Color Coated Aluminum Coil AA1100 Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

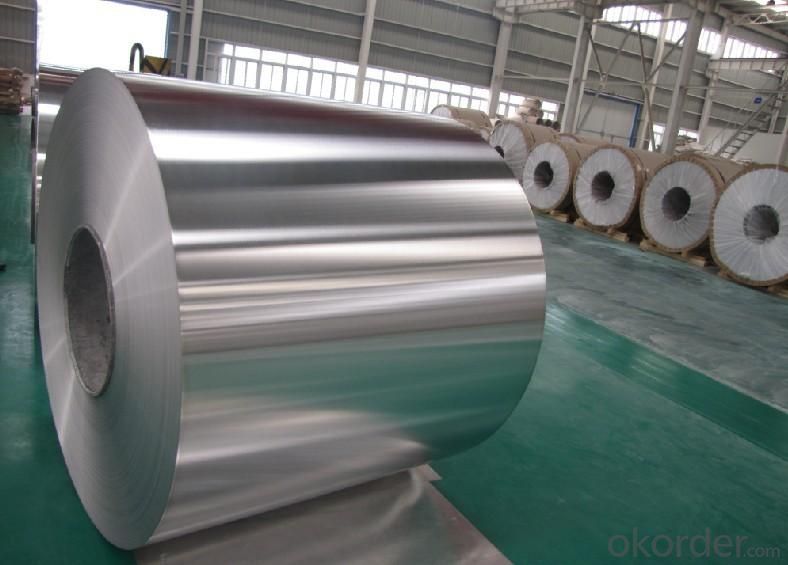

Color Coated Aluminum Coil AA1100 Aluminum Alloy

1. Grade

| Series: | 1100 etc. |

| Series: | 3003 3004 3005 etc. |

| Series: | 5006, 5052 |

| Series: | 8011 etc. |

2. Thickness

| Plate Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

| Coil Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

3. Description

Alloy | AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc , etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.1mm to 1.2mm |

Width | Standard width:1240mm, 1270MM |

Special width:1000mm, 1200mm, 1240mm, 1270mm, 1520mm, 1620mm | |

Diameter | Standard dia:1200mm |

Interior dia: 150mm,405mm, 500mm, 505mm, 510mm | |

outer diameter: 1200mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating thickness | PE:>=16 micron , PVDF:>=25 micron |

Protective film | As per customer’s request |

Coating paint | PVDF, PE(Polyester), epoxy, polyamide, polyurethane |

Color | Soid, metallic, high gloss,stone,timber,brush,mirror,sparkling, RAL or by customer requirements. |

Weight | As per customer’s request |

| Surface | Embossed, mill finish, coated |

| Gloss | 10-100% |

| Coating Hardness (pencil resistance) | More than 2h |

| Coating adhesion | 1J |

| Impact Resistance | No peeling or cracking(50 kg/cm) |

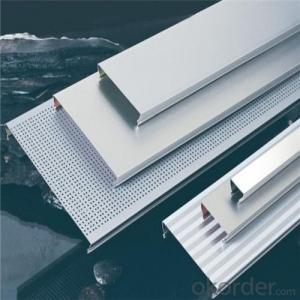

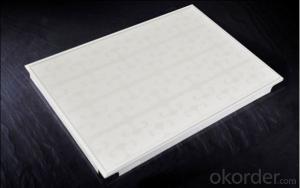

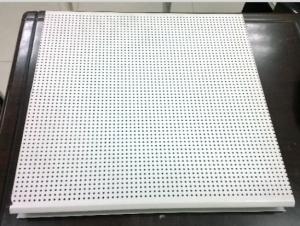

| Application | ACP,wall cladding,facades,roofs and canopies,ceilings,signboards,blind window,display platforms,electrical panels,etc |

| Coating Thickness | PE coating:more than 16 micron |

| PVDF coating:more than 25micron |

4. FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: Aluminum slab plate 300 × 300 panel lights up to the number of watts

- 300300's routine is 24W The largest words can also reach 30W drive current can be transferred Details can be asked on the 1688 platform, China Green Fu photoelectric

- Q: What is the brushed aluminum plate

- The following is a detailed description of the surface treatment of the plate: 1, coating process: directly on the aluminum substrate on a high temperature die-casting thickness of 18-25C PVC film, the disadvantage is the surface easy to change color. 2, roller coating process: the surface is coated with a layer of polymer coatings, the advantage is durable and difficult to change color. 3, roller screen printing: roller on the basis of the plate and a screen printing, the effect is to make a single roller has become rich color. (Also known as hot infiltration printing): and silk screen is the same as in the roller coating on the basis of printing, but the thermal penetration of the ink through the high temperature method of sublimation to penetrate into the roller coating inside , The face is touched is not feel rugged, and thus feel that this is the difference between the screen printing, thermal penetration printing is a digital way, the color can be composed of N kinds. But silk screen can only be composed of one by one color. 4, matte process: in the aluminum plate on the top of the drawing, and then after the process of manufacturing varnish. Currently on the market the most common of a plate.

- Q: Aluminum veneer, aluminum ceiling installation to pay attention to what the problem

- The aluminum board is connected to the keel by the surrounding aluminum horn and fixed to the keel with screws. In the installation is strictly prohibited distortion, deformation, bruises, from top to bottom layer of aluminum veneer surface of the protective adhesive tape to tear off, while layer by layer synchronization split, dismantling should pay attention to protect the aluminum veneer, Scratches; pay attention to the installation of precision control, vertical vertical plane 2mm; surface flatness 3mm; corners Founder 3mm; seam straight 0.5mm. The project in the installation process in strict accordance with the requirements of construction, and adhere to the process can not be carried out on the next process of construction quality control principles. In addition to taking into account the facade of the decorative effect, but also to consider the thermal expansion of the thermal expansion after the amount of seams must be sealed with a weathering rubber to prevent gas infiltration and rain leakage ① fully clean the board The gap to ensure that the adhesive surface clean, and to dry; ② to adjust the depth of the seam, to avoid the three sides of the glue, the seam filled with PVC foam material (small round bar); ③ glue should be applied Flat, remove the excess glue; ④ pay attention to post-mortar care, glue in the incomplete hardening before, do not contaminated with dust and scratches

- Q: How to dismantle the aluminum plate

- The intensity can be pulled out slightly, if it is a strip of the ceiling that pushed from the wall on the edge of a piece of the inside can be taken down, and then followed down, but after all strenuous.

- Q: Who has CAD - 600 * 600 mineral wool board ceiling 300 * 300 aluminum slab plate ceiling node map urgent use

- Aluminum slabs are usually used in home improvement market.

- Q: Recently home house in the decoration, to see a lot of integrated ceiling model. Now very depressed is the integrated ceiling and aluminum buckle plate integrated ceiling in the end what is the difference? Is it the same thing? Very depressed ~

- The difference is that the integrated ceiling is connected with electrical appliances, aluminum plate is a board

- Q: Kitchen aluminum plate inlaid with lights, lights do not change how to install how the equipment installed

- Aluminum slabs are the easiest to install in all lights! The aluminum gusset plate is stuck on the keel, with a small screwdriver (or small blade) from the aluminum buckle seam edge tilt a corner! Slowly pull down the lampshade by hand, with the same method in the next pull down a piece of buckle, see the lamp body is stuck in the keel above, a hand to pull the keel outward, the other hand to the top of the lamp , Light on the Kai down, and know how to unload the unloading to understand how installed, and installed this kind of lamp a pliers a small screwdriver to get!

- Q: Integral aluminum slabs hanging ceiling corners can be used to glue it

- If it is a tile wall can be used to glue, if it is other walls have to use a nail

- Q: Aluminum buckle board edge of this used to do

- Is used to fix the need to cut off the buckle to make the gap between the pinch and the edge of the minimum in the fight when the glass glue more beautiful look good, no cut on the need not directly on the line

- Q: And aluminum buckle board compared to which inexpensive? If the decoration of the house should be how to choose? Such as what is the bathroom / kitchen what / aisle what balcony with what

- Of course, aluminum plate well, but the ordinary family or choose steel plate ceiling is better, should pay attention to the purchase of plastic wall thickness. Decoration boss recommend you use steel plate I think we can adopt the following look at these two materials comparison: Plastic plate is improved by the second generation of ceiling material PVC, also known as UPVC, steel plate is the advantage of lower prices, thermal insulation performance, rich colors, production and installation is simple.

Send your message to us

Color Coated Aluminum Coil AA1100 Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords