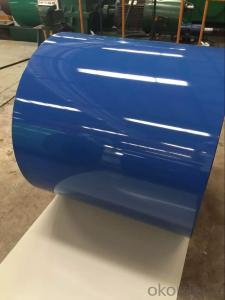

color steel coil/prepainted galvanized steel coil/PPGI for roofing and construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | waterproof paper+steel sheet+outer/inner protective circles+side protective guard+wood pallet |

| Delivery Detail: | within 30 days after received deposit or L/C at sight |

Specifications

1.color steel coil

2.thickness:0.12-2.0mm

3.width:900-1250mm

4.certificate:ISO 9001:2008

5.manufacturer

Company introduction of color steel coil :

Shandong Luli Steel Co. Ltd, founded in 1993, is a holding company of Luli Group, located in Weifang city, Shandong

province,China. It is a joint steel manufacturer with 2 PPGI production line,1 GI and Aluzinc production line,

15 different kinds of corrugated steel roofing sheet machines and 5 different kinds of load bearing plate

machines.Products have passed ISO9001 international quality system authentication.Leading products include:

(1)0.12mm-2.0mm*900mm-1250mm*C prepainted galvanized steel coil

(2)0.15mm-2.0mm*900mm-1250mm*C hot dipped galvanized steel coil and aluzinc steel coil

(3)0.30mm-1.0mm*750mm-1075mm*C corrugated steel roofing sheets

(4)0.80mm-1.2mm*600mm-720mm*C load-bearing plates

Products have exported to Korea, Japan and Southeast Asia with good reputation.Luli Steel Co., Ltd warmly welcomes

all the customers to come to visit factory.If you are interested in our products,pls feel free to contact me.You could

also add me on SKYPE or WHATSAPP to contact in time.Detail contact information as follow:

Contact person | |

SKYPE | |

Trademanager | |

Moble | |

Tel. | |

Fax. | |

Website |

Production introduction of color steel coil :

Commodity | PPGI/PPGL |

Standard | JIS G3302, JIS G3313, ASTM A653, GB/T2518-88, GB11253-89,, BS, ect. |

Grade | SGCC,CGCC,SGCD,SPCC,DX51D,DX52D,DX53D |

Thickness | 0.12mm-2mm |

Width | 900-1250mm |

Coil ID | 508mm/610mm |

Coil Weight | 3-6tons |

Zinc Coating | Z20-Z270g/m² |

Color | sea blue,white grey , bright red or according to RAL color system |

Thickness of coating | Top coating:12-25 microns,back coating:5-8microns |

Technique | Cold rolled galvanized steel coil,galvalume steel coil |

Surface Production | PE,PVDF,SMP,HDP,ect. |

Application | Roofing, Corrugated Roofing Making,Outside of the buildings,Structure,Wall, Deep Drawn |

Delivery time | About 30 working days after received client deposit or irrevocable L/C at sight |

Shipment | Container or bulk |

Payment Term | L/C,T/T |

Production line instruction of color steel coil :

loading coil-uncoil-stitching machine-entry looper-first time alkali cleaning-second time alkali

cleaning-first time hot water washing-second time hot water washing-epoxy primary coating-primary coating drying-first time water quenching-polyester top coating-high tempreture top coating dry-second time water quenching-outlet looper-cut down-unloading coil-weighing-packing and warehousing

- Q: What is the maximum thickness of steel coils?

- The specific application and manufacturing process play a significant role in the potential range of maximum thickness for steel coils. Typically, steel coils may vary from a few millimeters to several centimeters in their maximum thickness. Determining factors include the intended use of the coils, the type of steel employed, and the capabilities of the manufacturing equipment.

- Q: What metals contain steel? It can be anything except soft iron or steel.

- Metals do not contain steel. Steel is an alloy of purified iron and carbon, and sometimes with other metals, such as nickel, chromium, or molybdenum to make it stainless or to change its hardness or other properties. It's like asking what cereals contain Cheerios. It doesn't really make sense. Other metal alloys contain iron, which is an element and the main ingredient of steel. Maybe you should be asking which metal alloys contain iron? That's more like asking which cereals contain whole grain oats. Now that's a question that can be answered by reading the ingredients labels on your standard boxes of metal alloys :-)

- Q: which metals have a higher density than steel? and how does the density compare to steel( example: tungsten carbide is 2x [i think] more dense than steel.)

- Stainless steel 7480 -8000 kg/m^3 Brass 8100 -8250 Cobalt - 8746 Copper 8930 Gold 19320 Lead 11340 Mercury 13593 Molybdenum 10188 Nickel 8800 Platinum 21400 Plutonium 19800 Silver 10490 Tungsten 19600 Uranium 18900

- Q: does anyone out there know where to get a good deal on a pedal steel guitar? i am from northern indiana and i'm willing to travel some if i have to.i am just getting into pedal steel guitar and i really don't have any idea what i need. i don't know how to play a guitar (i do know how to play the piano and the drums) at all but i want to learn to play the pedal stell guitar and i can't do that without getting one first so, if anyone can help me out i would greatly appreciate it! :o)

- Pedal steel guitars are a challenge to learn but they're a great instrument. More, even a starter pedal steel is going to run you $800 or so. Elderly Instruments in Lansing, Michigan sells a Carter brand starter pedal steel for $795 which is about as low as I've seen new ones. It has 3 foot pedals and 4 knee levers so it's nicely equipped. From northern Indiana it's not that far I would think. Good luck.

- Q: What is the maximum stacking height for steel coils?

- The maximum stacking height for steel coils depends on various factors such as the size and weight of the coils, as well as the strength and stability of the storage facility. Generally, it is recommended to stack steel coils up to a height of 3 to 5 coils, ensuring proper weight distribution and stability to prevent damage or accidents.

- Q: Are steel coils affected by temperature changes?

- Yes, steel coils are indeed affected by temperature changes. Steel is known to expand and contract with temperature fluctuations. When exposed to high temperatures, steel coils expand, and when subjected to low temperatures, they contract. These thermal expansions and contractions can cause changes in the dimensions and shape of the steel coils, which can potentially affect their performance and functionality.

- Q: How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials by being unwound and flattened to create the wire used for fencing. The steel wire is then further processed and shaped into different forms, such as chain link or barbed wire, to meet specific fencing needs.

- Q: Can steel coils be stretched?

- No, steel coils cannot be stretched as steel is a rigid material and does not have the ability to be stretched like other elastic materials.

- Q: I'm trying to make a corset but I can't find any steel boning in my area. Any clue as to what materials I could buy to to make my own bones, or anything that would work similarly?I know there are places to buy it online, but the cost of shipping makes it barely seem worth it.

- Hi, buy the original bones. They are designed to corset's load. If you use any substitute material it could break and it could be cause of injuries. Use google for link to corset's bones suppliers. Look on:

- Q: What are the different types of steel coil packaging methods?

- There are several types of steel coil packaging methods, including shrink wrapping, strapping, wooden crates, and steel or plastic bands.

Send your message to us

color steel coil/prepainted galvanized steel coil/PPGI for roofing and construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords