Ceramic Fiber Textiles Square Braided Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

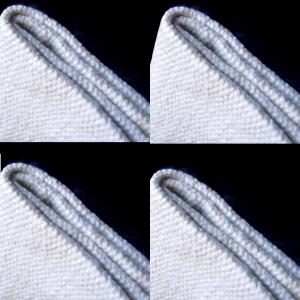

Ceramic fiber square braided packing is dense, resilient, high

performance ceramic fiber material fabricated from E-glass or

stainless steel wire 304 or 310 inserted ceramic fiber yarn which

braided around a core of ceramic fiber cord to form a packing in

square section.

Product Characteristics

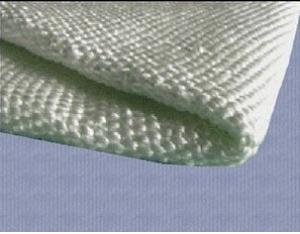

Ceramic fiber packing is made of high quality ceramic fiber woven.

Ceramic fiber Braided rope products are available in round and square form and produced by plaiting ceramic

fiber yarns around a central ceramic fiber core, resulting in a high strength, high density product with low

compressibility. Each yarn is reinforced with a single filament glass fiber or alloy wire depends on its work

temperature requirement. Those products are especially recommended for heavy duty applications.

Our ceramic fiber rope products are specifically designed and developed with temperature use limits from

450°C to 1000°C for thermal protection in low, medium, and high-temperature ranges.

Product Application

Ceramic Fiber Packing is suitable for high temperature , high pressure machines, pumps , valves, sealing

equipment : metal processing , boiler doors, door temperature , high temperature , high pressure machines,

pumps, valves industry ; can be widely used in the chemical, power, paper , food, pharmaceutical media , etc. ;

cleansing fluid or paste , salt , lotions , oils, hydrocarbons, solvents , paper pulp .

Physical Property

Pressure | 2-40 | Rotary Pump | 2 | M Pa *10 bar |

Reciprocating Pump | 2 | |||

Valve | 10 | |||

Temperature | -40-1260 | °C | ||

Velocity | 2-8 | M/s | ||

Density | 0.7-0.9 | G/cm3 | ||

PH value | 4-11 | |||

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Aluminum silicate fiber module in the well sealed at the same time, the thickness of heat insulation protection cases, can be isolated from the transfer of hot air to the maximum, complete isolation is not possible, the total fiber trolley furnace as an example, long-term use temperature of one thousand degrees, in addition to the door is sealed by the ceramic fiber packing do seal

- Q: Is everybody's ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..

- Q: Can ceramic fibers be spun?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

- Q: What are the uses of ceramic fiber blankets?

- The ceramic fiber blanket has a strong resistance to wind erosion, and can be directly contacted with flame and high-speed airflow. Because of its excellent fire resistance, high temperature stability, high thermal shock resistance, low heat capacity and high temperature conditions, high compressive strength.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- High temperature ceramic fiber cloth is made of ceramic fiber cotton, E-glass filament, high temperature resistant stainless steel alloy wire with a special process, high strength, good flexibility, high machinability, not only has high temperature heat insulation performance, has the flexibility of common textiles.

- Q: What are the differences between digital textile printing ink and printing ink?

- 3. acid ink:Suitable for jet printing of silk, wool and nylon;4. coating ink:Suitable for direct printing of all textiles.

- Q: What are the man-made fibers polluting the environment?

- Fiber (Fiber): a fine, soft filament formed by certain mechanical processes (traction, stretching, shaping, etc.) of a polymer. Fiber has a large elastic modulus, small deformation, high strength, high crystallization capacity, small molecular weight, usually tens of thousands of.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- 1. appearance. The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.2. density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.3. thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.4. stand erect. Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. Ceramic fiber cloth is like the fabric used in our 5. lives. It's soft and doesn't stand upright.6. tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: Which is better, ceramic fiber or spray velvet?

- Ji'nan Huolong thermal ceramics limited liability company to help you analyze: thrown silk and spray cotton, which is better? Which process is more suitable for producing carpets? Fire dragon energy saving from the technical point of view is as follows:1, fiber diameter: rejection fiber more coarse, rejection filament fiber is generally 3.0-5.0 mu m, spinneret fiber is generally 2.0-3.0 mu m;2, the length of fiber yarn: rejection fiber longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;3, the coefficient of thermal conductivity: spray cotton fiber is lower than that of the thrown silk;4, the tensile and flexural strength: thrown silk because fiber thicker than that of spraying cotton;

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Organic glass comes from English Organic Glass. In recent years, in some areas the sheet is made of transparent plastic all are called organic glass, actually this is wrong, it refers to pure acrylic polymethylmethacrylate (PMMA) and the PMMA sheet material, called acrylic plate.

Send your message to us

Ceramic Fiber Textiles Square Braided Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords