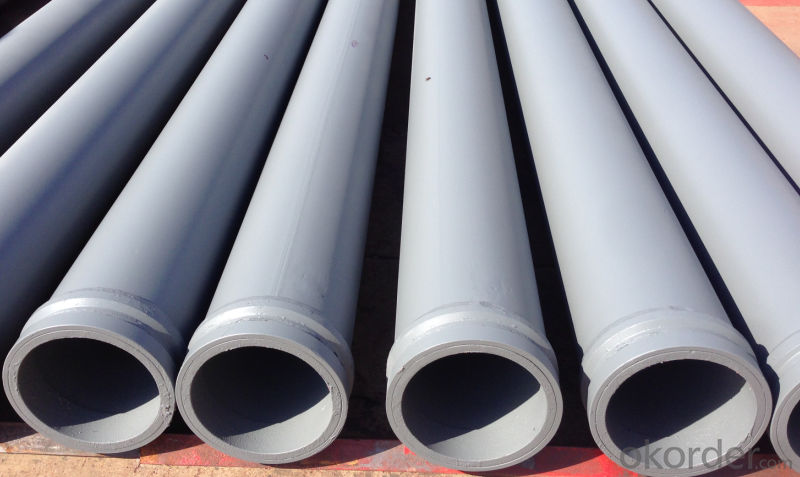

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 1MTR Thick 3.2MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.

2. Service life:7000-80000 CBM Concrete.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. Normal and female/male flanges are both available to suit for normal or high pressure concrete pumping

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 1m

Thickness: 3.2mm

Material: ST52

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: Are there any specific training or certifications required for handling and installing concrete pump spare parts?

- Yes, there are specific training and certifications required for handling and installing concrete pump spare parts. Due to the specialized nature of the equipment and the potential risks involved, individuals who handle and install concrete pump spare parts should undergo proper training and obtain relevant certifications. Firstly, it is essential to have a thorough understanding of the functioning and components of concrete pumps. This knowledge can be acquired through comprehensive training programs offered by equipment manufacturers, industry associations, and vocational schools. These training programs cover topics such as pump operation, maintenance, troubleshooting, and safety protocols. Additionally, specific certifications may be required depending on the jurisdiction or industry standards. For example, the American Concrete Pumping Association (ACPA) offers a certification program known as the ACPA Operator Certification. This certification requires individuals to demonstrate their knowledge and skills related to concrete pumping equipment, including the handling and installation of spare parts. Obtaining these certifications ensures that individuals are equipped with the necessary knowledge and skills to handle and install concrete pump spare parts safely and efficiently. It also helps in maintaining compliance with industry regulations and standards. It is important to note that the specific training and certification requirements may vary depending on the region, industry, and the type of concrete pump being used. Therefore, it is recommended to consult local regulations and industry guidelines to ensure compliance with the necessary training and certification requirements for handling and installing concrete pump spare parts.

- Q: What is the function of a concrete pump outrigger?

- The function of a concrete pump outrigger is to provide stability and support to the concrete pump while it is in operation. The outrigger extends from the sides of the pump and is used to distribute the weight of the pump and concrete being pumped, preventing it from tipping over or causing any instability.

- Q: What are the different types of concrete pump hopper vibrators?

- On the market, one can find various concrete pump hopper vibrators. Their purpose is to ensure a smooth flow of concrete through the hopper and into the pumping system. 1. Electric Vibrators: The most commonly used hopper vibrators are powered by electricity. They are typically attached to the hopper's side and employ an electric motor to generate vibrations that facilitate the movement of concrete. 2. Pneumatic Vibrators: These vibrators rely on compressed air as their power source and are commonly employed in situations where electricity is not readily accessible. By utilizing air pressure, they create vibrations that aid in the continuous flow of concrete. 3. Hydraulic Vibrators: Larger concrete pumping systems often utilize hydraulic vibrators, which derive their power from hydraulic fluid. These vibrators can be more robust than their electric or pneumatic counterparts, making them suitable for heavy-duty applications. 4. Rotary Vibrators: To move the concrete, these vibrators employ an eccentric weight that spins, resulting in vibrations. They are frequently used when a high frequency of vibration is necessary. 5. Turbine Vibrators: These vibrators employ a turbine mechanism to generate vibrations. They are commonly employed when a low frequency of vibration is desired. 6. Ball Vibrators: These vibrators use a ball housed within a casing to generate vibrations. They are frequently utilized in smaller concrete pumping systems and can be easily mounted onto the hopper. In conclusion, the choice of the most suitable concrete pump hopper vibrator for a specific application depends on various factors, including the size and type of the concrete pumping system, the desired frequency and intensity of vibration, and the availability of power sources.

- Q: How often should I replace concrete pump spare parts?

- The frequency of replacing concrete pump spare parts depends on several factors such as the quality of the parts, the intensity of usage, and the maintenance practices. However, as a general guideline, it is recommended to inspect and replace worn or damaged concrete pump spare parts on a regular basis, typically every 6 to 12 months, to ensure optimal performance and avoid potential breakdowns or safety hazards.

- Q: Are there any specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts. It is important to follow the manufacturer's instructions and recommendations provided with the seal kits or O-rings. The guidelines typically include steps such as cleaning and preparing the installation area, ensuring proper alignment and fit, utilizing appropriate lubrication, and applying the correct amount of torque during installation. Adhering to these guidelines helps ensure proper functioning and longevity of the concrete pump spare parts.

- Q: What is the role of a concrete pump spectacle plate?

- The role of a concrete pump spectacle plate is to provide a stable and secure platform for the concrete pump to rest on during operation. It acts as a support base for the pump, ensuring that it remains steady and balanced while pumping concrete. The spectacle plate is typically made of durable materials such as steel or alloy, capable of withstanding the weight and pressure exerted by the pump. Its design includes various features such as slots or holes to allow for the attachment of accessories like clamps or pipes, enabling the smooth and efficient transfer of concrete from the pump to the desired location. Additionally, the spectacle plate may also have adjustable elements to allow for positioning and alignment adjustments, ensuring accurate placement of the concrete. Overall, the spectacle plate plays a vital role in maintaining the stability and functionality of the concrete pump, contributing to the successful completion of construction projects.

- Q: What is the washing process of the concrete pump pipe?

- Connect the reducing pipe and close the discharge door. Pour water directly into the hopper.

- Q: How often should hydraulic oil filters be replaced in a concrete pump?

- The frequency of replacing hydraulic oil filters in a concrete pump depends on various factors including the operating conditions, the type of oil used, and the manufacturer's recommendations. Generally, it is recommended to replace hydraulic oil filters in a concrete pump every 500 to 1000 operating hours or every 6 to 12 months, whichever comes first. However, it is essential to consult the concrete pump's operation manual or the manufacturer's guidelines to determine the specific replacement interval for the hydraulic oil filters. Regularly monitoring the filter's condition and conducting routine maintenance checks can also help in determining if a filter replacement is needed sooner than the recommended interval.

- Q: Are there any regulatory requirements for the quality and standards of concrete pump spare parts?

- Yes, there are regulatory requirements for the quality and standards of concrete pump spare parts. These requirements ensure that the spare parts meet certain standards of safety, performance, and durability. Regulatory bodies, such as governmental agencies or industry associations, often establish these requirements to protect consumers and ensure the proper functioning of concrete pumps. Some of the common regulatory requirements for concrete pump spare parts include: 1. Certification: Spare parts may need to be certified by an authorized organization or undergo a specific testing process to demonstrate that they meet the required quality and performance standards. This certification helps ensure that the spare parts are safe and reliable. 2. Material Standards: There may be specific material standards that the spare parts must comply with. For example, the materials used in the construction of the spare parts may need to meet certain strength, corrosion resistance, or temperature resistance requirements. 3. Design and Manufacturing Standards: The design and manufacturing processes of the spare parts may need to adhere to certain standards. This includes guidelines on dimensions, tolerances, manufacturing techniques, and quality control procedures to ensure consistent and reliable performance. 4. Performance and Compatibility Standards: Spare parts should be designed and manufactured to perform within specific parameters and be compatible with the concrete pump system they are intended for. This ensures that the spare parts will function properly and safely when installed in the pump. 5. Documentation and Labeling: Regulatory requirements often mandate that spare parts come with proper documentation, including user manuals, installation instructions, and maintenance guidelines. Additionally, labeling requirements may be in place to clearly identify the spare parts and their specifications. It is important for manufacturers, suppliers, and users of concrete pump spare parts to be aware of and comply with these regulatory requirements to ensure the safety and effectiveness of the concrete pump system.

- Q: How can one identify the need for replacement of concrete pump spare parts?

- One can identify the need for replacement of concrete pump spare parts by observing any signs of wear and tear, such as cracks, leaks, or damage to the components. Additionally, a decrease in pump performance, unusual noises, or difficulty in operation can indicate the need for replacement. Regular maintenance and inspection can also help in identifying any potential issues with the spare parts that may require replacement.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 1MTR Thick 3.2MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords