Casing Coupling of Size 9-5/8 LC K55 with API Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Structure of Product Description

Casing Coupling can be widely used in cold and hot water supply, heating supply, fire protection, medicinal gas, industrial petroleum pipeline system etc.

It has already replaced welding fittings in most Europe countries, Asia countries, America, Australia and some other countries.

2) Main Features of the Product

The quality of our products are very good, customers are all very satisfied. We have professional service team and export experience for a lot of years, our products have exported to more than 200 countries in the world. Here you can take easy choosing your needed products.

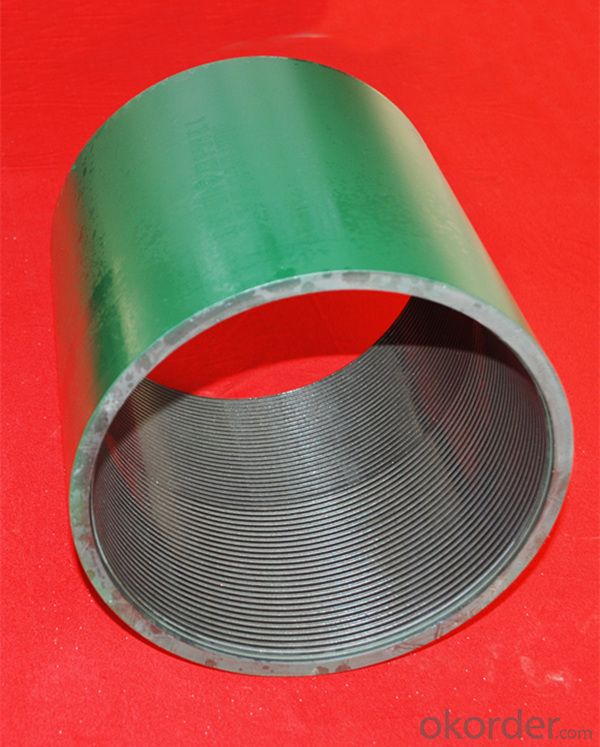

This product in the photos is 9-5/8 LC K55 casing coupling,used to connect oil casing pipe, which is transporting oil and gas from underground to the suiface after the drilling is completed.

3) Images

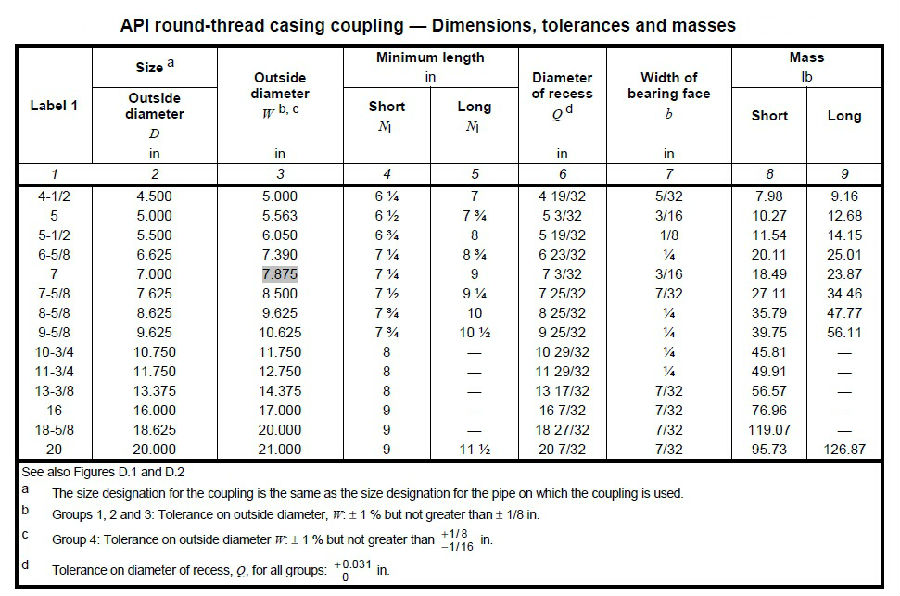

4) Product Specification

5) FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in steel pipe products in China, mainly offering four series steel pipes including welded steel pipe (ERW, SSAW, LSAW and square and rectangle pipe), seamless steel pipe, hot dipped galvanized steel pipe and steel pipe with 3 layer polythene coating. We can provide customers different specification standards e.g. ASTM A53, ASTM A106, BS1387, API 5L, API 5CT, ISO3183 and etc. Our scope of supplying covers from 1/2" to 48" for the outside diameter of welded pipes, and 1/8" to 20" for the seamless pipes.

Other than steel pipes we are also capable of supplying a wide variety of pipeline accessories, steel pipe fittings; valves etc. consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: What 17th century Catholic Priest invented the first working parachute?

- The alarm buttons on the key locker things *i dont know what to call them either* require you to hold the buttoun down for about 3 seconds so you definetley shouldn't worry about hitting it by accident

- Q: As shown in Figure six, the angle of the edge distance 71mm, diagonal 80mm, about 34mm high; and its connection of the pipe joint exposed a small section, measured its outer diameter is 57mm; through these parameters can see the pipe joint screw size is how much? Or see the specifications of the hose.To take something in this, it is not convenient to disassemble temporarily, that can check through standard size, I do not know the check which standard, hose and pipe joint standards are many, I do not call up this kind... Please explain to the master, this call what, check what standard, how to check, through the above parameters can get out what size, etc., thank you very much!! PS: the key is size. Now you're going to do the connection

- Hydraulic joint standardHydraulic pipe fittings - thread standard twoClassification of threadsThe 1. threaded internal and external threads two;2. according to the shape of teeth can be divided into: 1) triangular thread 2) trapezoidal thread 3) rectangular thread 4) sawtooth thread;3. by line, single, head and multi thread;4., according to the direction of rotation, two kinds of left and right threads, the right is not marked, left plus LH, such as M24 * 1.5LH;5. according to different uses are: metric common thread, thread sealed pipe thread, non threaded sealing pipe thread, 60 degrees taper pipe thread, metric taper thread, etc.

- Q: My computer in an office network and I do not have internet access permission. How can connect with my colleague computer to access the internet ?. is wingate will work ?

- IS 1239 : Part 1~Steel Tubes, Tubulars and Other Wrought Steel Fittings - Specification - Part 1 : Steel Tubes IS 1239 : Part 2~Mild steel tubes, tubulars and other wrought steel fittings, Part 2 Mild steel tubulars and other wrought steel pipe fittings First IS code will serve your purpose.standardsbis.in/Gemini/search

- Q: I suck at this stuff. I have an F and grades close really soon.1. Potential energy is the energy of?2. Kinetic energy depends on?3. Gravitational potential energy depends on?4. 5 renewable resources and 5 nonrenewable resources.5. What kind of energy is stored in a stretched rubber band?6.At what point does a roller coaster have the greatest potential energy?Help if you can please. I'll answer any question you want if I can!!Thank you. (:

- You forgot to to give us a picture of the crossword.

- Q: does anyone know what the lights are called at a zebra crossing and why they are called that?

- second generation dakota 1990-1996 look for one with the v-6. i presently have 145k on mine,and know others who work the dog-poo outta theres with well over 300k. lift kits are availible to gain the crucial extra inches for dealing with the nasty roads.and the front axle is stron enough to accept a 33 tire. ( only caveat there is its a 6 lug pattern ) with a kn air filter,and a hi-flow exhaust muffler i get 21 to the gal in the city. also many gen 3 ( 1997-2003) dakotas have much of the same running gear. vehicle is also stout enough for mounting a winch too. trim packages range from bare bones to lavish. for dealing with the harsh weather an protecting the body,id suggest having a rhino linings sprayed onto the quarter panels to lock out moisture.

- Q: PT1/4 large diameter pipe joint? No figure urgently

- Taper Pipe Thread is an inch taper pipe thread standard with a thread shape of 55 degrees

- Q: I have an automatic 2005 Toyota Matrix with power locks and windows. For some reason, when my husband pressed the beeper to unlock all the doors, all the doors unlocked except the driver side door. I thought maybe it was a fluke, but this morning, when I unlocked the car, it did the same thing.Also, I have the car set so that when it is put into gear it automatically locks all the doors. Again, the doors all lock except the driver side. Even when I push the button to lock the doors that is on the door, all the locks lock except the driver side.I didn't know if maybe a weird button was pressed or if something is wrong with the lock. Any ideas? And also, if something is wrong with the lock, any suggestions on getting it fixed? price? or any other relevant info would be great!!! Thanks.

- Sabiki rig. The answer that a cast net will catch you more is only good if you can see them and they are not near structure. I catch many baitfish on sabiki rigs before I go grouper fishing off docks that have lots of oyster shells. Sweeten the pot a little. Attach bloodworm fish bites to the hooks in small pieces and you will carch them left and right

- Q: Also, whats one word for separation of charge

- That power isn't strong enough to merit the 1.56, and may cause aberrations in the lensesthe regular 1.50 is perfect. There is no thickness factor to worry about at that power.

- Q: What are some good lab safety rules? Are the Physics rules any different from that of Biology or Chemistry?

- It's not the schools responsibility. I would contact the local police dept. I did so on a guy who would speed by the elementary school. The cops staked out an area and pulled him over. Also, your city council could work on installing speed bumps on the street as well.

- Q: I think OSHA would require safety goggles around those things..

- Gorilla Glue is just right, but weight it down at the same time it dries. GG expands something like 30% and makes air bubbles when drying, so if it can be no longer weighted, the rubber piece will stick up and may ooze. Use sparingly!

Send your message to us

Casing Coupling of Size 9-5/8 LC K55 with API Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 PCS

- Supply Capability:

- 50000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords