Ceramic Filter Plate for Alumina Making Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Foam Filter for Alumina Making Industry

Composite of Ceramic Foam Filter for Alumina Making Industry

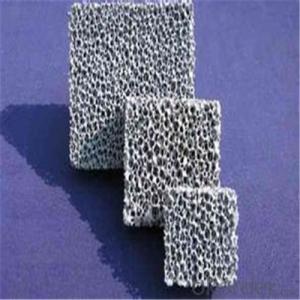

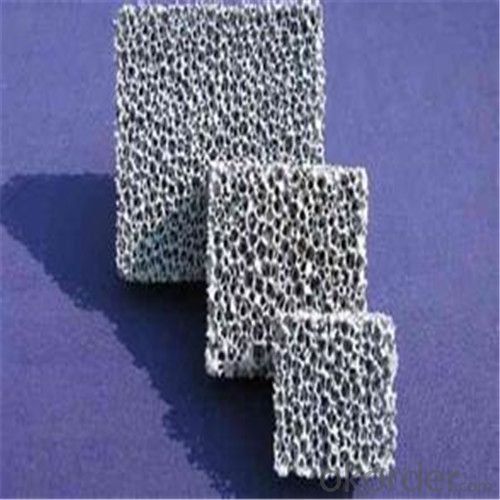

Ceramic Foam Filter is developed as a new type molten metal filters to decrease casting flaw in recent years. Foamed ceramics have the characters of light weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, chemical corrosion resistance and high temperature stability in molten metal. With the distributing pores net structure, they are able to increase the surface areas, and absorb the sinter, the liquid metal becomes more pure, waster quality problems such as sand pore and air pore are much less and the cast quality becomes much better.

Advantages of Ceramic Foam Filter for Alumina Making Industry:

Precise Dimension Tolerance

High Mechanical Strength

Chemical Stability and Corrosion-resistance for molten aluminum.

Phosphate-free, No Pollution for Environment

Purifying Liquid Aluminum, Improving Quality

Reduce Defects

Reduce Cost

Increase Yield Rate

Easy to Use

Size from 40-600mm available.

Ceramic Foam Filter for Alumina Making Industry Images

Specification of Ceramic Foam Filter for Alumina Making Industry:

Item | Unit | Alumina Foam Filter | Sic Foam Filter | Zirconia Foam Filter |

Bore Density | ppi | 10~80 | 10~60 | 10~40 |

Porosity | % | 80~90 | 80~90 | 80~90 |

Max.working Temperature | °C | 1100 | 1550 | 1700 |

Bending Strength | Mpa | 0.6 | 0.7 | 0.8~1.0 |

Compression Strength | Mpa | 0.7 | 0.8 | >1.2 |

Thermal Shock Resistance | times/1100°C | >6times | >6times | >6times |

SiC | % |

| ≥60 |

|

Al2O3 | % | ≥85 | ≤30 |

|

SiO2 | % | ≤15 | ≤10 |

|

ZrO2 | % |

|

| ≥95 |

Others | % |

|

| ≤5 |

application |

| Alumina and Alumina Alloy Non-ferrous | Grey Iron, Ductile Iron | Steel casting |

FAQ of Ceramic Foam Filter for Alumina Making Industry

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q9:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

- Q: Working principle, ultrasonic trouble and troubleshooting of ceramic filter

- The shape and mechanism of the ceramic filter are similar to those of the disc vacuum filter, but the filter media are different. The filter medium of ceramic filter is the ceramic filter plate, it can produce the micro capillary effect and capillary force in micropores is higher than the general vacuum applied force, so that the pores keep full of liquid state, so no matter what the circumstances, the air does not pass through the ceramic filter plate, so that the ceramic filter solid-liquid separation of low energy consumption, and high vacuum.

- Q: How many degrees does the ceramic filter melt?

- Alumina made from tabular corundum can be used over 1800 degrees!SiC if there is atmosphere, protection will be higher, there is no atmosphere protection, because the existence of oxidation, generally not more than 1600.Corundum, mullite, 1750 degrees small meaning.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- 50nm refers to the nominal pore size, but it does not mean that the holes in the ceramic membrane are 50nm, but the approximate number of holes. The size of the pores may be between 40~60 and 45 to 55nm. Generally introduced, annotated range, you can also own to detect.

- Q: What are the materials that make up the ceramic mold?

- Ceramic membrane, also known as CT film, is one of the solid membrane, the earliest by Japan's large Japanese printing company and Toyo ink company in 1996, the introduction of the market. The ceramic coating is mainly A12O3, Zr02, Ti02 and Si02 of inorganic materials such as porous membrane preparation, the pore size of 250mm. Has good chemical stability, acid resistance, alkali resistance, solvent resistance, high mechanical strength, can reverse flushing: anti microbial ability: high temperature, narrow pore size distribution, higher separation efficiency characteristics, has been widely used in food industry, biological engineering, environmental engineering, chemical industry, petroleum chemical industry, metallurgy industry etc. The market sales, with an annual growth rate of 35% growth. Compared with plastic products of ceramic membrane with similar high cost, but also has many advantages, it is hard to withstand strong, durable, not easy to have chemical resistance village, invasive and high temperature liquid cleaning liquid has a stronger ability to resist, its main drawback is the price expensive. _ complex manufacturing process

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- CleanThe cleaning of ceramic filter is divided into two parts: reverse flush cleaning (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board.Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure.Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.).

- Q: The working principle of ceramic filter

- Based on the work principle of ceramic filter function of the capillary, by using porous ceramic as filter media, a large number of small capillary action with solid-liquid separation equipment design principle using microporous ceramic disc filter in negative pressure, working conditions, characteristics of the microporous ceramic filter plate with its unique water impermeable, extraction of ceramic filter plate and external vacuum cavity the differential pressure tank suspension material under the action of negative pressure adsorption in the ceramic filter plate, solid material can not through the microporous ceramic filter plate is retained on the surface of the ceramic plate, and the liquid due to the hydrophilic effect of vacuum pressure difference and the ceramic filter plate is passed into the gas-liquid distribution device (vacuum barrel) efflux or recycling so as to achieve the purpose of solid-liquid separation.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- The vacuum degree of the ceramic filter is normal at about -0.08MPa. Under normal circumstances, the water content of the filter cake treated with a ceramic filter is about 10%, and the moisture content of the tail filter cake is about 15%. The water content of the filter cake increases with the increase of water content in the ceramic filter. I analyze the reasons from two aspects.

- Q: Does the ceramic factory use hydrochloric acid?

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Can be washed with chromic acid lotion. The effect is better

- Q: What are the functions of honeycomb ceramic filters?

- At present, it is widely used in metallurgy, foundry industry, metal melt filtration, using mullite (cordierite) ceramic materials

Send your message to us

Ceramic Filter Plate for Alumina Making Industry

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords