Casting ductile iron manhole cover for mining made in Hebei Province

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Overview

Quick Details

Place of Origin:

Hebei, China (Mainland)

Brand Name:

CMAX

Model Number:

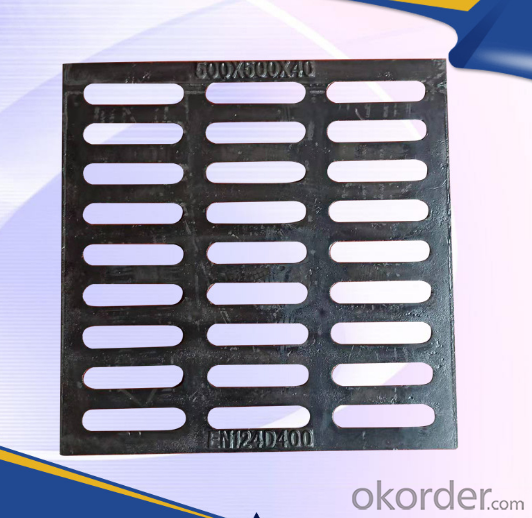

EN124 Standard

Application:

Industry

Material:

Iron

Dimensions:

Customer Required

Standard:

EN124 Standard

Process:

Casting. Deburring .Drilling .threading

Name:

Precision Die Casting Parts

Type:

Moulding Press

Certification:

ISO9001-2008

Color:

Original Color

Surface treatment:

Painting

Service:

OEM ODM

Product name:

OEM Products

Item:

OEM China Die Casting

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) |

| CCUC68HK | C250 | 500*700 | 600*800 | 60 |

| CCUC70HK | C250 | 600*600 | 700*700 | 50 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, endurable period (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film,

Delivery Detail: we will deliver your goods within 30 days after your purchasing of our goods.

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2.How about your time of delivery?

A:Within in 30 days after the order is concluded.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angleEspecially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: Domestic large steel castings factory which is better, recommend!

- At least spend money on research and development, then the quality should be all right.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: Casting parts have poor surface finish. What sand is used to make them?

- Now resin sand, coated sand and other processes are also very good surface.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: How to solve casting defect casting?

- Prevention methodReduce the gas in the metal liquid and oxidize the slag, improve the fluidity of the metal liquidIncrease pouring temperature and pouring speed, strengthen slag collection, slag block or bottom pouring bag, teapot ladle pouring, can not cut off when pouring, prevent the slag from blocking the nozzle, and cause the casting to breakIncrease the sprue and sprue height, increase the runner section area and the sprue number, and improve the filling speed and the metal hydrostatic headImprove the casting design and increase the thickness of the thin-wall part of the castingChange the pouring position and pouring system, the casting thin wall plane is located at the top and away from the gate, to prevent the filling of liquid metal splashing, eddy current, avoid metal stream in the casting thin sections or core support, cold iron, insert the confluence, when necessary, take horizontal vertical pouring cold or inclined castingIncrease the permeability of core and sand, strengthen the exhaust of mould, and the quantity of air outlet and riser should be enoughChange the size and location of the core, the inner cold iron, the core support, the internal cold iron, the insert should be no rust, no oil pollutionCheck the type, tight box, press the operation of iron is safe, to prevent running fire

Send your message to us

Casting ductile iron manhole cover for mining made in Hebei Province

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches