Ceramic Fiber Blanket for Industrial Stove Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Blanket for Industry Stove Insulation

Composite of Ceramic Fiber Blanket for Industry Stove Insulation

Ceramic Fiber Blanket for Industry Stove Insulation is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Types of Ceramic Fiber Blanket for Industry Stove Insulation: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Blanket for Industry Stove Insulation also has difference, and they are suitable for different working temperatures.

Main Features of the Ceramic Fiber Blanket for Industry Stove Insulation

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Application of Ceramic Fiber Blanket for Industry Stove Insulation

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Heat treating furnace or intermittent(shuttle) kiln hot face lining

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

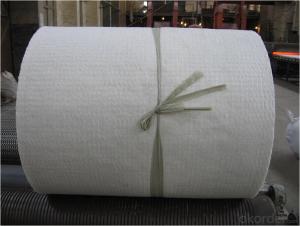

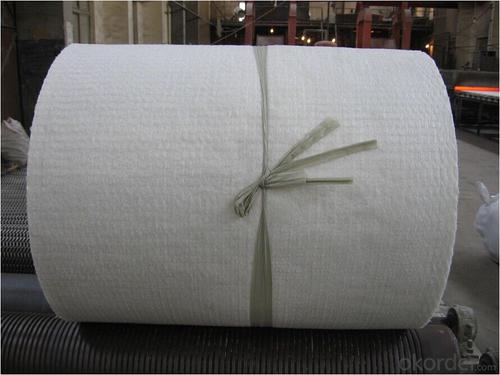

Ceramic Fiber Blanket for Industry Stove Insulation Images

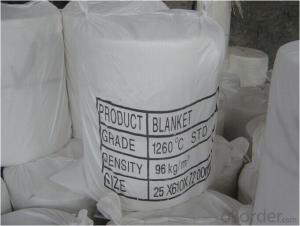

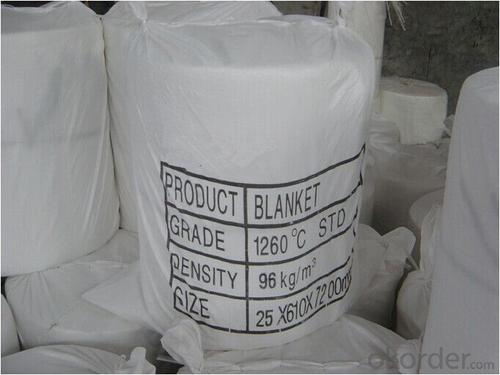

Ceramic Fiber Blanket for Industry Stove Insulation Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 64,96, | 64,96, | 64,96, | 64,96, | |

128,160 | 128,160 | 128,160 | 128,160 | ||

Shrinkage on heating (%) | -3 | -3 | -3.5 | 3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Blankt for Industry Stove Insulation

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

- Q: please anyone! if you know even a little about this, please answeri've been looking for some review of related literature about thisthank you!

- A rope made of twisted corn husks is a style of rope used by the Ioway people of prehistoric IowaManila ropes and Yarns are made from Abaca fibers, a plant which is a natural resource of the PhilippinesPhilippine Manila rope is the finest natural rope in the world compared to other natural rope productsSo Abaca rope is better than twisted cornhusk rope.

- Q: where can i find a light soft blanket?

- Try a micro-fiber blanket, they're awesome

- Q: I have to put my blanket and pillow up whenever she's around because she makes it all gooey with her sucking on itShe will bite me when shes playing but wants to play 24/7She doesn't listen to anything I say or respond to my disaplineIt's getting very aggravatingWill she outgrow this? What should I do?

- You know what sounds really gross but is acctually fabulous! Prune yogurt with All Bran buds in itIt's so good! Oh and good luck on your diet thingyI hope you don't die! :D

- Q: Our attic is unfinished (it's all 2x4's and insulation up there) and I am interested in exploring the attic for a small wiring projectUnfortunately, a number of the rooms in the house have large tray ceilings or vaulted ceilingsThis causes some problems when I am trying to move around in the attic, since I reach a point that I can't go beyond (the tray ceiling)There is no room to walk/crawl around it and essentially it looks like a big bump with insulation all over itAs far as I can see there are not any other entrances to the attic over the other side of the house, so I am at a lossI do not want to crawl on top of the tray since I would be crawling on insulation and for all I know the tray can not support any weight.I realize that without seeing the layout it may be difficult to respond, but i was wondering in general how people move around in attics that are above tray/vaulted ceilings? Are there any tricks?

- what is the use of the piece you want to coat? the best thing I can suggest with out knowing more is wet look by behr available at Home Depotyou get a high gloss look.

- Q: What is the material of ceramic fiber?

- Ceramic fiber is a fibrous and light fireproof material with such advantages as light weight, resistance to high temperature, good heat stability, low thermal conductivity and specific heat, resistance to mechanical shock, etc., thus being widely used in such industries as machinery, metallurgy, chemical industry, petroleum, ceramic, glass, electronics, etc.

- Q: Making little girl dressesNeed a fabric that is nearly wrinkle free.

- It depends on how much prep time you want to spendIf you have some time go for the LasagnaIt is one of my favoritesIf not then just go for the spaghetti.

- Q: Last week I had gastritisNever had it beforeExcruciating was the pain I had diarrhoea as wellWent to see the doctorI still get slight abdominal pains when, I guess, I eat the wrong foodNd advice from those who had this before or those in the medical professionWhat kind of food will help the healing and of what quantity shld I be taking it?

- After a severe attack like you had you need to eat Foods that are not irritating to the intestinesI have enclosed a list As a general rule, the grain and cereal foods at the top of this list make the safest, easiest, and most versatile soluble fiber foundations for your meals and snacksRice, Pasta and noodles, Oatmeal, Barley, Fresh white breads such as French or sourdough (NOT whole wheat or whole grain) Rice cereals, Flour tortillas, Soy, Corn meal, Potatoes, Carrots, Yams, Sweet potatoes, Turnips, Beets, Squash and pumpkins, Mushrooms, Chestnuts, Avocados (though they do have some fat), Bananas, Applesauce, Mangoes, Papayas (also digestive aids that relieve gas and indigestion) Please choose a baked-daily, high quality, preservative-free brandWhite bread does not mean WonderTake an acidolphilis capsule twice daily on an empty stomach to help get balance back into your intestinesDo not drink milk as it will cause further diarrhea .

- Q: The last days it has been snowing here (Holland)My car is covered with about 20 cm of fresh snowI don't need the car in about a few daysComing nights become cold with temps up to -15 degrees C.If snow is present on an ice floor it will grow thicker lots slowerSo, hence the question: My car is under 20cm of snow, coming nights are getting very cold (temps up to -15 C), is it better to leave the snow on my car?

- If your lettuce is still green and looks crisp, it is probably still good and safe to itI have managed to keep some heads of lettuce for over 3 weeks and they were perfectly good.

Send your message to us

Ceramic Fiber Blanket for Industrial Stove Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords