CNBM 304/316/430/201 stainless steel sheet/plate with best price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,the description of the 304/316/430/201 stainless steel sheet/plate with best price

2,Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

3, related peoducts show

4,Speciality and advantages:

1. Our company has been dedicated to producing stainless steel seamless pipe since 2003, owning complete producing technology and abundant managing experience.

2. The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill: Walsin Steel and Yongxing Steel.

3. We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

4. We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

5. Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

6. The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

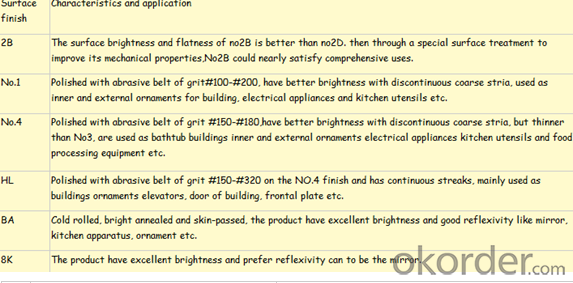

7. The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

5,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

3. Q: What is the application of 400 series stainless steel?

A: 410S stainless steel and 430 stainless steel are widely used for: kitchenware, tableware, cutleries, stainless steel pots, plates & bowls, sinks, gas stove, disinfection cabinet, household appliances, construction decorations etc. 409L stainless steel is usually used for exhaust pipe.

- Q: Can steel sheets be formed into complex shapes?

- Yes, steel sheets can be formed into complex shapes through various processes such as bending, rolling, and pressing.

- Q: Can steel sheets be used in corrosive environments like saltwater?

- Steel sheets are capable of being used in corrosive environments, such as saltwater. However, their suitability for such conditions depends on the type of steel and the level of corrosion resistance it provides. Stainless steel, for instance, possesses a high resistance to corrosion and is commonly utilized in marine and saltwater settings. This type of steel contains chromium, which creates a protective layer on its surface, shielding it from reacting with the saltwater. Other varieties of steel, like carbon steel, may also be employed in saltwater environments, but they necessitate additional protective coatings or treatments to prevent corrosion. Ensuring the durability of steel sheets in corrosive environments like saltwater requires regular maintenance and proper care.

- Q: Can the steel sheets be used for insulation purposes?

- No, steel sheets are not typically used for insulation purposes. Steel is a highly conductive material, meaning it transfers heat and cold very easily. This makes it unsuitable for insulation, as it would not effectively prevent the transfer of thermal energy. Insulation materials, on the other hand, are specifically designed to reduce heat transfer and improve energy efficiency in buildings and other structures. Common insulation materials include foam, fiberglass, and cellulose, which have much higher resistance to heat flow compared to steel.

- Q: Can steel sheets be used for manufacturing automotive parts?

- Yes, steel sheets can be used for manufacturing automotive parts. Steel sheets are widely used in the automotive industry due to their strength, durability, and cost-effectiveness. They can be easily formed, welded, and shaped into various automotive components such as body panels, chassis parts, and structural elements.

- Q: Can steel sheets be used for clamps or fasteners?

- Steel sheets alone cannot function as clamps or fasteners; nonetheless, they possess the potential to be transformed into such components. By cutting, shaping, and manipulating steel sheets, one can manufacture a range of clamps and fasteners, including brackets, plates, or strips. These manufactured components offer strength, durability, and secure attachment, making them suitable for various applications. Hence, while steel sheets in their original form cannot serve as clamps or fasteners, they can be utilized to create the necessary components for these purposes.

- Q: What are the dimensions of steel sheets?

- The dimensions of steel sheets can vary depending on the specific requirements and applications. However, commonly available steel sheets come in standard sizes such as 4 feet by 8 feet or 5 feet by 10 feet. Additionally, steel sheets can be found in various thicknesses ranging from thin gauges (e.g., 28 gauge) to thicker options (e.g., 16 gauge).

- Q: Are steel sheets suitable for manufacturing water pipes?

- Yes, steel sheets are suitable for manufacturing water pipes. Steel is a durable and strong material that can withstand high pressure and corrosion, making it an ideal choice for water pipes. Steel sheets can be easily formed and welded together to create seamless pipes that are resistant to leaks. Additionally, steel pipes have a long lifespan and require minimal maintenance, making them a cost-effective option for water pipe manufacturing.

- Q: Can steel sheets be used in agricultural applications?

- Yes, steel sheets can be used in agricultural applications. They are often used for building structures such as barns, sheds, and fences. Steel sheets provide durability, strength, and protection against weather conditions, making them suitable for various agricultural needs.

- Q: How are steel sheets tested for quality?

- To ensure compliance with required standards, various methods are employed to test the quality of steel sheets. Among these methods, the tensile strength test is commonly used. This test gauges the steel sheet's ability to withstand stress before breaking, thus determining its durability and reliability in different applications. Another significant test is the hardness test, which measures the steel sheet's resistance to indentation or scratching. Specialized tools like Brinell or Rockwell hardness testers are utilized for this purpose. The hardness test aids in assessing the steel sheet's capacity to endure wear and tear, making it suitable for specific applications. The thickness of the steel sheet is also examined using a micrometer or ultrasonic thickness gauge to ensure it meets the necessary specifications. This is crucial as the thickness directly impacts the sheet's strength and ability to withstand external forces. Furthermore, visual inspection is carried out by trained professionals to identify any surface defects such as cracks, pits, or corrosion. Through meticulous examination, any irregularities compromising the steel sheet's quality can be detected. Chemical composition analysis is another pivotal test that determines the presence and proportion of various elements in the steel sheet. Spectrometry or X-ray fluorescence techniques are employed to ensure the steel sheet meets the desired chemical requirements. Moreover, steel sheets may undergo additional tests such as impact testing, bend testing, and fatigue testing to evaluate their performance under specific conditions. These tests replicate real-world scenarios and assess the steel sheet's ability to withstand anticipated loads and stresses. In conclusion, steel sheets are subjected to rigorous quality testing to meet the necessary standards and provide customers with reliable and durable products. These tests enable manufacturers to identify potential flaws or defects, allowing them to rectify any issues and deliver high-quality steel sheets to the market.

- Q: Are steel sheets susceptible to rusting?

- Yes, steel sheets are susceptible to rusting if they are not adequately protected or exposed to moisture and oxygen.

Send your message to us

CNBM 304/316/430/201 stainless steel sheet/plate with best price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords