motor power is a prerequisite for determining the export pressure and transport volume, the motor power is certain, will increase pressure to reduce the amount of transportation; on the contrary, reduce export pressure, will make the delivery volume increase

- Q: How can a faulty outrigger affect the stability of the pump?

- A faulty outrigger can significantly affect the stability of a pump. The outrigger is an essential component that helps to support and balance the pump during operation. It acts as a stabilizer and prevents the pump from tipping over or vibrating excessively. If the outrigger is faulty, it may not provide the necessary support and stability required for the pump to function properly. This can lead to various stability issues. For example, the pump may become more prone to tipping over, especially if it is subjected to uneven surfaces or strong vibrations. This can be extremely dangerous, especially if the pump is dealing with hazardous or flammable materials. Additionally, a faulty outrigger can cause the pump to vibrate excessively. Vibrations can lead to increased wear and tear on the pump, resulting in premature failure of critical components. Excessive vibrations can also cause damage to the surrounding infrastructure or equipment, leading to costly repairs or even accidents. Furthermore, a faulty outrigger can affect the accuracy and efficiency of the pump's operation. If the pump is not properly stabilized, it may not be able to maintain a consistent flow rate or pressure, affecting its performance. This can result in inefficiencies, increased energy consumption, and even reduced productivity. In conclusion, a faulty outrigger can have a detrimental impact on the stability of a pump. It can increase the risk of accidents, cause excessive vibrations, and affect the pump's performance and efficiency. Regular maintenance and inspections are crucial to ensure that the outrigger and other support systems are functioning correctly to maintain the stability and reliability of the pump.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 1MTR Thick 4.5MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords