Concrete Formwork Scaffolding System|As1576 Steel Construction Kwikstage CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Concrete Formwork Scaffolding System|As1576 Steel Construction Kwikstage

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Brand Name:

Surface:

Material.:

Thickness:

Descriptions of Concrete Formwork Scaffolding System|As1576 Steel Construction Kwikstage

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

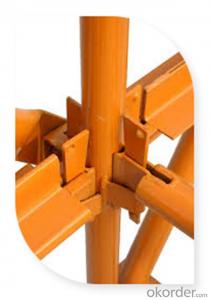

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

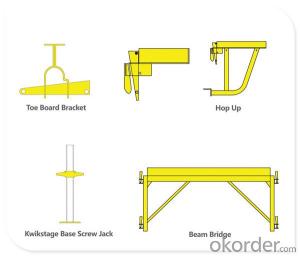

The Accessories of Concrete Formwork Scaffolding System|As1576 Steel Construction Kwikstage

Kwikstage Products: Standard; Ledgers; Transom; Steel Plank; Hop Ups; Diagonal Braces; Tie Bars; Toe board Brackets; End Toe Board Brackets; Double C Clip; External Cup Standard

Props and Formwork: Formwork Prop; Formwork Jacks ; Shoring Jacks

Other Accessories: Ladder Beams; Aluminium Stair ; Base Jack; Swivel Jack ; Steel Pallet; Steel Mesh Pallet.A)Kwikstage Standard

Length: 3.0m;2.5m;2.0m;1.5m;1.0m;0.5m Thickness: 4mm Surface: Painted or Hot Dipped Galvanized Certificate: AS / NZS 1576.3-1995 B) Kwikstage Ledgers

Surface painted or hot dipped galvanized Thickness 3.2mm; 3mm Length 2.4m; 1.8m; 1.2m; 0.7m Certificate AS / NZS 1576.3-1995 C) Kwikstage Transom

Surface painted or hot dipped galvanized Thickness 5mm Length 2.4m;1.8m;1.2m;1.0m;0.7m D)Kwikstage Scaffolding Steel Board / Steel Plank

Length 2.4m ; 1.8m; 1.2m; 0.7m Thickness 1.8mm galv.iron sheet Certificate AS 1577-1993 FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Cantilever scaffold technical disclosure

- Vertical bar, vertical horizontal bar (large cross bar) of steel pipe length of 3-6 meters, horizontal horizontal bar (small cross bar) steel pipe length of 1.1~1.3 meters, the lateral bracing steel pipe length of 3-4 meters.

- Q: What are the components of a mobile scaffolding

- The utility model relates to a standard steel pipe scaffold which is connected with the main structure of the wall and is connected with the main structure of the building.

- Q: Im in college football, I would be puting on and taking off my helmet, I usually keep it on though during practice...but would it be wise for me to get an industrial piercing a couple months before 2 a days and the football season...would the sweat maybe infect my ear, but I am a very clean guy? thanks, if you have an answer it will help my decision.....

- trust me, bro. bad idea. industrials are very tempermental at best. your helmet will cause every problem possible. any descent piercer would tell you the same. don't do it. they take up to a year to heal soif you really want one, quit football or wait til you're out of school.

- Q: What's the film where gene Kelly dances on scaffolding? And at a gym?

- I think it's Living in a Big Way.... I could be wrong...

- Q: Can anyone give a very brief description on all three scaffold scenes in The Scarlet Letter?

- oh dang u have to read that story too ! man i had to read it and watch the movie ! so boring. What grade are u in ?

- Q: Right! I've heard from so many different people about this. Some say that you should never twist an industrial because it can damage the delicate newly healing skin cells. Others say that you must twist it to prevent the jewelry from healing attached to the skin and to be able to clean it properly.There really doesn't seem to be a definitive answer!My piercer has said not to twist it, so I haven't been, and I'm happy that the piercing is clean enough, etc. However I'm interested in whether any of you out there have found that not twisting it can damage it more than doing so.Thanks

- My piercer told me to move the bar up and down, not to twist it around. And now, it's a year and a few months later and I've never had any problems with mine. It healed perfectly.

- Q: Standard Specification for bowl buckle scaffold

- A new type of scaffold developed in China

- Q: Which hurts less, the piercing at the top of the ear, or the piercing from one side of the upper ear to the other?Thanks. =)

- The first piercing of the scaffold will feel the same as getting your helix done. The second will hurt a bit more. The healing of a scaffold, however, will probably be more painful than just one helix piercing and will take a bit longer.

- Q: Specification and type of scaffold erection

- 2 fasteners should be qualified factory, where brittle crack, deformation, sliding wire shall not be used. 3 steel scaffolding should be 2 ~ 3mm thick No. 3 steel plate, with the length of 1.4 ~ 3.6m, 23 ~ 25cm, width of rib height should be 5cm, available on both ends of connecting device, surface with anti slip hole, where the crack distortion may not be used.

- Q: Compared to Pankou scaffolding and scaffolding have what distinction, what are the advantages

- 5, Pankou scaffold disassembly do very simple, a person needs only a hammer can do the installation and removal of the entire process. Construction efficiency greatly improved, two construction workers only 1 days to complete the construction site 350m3.

Send your message to us

Concrete Formwork Scaffolding System|As1576 Steel Construction Kwikstage CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords