Castable Cement Refractory Cement For Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Castable Refractory for Fireplaces and Industrial Furnaces

Product Description:

Castable cement refractory is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by clients. Gunning castables use high purity raw materials and additives as the main material, and are made with superfine powder adding technology.

Product Features:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, and also excellent working ability. If should be used with the same material products.

Product Applications:

Widely used in various kiln linings, such as boilers, blast furnace hot blast stoves, heating furnaces, ceramic kilns, heat treatment furnaces, incinerators, re-circulating fluidized bed furnaces and chemical industry and construction industry furnaces.

Product Specifications:

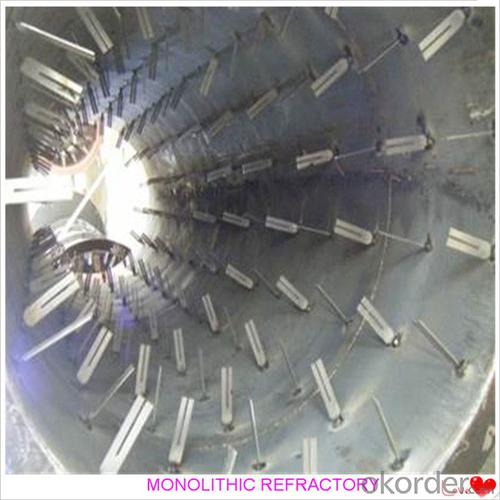

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: What are the quality control measures for monolithic refractories in the iron and steel industry?

- The quality control measures for monolithic refractories in the iron and steel industry include strict material selection, thorough testing of raw materials, regular inspection and maintenance of refractory linings, and continuous monitoring of performance during operation. Additionally, adherence to industry standards and specifications, implementation of quality management systems, and collaboration with suppliers and customers to address any quality issues are also important measures in ensuring the quality of monolithic refractories in the iron and steel industry.

- Q: How do monolithic refractories contribute to reducing emissions in iron and steel processes?

- Monolithic refractories play a crucial role in reducing emissions in iron and steel processes by providing superior insulation, increased energy efficiency, and improved control over the production process. These refractories are designed to withstand extreme temperatures and harsh conditions, effectively minimizing heat loss and reducing the need for excessive fuel consumption. By creating a highly insulated environment, monolithic refractories enable better temperature control, leading to optimized combustion and reduced emissions of greenhouse gases. Additionally, their high resistance to wear and corrosion helps prevent the formation of pollutants, thereby contributing to a cleaner and more sustainable iron and steel industry.

- Q: What are the key properties of ramming mixes used for monolithic refractory installations?

- The key properties of ramming mixes used for monolithic refractory installations are: 1. High thermal stability: Ramming mixes should possess high thermal stability to withstand the extreme temperatures and thermal cycling in refractory applications. This property ensures that the ramming mix remains intact and does not undergo significant structural changes under varying thermal conditions. 2. High density: Ramming mixes need to have a high density to provide good resistance against thermal conductivity. This property helps in minimizing heat loss and maintaining the desired temperature in the refractory lining. 3. Low porosity: Low porosity is essential for ramming mixes as it helps in reducing the penetration of molten metals or slag into the refractory lining. This property enhances the overall durability and longevity of the refractory installation. 4. Good mechanical strength: Ramming mixes should possess good mechanical strength to withstand the stresses and loads encountered during installation, as well as during the operation of the refractory lining. This property ensures that the ramming mix can resist any physical or mechanical damage, such as cracking or spalling. 5. Chemical resistance: Ramming mixes should exhibit excellent resistance to chemical attack from molten metals, slag, or corrosive gases. This property is crucial for protecting the refractory lining from chemical reactions and degradation, which can compromise its performance and lifespan. 6. Easy installation and workability: Ramming mixes should have good workability, allowing for easy installation and compaction. This property ensures that the mix can be easily shaped and rammed into place without excessive effort or time, facilitating efficient and effective refractory installations. 7. Controlled setting time: Ramming mixes should have a controlled setting time to allow sufficient time for proper placement and consolidation. This property ensures that the mix remains workable during installation but sets and hardens within a reasonable time frame, allowing for timely completion of the refractory lining. In summary, the key properties of ramming mixes used for monolithic refractory installations include high thermal stability, high density, low porosity, good mechanical strength, chemical resistance, easy installation and workability, and controlled setting time. These properties collectively contribute to the overall performance, durability, and longevity of the refractory lining in various high-temperature applications.

- Q: What are the factors influencing the choice of monolithic refractories for different furnace types?

- There are several factors that influence the choice of monolithic refractories for different furnace types. Firstly, the operating temperature of the furnace is a crucial factor as different monolithic refractories have different temperature resistance levels. Secondly, the type of material being processed in the furnace is important as certain materials may require specific refractories to withstand their corrosive or abrasive nature. Thirdly, the furnace design and its heating method also play a role in determining the suitable refractory material. Additionally, the thermal conductivity, thermal shock resistance, and mechanical strength of the refractory are considered to ensure optimal performance and durability. Finally, cost, availability, and installation requirements are factors that can influence the choice of monolithic refractories for different furnace types.

- Q: Can monolithic refractories be used for the lining of continuous casting tundishes and molds?

- Yes, monolithic refractories can be used for the lining of continuous casting tundishes and molds. Monolithic refractories are versatile and can be shaped or molded to fit the specific requirements of the tundish and mold lining. They offer excellent thermal shock resistance and high-temperature stability, making them suitable for the harsh conditions of continuous casting. Additionally, monolithic refractories have low porosity, which helps prevent the penetration of molten metal and promotes longer service life for the tundish and mold lining.

- Q: How do monolithic refractories mitigate heat loss in iron and steel operations?

- Monolithic refractories possess unique properties and composition that make them highly effective in reducing heat loss in iron and steel operations. Unlike other refractories, monolithic ones are made from a single, continuous material, making them resistant to cracks and gaps that could potentially allow heat to escape. One major advantage of monolithic refractories lies in their exceptional thermal conductivity and insulation properties. With their low thermal conductivity, they are able to effectively limit the transfer of heat from hot areas to cooler surroundings. This insulation characteristic helps maintain high temperatures within iron and steel operations, resulting in reduced heat loss to the environment. Another contributing factor to heat loss mitigation is the ability of monolithic refractories to form a tight seal with the metal structures they are applied to. They adhere well to surfaces and fill in any gaps or irregularities, creating a solid barrier against heat loss. By minimizing the possibility of heat escaping, these refractories ensure that the energy generated within the operations is utilized effectively. Additionally, monolithic refractories exhibit high resistance to thermal shock. In the iron and steel industry, rapid temperature fluctuations are common, which can lead to material deterioration and cracks. However, monolithic refractories possess the ability to withstand these temperature changes without compromising their structural integrity. This guarantees the longevity and effectiveness of the refractories in mitigating heat loss. In summary, monolithic refractories play a vital role in reducing heat loss in iron and steel operations through their excellent insulation, ability to form a tight seal, and resistance to thermal shock. These properties enable them to maintain high temperatures, optimize energy utilization, and enhance overall process efficiency.

- Q: What are the key properties of patching mixes used for monolithic refractory repairs?

- The key properties of patching mixes used for monolithic refractory repairs include high thermal conductivity, excellent adhesion, good workability, high strength, resistance to thermal shock, and suitable setting and drying times. These properties ensure effective repairs and long-lasting performance in high-temperature applications.

- Q: What are the key factors to consider when designing the lining system with monolithic refractories?

- When designing a lining system with monolithic refractories, there are several key factors that need to be considered. Firstly, the operating conditions of the system need to be thoroughly assessed. Factors such as temperature, pressure, and chemical composition of the materials being processed should be taken into account. This will help determine the appropriate type of monolithic refractories to be used. Secondly, the physical and mechanical properties of the refractories should be considered. These include factors like thermal conductivity, thermal expansion, and mechanical strength. The refractories should have properties that are compatible with the specific requirements of the system to ensure optimal performance and longevity. Thirdly, the installation method and techniques need to be carefully planned. The lining system should be designed in a way that allows for proper installation and ensures a tight seal to prevent any leakage or infiltration. The installation process should also take into account factors like curing time and temperature to ensure the refractories achieve their desired properties. Lastly, the cost and availability of the refractories should be considered. It is important to choose refractories that are cost-effective and readily available in the market. This will help ensure that any maintenance or repairs can be done efficiently without causing significant downtime or additional expenses. By considering these key factors, a well-designed lining system with monolithic refractories can be implemented, providing optimal performance, durability, and cost-effectiveness for the specific application.

- Q: What are the factors affecting the lifespan of monolithic refractories?

- The lifespan of monolithic refractories can be significantly affected by several factors. 1. Operating temperature is a critical factor. While monolithic refractories are designed to withstand high temperatures, prolonged exposure to extreme temperatures can cause thermal shock and lead to premature failure. 2. Thermal cycling, which refers to frequent temperature fluctuations, can also shorten the lifespan of monolithic refractories. The refractory material expands and contracts, creating stress that can result in cracking and degradation over time. 3. The chemical environment where the monolithic refractories are used plays a crucial role in their lifespan. Exposure to corrosive gases, acids, alkalis, or molten metals can cause chemical reactions that degrade the refractory material. 4. Mechanical stress, such as abrasion, impact, and vibration, can weaken monolithic refractories and reduce their lifespan. This is particularly important in industries with high mechanical activity, such as steelmaking or cement production. 5. Proper installation and regular maintenance are essential for maximizing the lifespan of monolithic refractories. Inadequate installation techniques or neglecting maintenance can result in weak joints, inadequate anchoring, or the growth of cracks, leading to premature failure. 6. The quality and composition of the monolithic refractory material greatly impact its lifespan. Higher-quality materials with better resistance to temperature, chemical attacks, and mechanical stress tend to have longer lifespans. 7. The design of the refractory lining and its engineering considerations, such as thickness, shape, and reinforcement, also influence the lifespan of monolithic refractories. A proper design can distribute stress more evenly, reduce thermal gradients, and improve overall performance and durability. 8. The way monolithic refractories are operated and handled can affect their lifespan. Factors such as rapid temperature changes, improper cooling or heating procedures, or excessive thermal cycling can all contribute to premature failure. In conclusion, various factors such as temperature, thermal cycling, chemical environment, mechanical stress, installation and maintenance practices, quality of refractory material, design and engineering considerations, and operating conditions all impact the lifespan of monolithic refractories. Proper management and consideration of these factors are essential for maximizing their lifespan.

- Q: How do monolithic refractories withstand the thermal cycling in aluminum smelting applications?

- Monolithic refractories are specifically designed to withstand the extreme thermal cycling conditions encountered in aluminum smelting applications. The unique properties of these refractories allow them to endure the rapid and repetitive heating and cooling cycles without significant damage or failure. One key feature of monolithic refractories is their excellent thermal shock resistance. This property enables them to withstand sudden temperature changes without cracking or spalling. During the aluminum smelting process, the refractories are exposed to extreme temperatures when molten aluminum is poured into the molds or when the molten metal comes in contact with the refractory lining. The refractories must be able to absorb and dissipate the heat rapidly to prevent thermal shock damage. Another important characteristic of monolithic refractories is their high thermal conductivity. This property facilitates the efficient transfer of heat away from the refractory lining, reducing the risk of thermal stress and thermal fatigue. The refractories can effectively disperse the heat generated during the smelting process, minimizing the temperature differentials within the lining and preventing cracks or fractures. Furthermore, monolithic refractories possess good chemical resistance, which is crucial in aluminum smelting applications. They are formulated to resist the corrosive effects of molten aluminum and other chemicals present in the smelting process. This resistance helps to maintain the integrity of the refractory lining and prolong its service life. Additionally, monolithic refractories are often reinforced with fibers or other structural materials to enhance their mechanical strength and durability. These reinforcements provide added resistance against mechanical stresses, such as thermal expansion and contraction, which occur during the thermal cycling process. In conclusion, monolithic refractories are designed to withstand the thermal cycling conditions encountered in aluminum smelting applications. Their excellent thermal shock resistance, high thermal conductivity, good chemical resistance, and mechanical strength allow them to endure the extreme temperature fluctuations without significant damage. These refractories play a crucial role in maintaining the integrity and efficiency of the smelting process in the aluminum industry.

Send your message to us

Castable Cement Refractory Cement For Fireplace and Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords