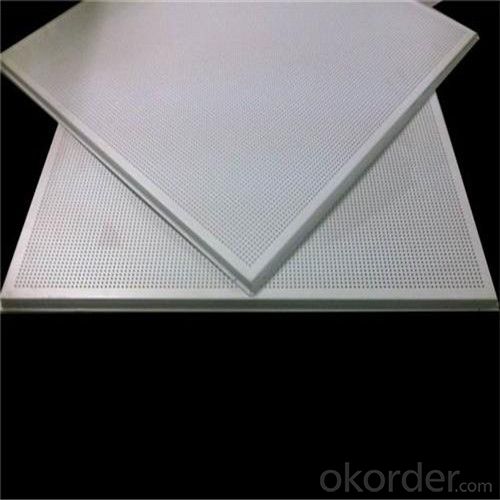

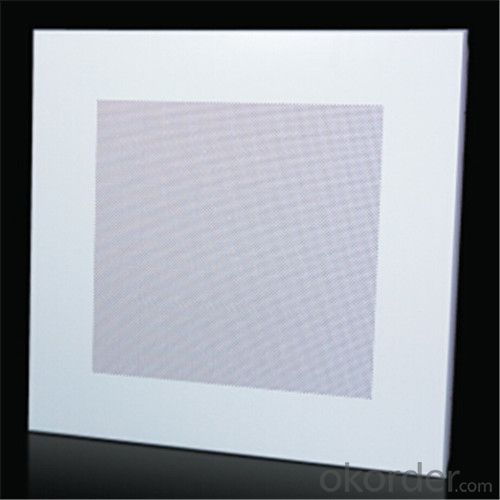

Aluminium Composite Panel Ceiling - Aluminium Ceiling Clip In Type Perforated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

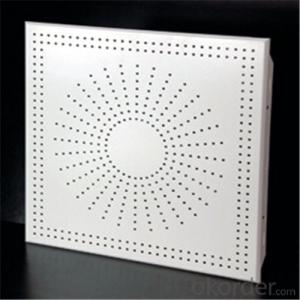

Our square ceiling series include:plan square ceilings,down-level ceilings,combination ceilings,perforated ceilings.

Application

Halls, Hospital, Offices and so on.

Features

1.Rgulated shape

2.Beauty

3.Elegance

4.Widen vision

5.Easy installation

6.Easy cleaning

Base material

Aluminum alloy ,the gread of aluminum alloy can be selected according to the actual requirements.

Type of surface

Surface venner:Power coating(ordinary power,polyester),rolling,laminating,metal anode oxidation treatment.Can be pore panel or punching panel according to the actual requirements.

Size:

595*595mm, 605*605mm

Thickness: 0.5mm,0.6mm,0.7mm

Features:

1.Aluminium material,fireproof,waterproof,soundproof

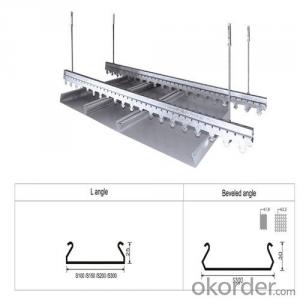

2.Suspended installation,won't harm the base ceiling

3.Flat non-trace,splicing seamless:

4.Each plate edge have screens orientation to ensure the ceiling smoothly and beautiful.

5.Plates joining together through by keel,which make splicing seamless and engineer cover,and moisture.

6.On the back of the ceiling with the sound-absorbing paper or cotton, make it has the best sound-absorbing function.

7.Suitable for indoor,such as office buildings, schools, hospitals,supermarket, channel, banks, etc.

Specification of aluminum ceiling clip in tiles 600X600

Clip-in | Size | Height | Thickness | Edge |

(mm) | (mm) | (mm) | ||

300*300 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

300*600 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

300*1200 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

400*400 | 1020/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

500*500 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

600*600 | 10/20/25 | 0.45-1.0 | Beveled Edge/Straight Edge | |

Lay-in | 275*275 | 8/10 | 0.45-1.0 | Straight Edge |

295*295 | 8/10 | 0.45-1.0 | Straight Edge | |

575*575 | 8/10 | 0.45-1.0 | Straight Edge | |

585*585 | 8/10 | 0.45-1.0 | Straight Edge | |

585*1185 | 8/10 | 0.45-1.0 | Straight Edge |

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: How about the quality of the ceiling

- While the metal ceiling aluminum plate is better, the current market is also divided into the following points: The first type of aluminum-magnesium alloy, which contains some of the manganese, the biggest advantage of the material is good antioxidant capacity, and because adding the right amount of manganese, the strength and stiffness to improve, is the best material ceiling. The second type of aluminum - manganese alloy, the strength and stiffness of the plate is slightly better than the aluminum - magnesium alloy, but the antioxidant capacity is slightly inadequate; The third type of aluminum alloy, the plate contains manganese, magnesium less, so its strength and stiffness are significantly lower than the aluminum-magnesium alloy and aluminum-manganese alloy, antioxidant capacity in general.

- Q: The ceiling who is responsible for the installation? Engineering team or selling ceiling business? Not an integrated ceiling, is the general aluminum plate hanging ceiling.

- Integrated ceiling is generally sold to sell the ceiling. Because the technical requirements are relatively high, the general construction team may not have this master. Ordinary aluminum plate hanging ceiling, you want to talk with the business, in general, is also selling the ceiling to install the master of the more experienced. Because the master of the business is to do this professional, what happened to have encountered.

- Q: There are long and rectangular, and square, they are what size?

- 300 * 300,300 * 450,300 * 600, these specifications of the aluminum buckle board with more, put out the effect of more beautiful fashion, and easy to fight modeling, long aluminum buckle in the bathroom ceiling is not recommended, Can be used in the tooling.

- Q: Exhibition hall ceiling aluminum grid 3d is how to do

- In fact, with the other curtain wall concealed works the same practice, concealed works will be closed after the invisible place to the supervision and acceptance, and confirmed on the acceptance can be, the glass curtain wall is basically covered by the part of the hidden layer of the hidden , The information around the electronic dog has.

- Q: How much is the price of an inch? Pack material

- According to the brand and thickness, specifications, etc. to determine, generally the cheapest also more than 60 yuan, the thickness of only 0.4mm less than.

- Q: Bathroom moisture is too heavy, I am afraid to use gypsum board will fall off, want to use aluminum buckle board, but the designer suggested that I use moisture gypsum board, we have no one know how to choose ah?

- Now home installation, then, are used more of the aluminum plate, durable time is also long Gypsum board easy to fall off, the use of time is not long, in exchange for not as good as the use of aluminum buckle plate cost-effective, but also save trouble

- Q: How to install the aluminum slab ceiling

- Aluminum slab ceiling ceiling is used in the decoration of a more material, its installation method is relatively simple, the specific construction methods: first in the original top with a hammer drilling, in the eye into the ceiling for the expansion of special expansion bolt and hanging, and then The aluminum buckle plate buckle on the hanging, the wall with a good angle aluminum ring, you can on the aluminum plate. To buy buckle board, not the same as the aluminum plate has a matching buckle and angle aluminum.

- Q: Home improvement aluminum plate thickness in the end is how much is considered good

- Because the buckle is the main decorative effect. There is no anti-wrinkle resistance and so on. As long as the formation of uniform, easy to install and maintenance on it. The actual decoration, to the building materials market at a glance.

- Q: Aluminum buckle board edge of this used to do

- Is used to fix the need to cut off the buckle to make the gap between the pinch and the edge of the minimum in the fight when the glass glue more beautiful look good, no cut on the need not directly on the line

- Q: Aluminum cords hanging around the ceiling how to fight glass glue

- Glass glue is now more suitable for bonding, blocking the gap of the material. Neutral glass gel is still very soft after the basic maintenance does not appear to remove the need to remove the aluminum plate when the card can not be unloaded and damaged buckle plate. Be sure to clear the neutral glass glue completely cured (about 7 days later) and then cut off the blade more convenient.

Send your message to us

Aluminium Composite Panel Ceiling - Aluminium Ceiling Clip In Type Perforated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords