Complete Set of Quenching Equipment (Good Quality)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 6 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application Scope

Quenching heat treatment of metal workpiece.

Function Structure

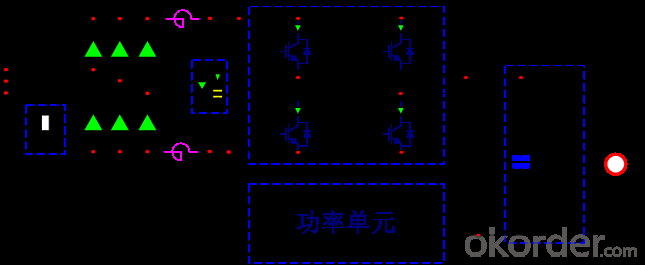

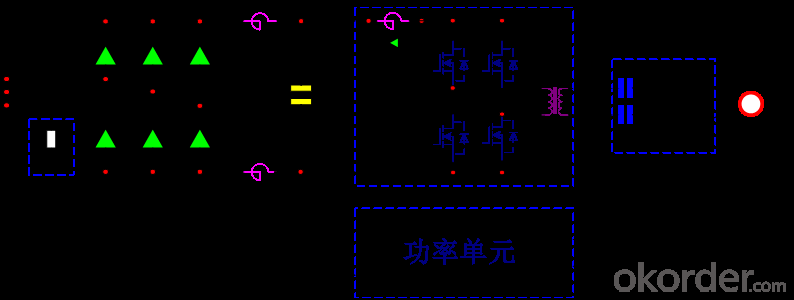

Complete set of quenching equipment is mainly composed of quenching machine tool, quenching power supply (medium frequency power supply, high frequency power supply, super-audio frequency power supply) and cooling equipment. The quenching machine tool is composed of machine tool bed, upper and lower clamping mechanism, clamping and rotating mechanism, cooling system, quenching liquid circulation system and electric control system. Customer can select quenching machine tool as per quenching technics. For special workpiece or technics, the quenching machine tool can be designed and manufactured according to heating technics requirement.

Quenching power supply generally selects parallel induction heating power supply. In order to stabilize quenching frequency to adapt multiple workpiece specifications, tank circuit of quenching power supply need to select quenching transformer.

Technical Features

Ø Perfect structure design

1.Integration design of switchgear rectifying cabinet and inverter output cabinet, with compact structure and small size.

2.The power supply selects DC chopper mode to ensure the grid side power coefficient≥0.92 and a relative lower harmonic content.

3.High standard electromagnetism compatibility design, electromagnetism radiation meets national standard. Closed cabinet design, meeting rigor environmental requirements on site.

4.The shape of quenching inductor is decided by workpiece and quenching technics, and the inductor is well-made.

Ø control system

1. PLC program control or CNC numerical control is optional.

2. AC full digital servo control, numerical control system adopts every advanced control circuits to reduce position tracking error to minimum, and compensate nonlinear error of static/kinetic friction of mechanism system automatically.

3. Quenching machine tool and power supply has perfect protection function with reliable working and low failure rate.

* Can be customized according to user’s requirement.

* equipment selection

Ø penetration heating:A kind of heating method that heat treatment layer is less than current thermal penetration depth, and with suitable specific power density.

Workpiece surface superheat is small, with thin thermal transition layer and high heating efficiency (quenching efficiency is 30~40%)

Ø power:

power density (specific power):The ratio of the power acquired by the workpiece to the heating surface.

| kW/cm2 | simultaneity heating quenching | continuous heating quenching | ||

| Quenching method | specific power scope | commonly used specific power | specific power scope | commonly used specific power |

| M.F. quenching | 0.5~2.0 | 0.8~1.5 | 1.0~4.0 | 2~3.5 |

| H.F. quenching | 0.5~3.5 | 0.8~2.0 | 1.0~4.0 | 2~3.5 |

For workpiece with complicated shape (gear, keyway, eyelet), select lower limit.

For inner hole, flat surface, simple shape compact structure shaft and big workpiece, select upper limit.

Ø power:

For workpiece with complicated shape (gear, keyway, eyelet), the frequency should be lower.

Ø power distribution:

:(simultaneity factor)0.8~0.9

- Q: Selection of heat preservation material for industrial furnace

- In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade. Excellent chemical stability; excellent thermal stability; excellent tensile strength; low thermal conductivity; low thermal capacity; excellent sound absorption and noise reduction performance.

- Q: What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q: Should the industrial furnace shell cool down?

- The function of furnace shell is beautiful, protective lining, fixed function accessories and so on.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- Heat treatment furnace is mainly for the mechanical processing and casting industry workpiece annealing, quenching, carburizing, quenching and tempering, heat treatment equipment.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Basically, no industrial furnace manufacturer can do all types of stoves.Often associated with the industry is very large,so your ranking is basically meaningless.

- Q: What are the combustion equipments used in industrial boilers?

- Main auxiliary equipment for general boilers:1. domestic appliances 2. civilian gas boiler 3. industrial gas furnace.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: How many kinds of industrial electric furnaces are there?

- Electric furnace is divided into four categories: resistance furnace, induction furnace, arc furnace and special electric furnace according to the different ways of electric heating.

- Q: How to use industrial furnace equipment?

- If it is water cooling furnace door, but also to ensure the smooth flow of pipes, winter pipes are not frozen. When the boiler is in a limited position, the interlocking device for cutting off the power supply shall be provided when the furnace is in and out, and the number of broken wires in the pitch of the steel wire shall not exceed 10%, and the counterweight of the furnace door shall be reliably hung.

- Q: What is the difference in structure between industrial furnace and boiler?

- At the same time, the working environment is relatively poor, the structure should be sturdy and durable, the transfer mechanism (generally) to stable and durable low failure rate, the insulation layer must be thick enough and the economy, the steel structure housing materials used to be enough.

Send your message to us

Complete Set of Quenching Equipment (Good Quality)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 6 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords