Cold rolled steel coils jsc270c from china supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 62450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold rolled sheet steel products are used in a wide variety of end applications such as appliances, automobiles - exposed as well as unexposed parts, electric motors, plumbing fixtures, drum manufacturing, shelving, furniture, doors, toolboxes, tubing products, unexposed construction products, as well as many other areas of manufacturing.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

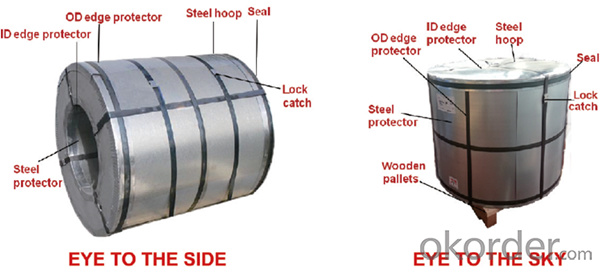

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: How are steel coils used in the manufacturing of industrial compressors?

- Steel coils are used in the manufacturing of industrial compressors as they are shaped and formed into various components of the compressor, such as the casing, cylinder, and piston. The steel coils provide strength, durability, and stability to these components, allowing the compressor to withstand high pressure and perform efficiently in industrial applications.

- Q: How are steel coils used in the manufacturing of mining equipment?

- Steel coils are used in the manufacturing of mining equipment for various purposes, such as forming the structural components, building frames, and creating durable and robust machinery. These coils are often shaped, cut, and welded to construct mining machinery that can withstand the harsh conditions and heavy-duty operations in the mining industry.

- Q: who are the 7 best steel guitar players ever?

- 1.Jerry Byrd 2. Buddy Emmons 3. Jimmy Day 4. LLoyd Green 5. Pete Drake 6. Hal Ruggs 7. Welbon Myrik

- Q: How are steel coils classified based on their thickness?

- Steel coils are classified based on their thickness into different categories such as light gauge, medium gauge, and heavy gauge.

- Q: How are steel coils processed and treated?

- Steel coils are processed and treated through a series of steps to ensure their quality and suitability for various applications. The process begins with uncoiling the steel coil, which involves removing the outer layers of protective wrapping and unwinding the coil. Once uncoiled, the steel is inspected for any defects, such as cracks or uneven surfaces. Next, the steel coil goes through a cleaning process to remove any dirt, oil, or rust present on its surface. This is typically done using a combination of chemical cleaning agents and mechanical scrubbing. After cleaning, the coil is rinsed and dried to prevent any residual moisture from causing corrosion. Once cleaned, the steel coil can undergo various treatments depending on its intended use. One common treatment is pickling, which involves immersing the coil in an acidic solution to remove impurities and scale. This process helps to improve the surface finish and prepares the steel for further processing. After pickling, the coil may be subjected to cold rolling, a process that reduces its thickness and improves its dimensional accuracy. Cold rolling involves passing the steel through a series of rollers at room temperature, gradually reducing its thickness and increasing its strength. This process also improves the surface finish of the steel coil. In some cases, the steel coil may undergo additional heat treatment processes, such as annealing or tempering. Annealing involves heating the coil to a specific temperature and then slowly cooling it, which helps to relieve internal stresses and improve its mechanical properties. Tempering, on the other hand, involves reheating the coil to a lower temperature and then cooling it rapidly. This process enhances the strength and toughness of the steel. Once the desired processing and treatments are complete, the steel coil may be coated or painted to provide additional protection against corrosion or to enhance its aesthetic appearance. Coating processes can include hot-dip galvanizing, electroplating, or applying organic coatings such as paint or powder coatings. Finally, the processed and treated steel coils are typically cut into specific sizes or shapes based on customer requirements. This can be done using various cutting methods such as shearing, slitting, or sawing. Overall, the processing and treatment of steel coils involve a combination of cleaning, pickling, rolling, heat treatment, coating, and cutting processes. These steps are carefully carried out to ensure the quality, strength, and suitability of the steel for its intended applications.

- Q: I have a white gold engagement ring, and to be special I thought I'd get a plain band from Tiffany's--in stainless steel. Can stainless steel be worn with white gold or will there be a difference in the color or texture? I'm not planning on getting them soldered together, but I don't want it to be noticeable that they are different metals. Does anyone have experience in this subject?

- I didn't know Tiffany's sold stainless steel rings. I think the colour might match, but the texture wouldn't really (from looking at all the stainless steel around my kitchen. The only way to know for sure is to go to Tiffany's and try it on with your ring. Why not consider a white gold band from Tiffany's? I don't know what the price difference would be on that. But you can get a white gold for around $250 from TCo.

- Q: What are the common welding techniques used for steel coils?

- The common welding techniques used for steel coils include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). SMAW, also known as stick welding, is a manual welding process where an electric current is used to create an arc between the welding electrode and the base material. The electrode is coated with a flux material that provides a shielding gas to protect the weld from atmospheric contamination. This technique is versatile and can be used for both thick and thin steel coils. GMAW, commonly referred to as MIG (metal inert gas) welding, is an automated process that uses a continuous wire electrode and a shielding gas to protect the weld area. The electrode is fed through a welding gun, and an electric current creates an arc between the wire and the base material. This technique is fast and efficient, making it suitable for high-volume production of steel coils. FCAW is a variation of GMAW that uses a tubular electrode filled with flux instead of a solid wire. The flux provides a shielding gas and also releases additional fluxing agents to protect the weld from impurities. FCAW is often preferred for welding thicker steel coils as it provides better penetration and higher deposition rates. In addition to these techniques, other welding methods like laser welding and electron beam welding can also be used for specific applications in steel coil manufacturing. These techniques offer precise and high-quality welds but are typically more expensive and require specialized equipment. Overall, the choice of welding technique for steel coils depends on factors such as the thickness of the material, production volume, and specific requirements of the end product.

- Q: Can steel coils be used in corrosive environments?

- Yes, steel coils can be used in corrosive environments. However, it is important to select the appropriate type of steel and implement suitable protective measures such as coatings or galvanization to prevent corrosion.

- Q: What are the different methods of roll forming steel coils?

- There exists a variety of techniques for roll forming steel coils, each possessing distinct features and uses. Some prevalent methods encompass: 1. Conventional Roll Forming: This technique, widely employed, involves gradually shaping a continuous steel strip into the desired profile by passing it through a series of rollers. It offers high precision and repeatability, making it ideal for manufacturing intricate shapes and profiles. 2. Pre-Punch and Cut: With this method, the steel strip is pre-punched with holes or slots before undergoing roll forming. This facilitates easier cutting and shaping during the forming process, enhancing efficiency and reducing waste in specific applications. 3. Post-Punch and Cut: Similar to pre-punching and cutting, this method adds holes or slots after the roll forming process. It provides greater flexibility in creating customized shapes and designs since the holes can be precisely placed as required. 4. Post-Forming: On certain occasions, the steel strip is initially roll formed into a basic shape or profile, which is then further manipulated or formed. This approach allows for additional customization and enables the creation of more intricate geometries. 5. Progressive Roll Forming: This technique involves continuously passing the steel strip through a series of rollers, with each roller gradually adding a distinct feature or forming a specific part of the final profile. Progressive roll forming is commonly utilized for lengthy, continuous profiles with repetitive shapes. 6. Incremental Roll Forming: In this method, the steel strip is incrementally shaped by means of small movements of the rollers. It provides greater flexibility in shaping complex profiles and proves particularly useful for producing prototypes or low-volume production runs. Ultimately, the selection of a roll forming method depends on the specific requirements of the application, such as the desired shape, complexity, precision, and production volume. Each method presents its own advantages and limitations, and manufacturers typically choose the most suitable technique based on these factors.

- Q: My mother is in a weilding class, and today she accidentally welded Galvanized Steel. She doesn't feel good and she wants to know what the symptoms are for Galvanized Poisoning from breathing in the Fumes. Please help, I am worried for her.

- i have a dog with a galvanized chain on her neck ''for looks'' can she get even the slightest harmful effect from it being on her 24/7?

Send your message to us

Cold rolled steel coils jsc270c from china supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 62450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords