CNBM Seamless Steel Pipe Hot selling With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DETAILS

1.Structure of Seamless Steel Pipe Description:

A large amount of Seamless Steel Pipes is offered to the clients at cost effective rates. These pipes are extremely durable, resistant to corrosion and have high tensile strength. Our pipes are used in nuclear plants, power plants, refineries and construction industry across the country. Furthermore, we are capable of providing these seamless pipes to the clients in bulk quantity.

2.Main Features of the Steel Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3.Packaging & Delivery:

| Packaging Details: | Seaworthy packages, bundles wrapped with strong steel strip |

| Delivery Detail: | 15-30 days after received 30% TT |

4.Seamless Steel Pipe Specification:

| Standard: | GB, DIN, ASTM,ASME, ASTM A106-2006, ASTM A53-2007 |

| Grade: | 10#,20#, 45#, 16Mn |

Thickness: | 8 - 33 mm |

| Section Shape: | Round |

| Outer Diameter: | 133 - 219 mm |

| Place of Origin: | Shandong, China (Mainland) |

| Secondary Or Not: | Non-secondary |

| Application: | Hydraulic Pipe |

| Technique: | Cold Drawn |

| Certification: | API |

| Surface Treatment: | factory state or painted black |

| Special Pipe: | API Pipe |

| Alloy Or Not: | Non-alloy |

| Length: | 5-12M |

| Outer Diameter: | 21.3-610mm |

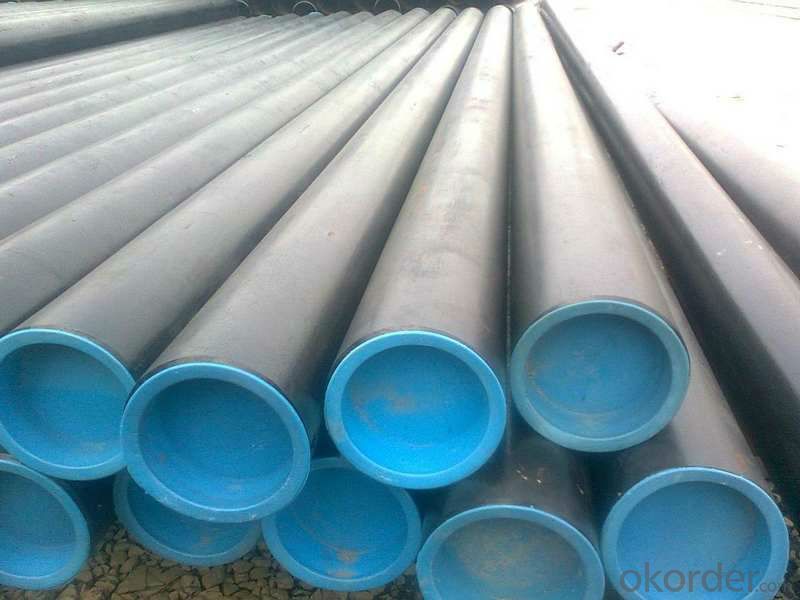

5.Product pictures

6.FAQ of Seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust.

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: What are the common applications of steel pipes in the water distribution system?

- Steel pipes are commonly used in water distribution systems for various applications such as transporting water from treatment plants to homes, buildings, and industries, as well as for underground water mains and fire hydrant systems.

- Q: How are steel pipes used in the infrastructure development?

- Steel pipes are widely used in infrastructure development for various purposes such as water supply, sewage systems, gas pipelines, and transportation of oil and natural gas. They provide a durable and efficient solution for the construction of underground and aboveground infrastructure, ensuring the safe and reliable transportation of fluids and gases. Steel pipes are also used in the construction of bridges, buildings, and other structural components, as they offer strength, versatility, and resilience to withstand harsh environmental conditions.

- Q: How long do steel pipes typically last?

- Steel pipes typically have a lifespan of 50 to 100 years, depending on various factors such as the quality of the steel, installation conditions, maintenance, and exposure to corrosive elements.

- Q: Are steel pipes suitable for use in pharmaceutical industries?

- Yes, steel pipes are suitable for use in pharmaceutical industries. Steel pipes are known for their durability, strength, and resistance to corrosion. These qualities make them ideal for transporting chemicals, gases, and liquids safely and efficiently within pharmaceutical facilities. Additionally, steel pipes can be easily cleaned and sanitized, ensuring the maintenance of high hygienic standards required in the pharmaceutical industry.

- Q: What is the bending strength of steel pipes?

- Steel pipes have the ability to withstand bending forces without breaking or permanently deforming, which is known as their bending strength. This strength can vary depending on factors like the type of steel, the grade of steel, the diameter and thickness of the pipe, and the manufacturing process. Steel pipes are highly durable and strong, making them suitable for many different uses. The bending strength of steel pipes is typically measured by the maximum bending moment or stress that the pipe can handle without failing. Engineers and manufacturers determine the bending strength of steel pipes using various testing methods, such as three-point or four-point bending tests. These tests involve applying a known force or moment to the pipe and measuring its deflection or stress response. The bending strength of steel pipes can also be affected by mechanical properties like yield strength, tensile strength, and elongation. These properties determine the overall strength and ductility of the steel, which are crucial for its bending strength. It's important to note that the bending strength can vary depending on the specific application and the load conditions. For instance, pipes used in structural or load-bearing applications may require higher bending strength than pipes used for plumbing or conveyance purposes. In conclusion, the bending strength of steel pipes is determined by factors such as the type of steel, the grade of steel, the diameter and thickness of the pipe, and the manufacturing process. Testing methods and mechanical properties are used to assess the bending strength of steel pipes, ensuring they are suitable for different uses and load conditions.

- Q: What is the maximum pressure that steel pipes can withstand?

- The maximum pressure that steel pipes can withstand depends on various factors such as the pipe's diameter, thickness, quality, and intended application. However, steel pipes are known for their high strength and durability, allowing them to withstand significant pressure.

- Q: What is the difference between hot-dipped galvanized and electro-galvanized steel pipes?

- Both hot-dipped galvanized and electro-galvanized steel pipes undergo a galvanization process to protect them from corrosion. However, there are distinct differences between the two methods. Hot-dipped galvanized steel pipes are immersed in molten zinc, resulting in a thick zinc coating on the steel's surface. This creates a durable and long-lasting barrier against corrosion. The thickness of the zinc coating varies, but it is generally thicker than that of electro-galvanized steel pipes. In contrast, electro-galvanized steel pipes are coated with a thin layer of zinc through an electroplating process. This involves passing an electric current through the pipes while they are submerged in a zinc solution. The zinc particles are then deposited onto the steel's surface, creating a thin and uniform protective layer. One key difference is the thickness of the zinc coating. Hot-dipped galvanized steel pipes have a thicker and more robust coating, making them suitable for harsh environments or exposure to corrosive materials. Another distinction is the appearance of the pipes. Hot-dipped galvanized steel pipes typically have a dull grayish finish, while electro-galvanized steel pipes have a smoother and more polished look. In terms of cost, electro-galvanized steel pipes are generally more economical because the electroplating process requires less labor and zinc. Ultimately, the choice between hot-dipped galvanized and electro-galvanized steel pipes depends on the specific application and desired level of corrosion resistance. Hot-dipped galvanized steel pipes are typically used in demanding environments, while electro-galvanized steel pipes are suitable for less corrosive applications where cost-efficiency is important.

- Q: Are steel pipes suitable for use in food processing industries?

- Yes, steel pipes are suitable for use in food processing industries. Steel pipes are highly durable, resistant to corrosion, and can withstand high temperatures and pressures, making them ideal for transporting various food products and fluids. Additionally, steel pipes are easy to clean, maintain hygiene standards, and comply with food safety regulations, making them a reliable choice for the food processing industry.

- Q: How do you prevent steel pipes from freezing in cold climates?

- One way to prevent steel pipes from freezing in cold climates is by insulating them with materials such as foam insulation or heat tape. This helps to maintain the temperature of the pipes and prevents them from freezing. Additionally, ensuring that all cracks or openings in the walls or foundation where the pipes are located are sealed can also help in preventing the pipes from freezing.

- Q: What is the difference between steel pipe and aluminum pipe?

- The main difference between steel pipe and aluminum pipe lies in their composition and physical properties. Steel pipes are primarily made of iron and carbon, with other elements added to enhance their strength and corrosion resistance. On the other hand, aluminum pipes are made entirely of aluminum, which is a lightweight and highly corrosion-resistant metal. One significant distinction between steel and aluminum pipes is their weight. Steel is a denser material compared to aluminum, meaning that steel pipes are generally heavier and sturdier. This characteristic makes steel pipes suitable for applications requiring higher structural strength and load-bearing capabilities. Aluminum pipes, on the other hand, offer distinct advantages due to their lightweight nature. They are around one-third the weight of steel pipes, making them easier to handle, transport, and install. This lightweight property also makes aluminum pipes more suitable for applications where weight reduction is crucial, such as in aerospace and automotive industries. Another crucial aspect to consider is corrosion resistance. Steel pipes are prone to rusting and corrosion, especially when exposed to moisture or corrosive environments. To combat this, steel pipes are often coated with protective layers or galvanized to enhance their resistance to corrosion. Aluminum pipes, on the other hand, have excellent natural corrosion resistance due to the formation of a thin layer of aluminum oxide on their surface. This oxide layer acts as a protective barrier, preventing further corrosion and degradation. Cost is another factor to consider when comparing steel and aluminum pipes. Steel pipes are generally more cost-effective compared to aluminum pipes, primarily due to the lower cost of raw materials and manufacturing processes involved. However, it is essential to consider the specific requirements and durability needed for the intended application, as the long-term maintenance costs and lifespan of steel and aluminum pipes may vary. In summary, the difference between steel and aluminum pipes can be summarized based on their weight, strength, corrosion resistance, and cost. Steel pipes are heavier, stronger, and more prone to rusting and corrosion but are generally more cost-effective. Aluminum pipes are lightweight, corrosion-resistant, and costlier but offer advantages in weight reduction and specific applications where corrosion resistance is crucial. Ultimately, the choice between steel and aluminum pipes depends on the specific needs of the project and the desired properties for optimal performance.

Send your message to us

CNBM Seamless Steel Pipe Hot selling With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords