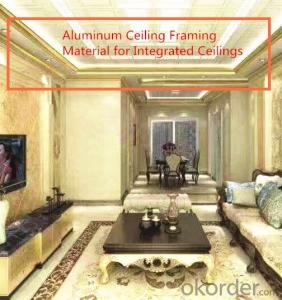

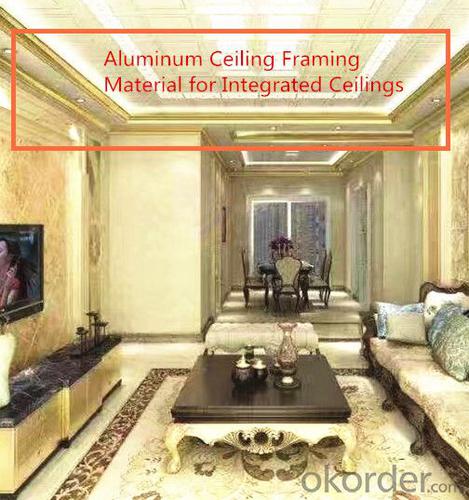

Aluminium Perforated Ceiling Singapore - Ceiling Framing Material for Integrated Ceilings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Introduction

As aesthetic values evolve, wood grain effect finishing is now becoming more and more popular in the fields of architectural decoration, furniture, electronics and home appliances. Wood grain effect finishing is a special powder coating process based on the latest technology in the surface finishing.

The wood grain finished aluminum profile is a perfect integration of the excellent aluminum properties with the natural appearance of natural resources such as wood, marble, etc. It is a wonderful combination of the state-of-the-art technology and aesthetics. The products have stable quality, appealing appearance and therefore a higher value of decoration.

2. Wood Grain Effect Features

(1). Materials:

can be transferred to all kinds of substrate shapes, including sheets.

(2). Effects:

The decorative effects of pictures, text and graphs, and all kinds of natural sceneries (such as wood, marble or granite grains) can be achieved through photographic technology.

(3). Aesthetic Value:

Patterns of the most precious woods, such as oak, chestnut, cherry and walnut, can be imitated.

(4). Durability:

Excellent weathering-resistance performance, durable in all kinds of applications.

(5). Cost Savings:

Maintenance free, will resume original effect simply by regular cleaning.

(6). Environmental Friendliness:

The special decoration needs can be realized without using wood; meanwhile the products can be recycled.

(7). Fields of Applications:

The wood effect can be applied to windows, furniture, components, appliances, transportation vehicles (airplanes, ships and cars) and other decorating materials. It can be furnished according to customer requirements

3. Chemical composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al |

6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

6061 | 0.4-0.8 | 0.70 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.15 | Rest |

6005 | 0.6-0.9 | 0.35 | 0.1 | 0.1 | 0.4-0.6 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

4. Mechanical property

Alloy | Temper | Tensile strength | Yield strength | Elongation |

6061 | T6 | ≥ 265Mpa | ≥ 245Mpa | ≥ 8% |

6063 | T5 | ≥ 160Mpa | ≥ 110Mpa | ≥ 8% |

T6 | ≥ 205Mpa | ≥ 180Mpa | ≥ 8% |

5. Anodized

Grade | Anodizing thickness | Hole scaling quality of oxide layer | |

Average thickness | Local thickness | P. Cr acid-erosion weight less method | |

AA10 | ≥10um | ≥8um | ≤30 mg/d m2 |

AA15 | ≥15um | ≥12um | |

6. Powder coating & wooden-grained

Coating thickness | Coating impress rigidity | Adhesive force of coating layer |

40-120um | Indentation hardness>80 | 0 grade

|

7.

Material | 6063,6060,6061,6005 |

Temper | T4,T5,T6 |

Surface treatment | Mill Finish,Anodized,Eletropharesis,Powder Coated, Wooden Finish, Polish |

Colour | Silver,Black,Red,Blue,or as required |

Length | ≤6m |

Shape | Round,Square,T-slot,or as per the drawings and samples |

Fabrication | cutting,drilling,punching,bending,etc |

Wall thickness | ≥0.5mm |

Package | inner plastic paper interleaving each piece profile,outer fixed by plywood, or as per your requirements |

- Q: 3DMAX in the aluminum slab ceiling how to do real? (In addition to using the map)

- No map, I really did not do. Do not map to do these things, like no PS do the same background. Even if you have the energy, but the computer can not afford ah

- Q: Aluminum slab ceiling and mineral wool board ceiling which is better and more expensive

- Aluminum slabs are usually used in home improvement market. Because it is generally used in the kitchen bathroom, when used the most important concern is the effect of oil and water. Aluminum slab plate, especially the roller coating of the durability effect is better mineral wool sheet is mainly used in the engineering market.

- Q: Magnet suction does not suck aluminum buckle plate?

- The magnet can attract a metal with a magnetic property. Iron, cobalt, nickel is a typical magnetic metal, so iron, cobalt, nickel can be attracted by the magnet; magnets can not attract non-magnetic metal and non-metallic, aluminum is non-magnetic metal, so aluminum and non-magnetic metal can not be Magnet attracted.

- Q: Aluminum plate: a decoration of the board with the plate, aluminum, not plastic!

- Glass glue is divided into acidic and neutral, neutral can be used to nail soft nail deduction, and then gently wipe with a hot towel on it, and if a good acid glass glue get more solid, or the old way, do not worry , To slowly get, do not use the blade, or metal tools (free of the surface of the bruised trouble)

- Q: What is the lamp to be used in the kitchen?

- Agree with the views of the upstairs, where you usually buy someone who has a matching ceiling of the main lights to see the size of your kitchen to set the size of the light

- Q: What is an aluminum honeycomb ceiling? Applied to the decorations of those places? What are the advantages?

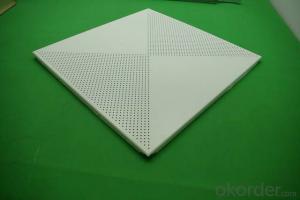

- From the bottom plate, panel and aluminum honeycomb core composite made. The panel is mainly made of high quality 3003H24 alloy aluminum plate or 5052AH14 high manganese alloy aluminum plate as the substrate, the panel thickness is 0.7-1.0mm fluorocarbon roller coating, the bottom plate thickness is 0.5-1.0mm, the total thickness is 10mm-25mm. Core material with hexagonal 3003H24-type aluminum honeycomb core, aluminum foil thickness 0.04-0.06mm, side length 5-6mm, with different design and demand for production. Add-ons. Can be configured with the size of lamps and ventilation equipment, sprinkler and all kinds of decorative pieces. Easy to decorate and disassemble, easy to clean, change the indoor interval feel more flexible. Reynolds aluminum honeycomb ceiling with a flat plate and perforated plate to choose from, perforated plate has a different proportion of openings and patterns. Can create a perfect sound absorption function.

- Q: Aluminum buckle plate and steel which is better

- Differences and better than plastic steel plate where: Plastic plate is still plastic, we all know, the chemical stability of plastic is far less than a class of aluminum metal, over time is prone to deformation, discoloration (in the fumes smoked more easily). As for keel: Should be used to deliver the keel. General sales according to the required distribution, iron keel also known as light steel keel, better than wood. Because not afraid of fire, not because of wet material deformation, not afraid of insects. And the installation is convenient, much easier than the wood keel. If the wood by the words, one is more flowers of wood money, the second is the effect is not good.

- Q: 0.4 mm aluminum plate quality is not very poor

- In general. The buckle is not the thickness. Mainly to see how workers work.

- Q: It is good for the film and the film

- Spraying metal products: Spraying metal ceiling is the use of domestic high-quality aluminum alloy plate as the substrate, the use of imported epoxy resin or polyester powder spray, the advanced electrostatic powder coating production line, so that epoxy resin or polyester powder through Thermosetting, under certain conditions to be fully reacted, converted into modified epoxy (that is, high polymer materials), so that the product surface to achieve smooth, anti-pollution and other characteristics.

- Q: 0.6 mm aluminum buckle plate is multiple

- Equal to 12.2 kg weight of a board.

Send your message to us

Aluminium Perforated Ceiling Singapore - Ceiling Framing Material for Integrated Ceilings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 1000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords