Carton Steel Seamless Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Seamless Pipe ASTM A103:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe, we always to provide you discount, we are trying to give every customer best price and satisfy price.

2、Main Features of the Seamless Pipe ASTM A103:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Stronger heat dissipation ability

• Good visual effect

• More reasonable price

3、Seamless Pipe ASTM A103Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A103:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.We company professional to provide these serious of pipes and what we can give you is not only in good sprice, the most important is we can provide you good quality.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

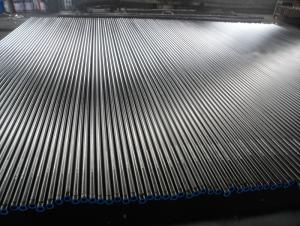

6、Seamless Pipe ASTM A103Images:

- Q: What are the different methods of pipe lining for steel pipes?

- Some of the different methods of pipe lining for steel pipes include slip lining, cured-in-place pipe lining (CIPP), pipe bursting, and sliplining. Slip lining involves inserting a smaller diameter pipe into the existing steel pipe, while CIPP involves inserting a resin-impregnated liner into the pipe and curing it in place. Pipe bursting involves breaking the existing steel pipe and replacing it with a new pipe, while sliplining involves inserting a new pipe into the existing steel pipe without breaking it.

- Q: How are steel pipes used in the manufacturing of bicycles?

- Steel pipes are commonly used in the manufacturing of bicycles as they provide strength, durability, and rigidity to the frame structure. The pipes are typically used to construct the main frame, handlebars, seat post, and fork, ensuring a sturdy and reliable bicycle.

- Q: SC15 what does galvanized steel pipe look like?

- Ordinary galvanized steel pipe, the outer diameter is 1.5 inches

- Q: What's the difference between a cracked carbon steel tube and a liquid carbon steel tube?

- Test: cracking carbon steel pipe in addition to eddy current testing, but also to do ultrasonic testing, and liquid carbon steel tubes are generally only eddy current testing.

- Q: Can steel pipes be used for underground pressure pipelines?

- Yes, steel pipes can be used for underground pressure pipelines. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for underground applications where pressure is present. Additionally, steel pipes can withstand high temperatures and external forces, making them an ideal choice for underground pressure pipelines.

- Q: How are steel pipes used in data centers?

- Steel pipes are used in data centers for the installation of cooling systems, electrical wiring, and network cabling, providing a robust and reliable infrastructure to support the data center's operations.

- Q: How do steel pipes compare to other pipe materials like PVC or copper?

- Steel pipes have several advantages over other pipe materials like PVC or copper. Firstly, steel pipes are incredibly durable and can withstand high levels of pressure and extreme temperatures, making them suitable for a wide range of applications. Secondly, steel pipes have excellent resistance to corrosion, which ensures their longevity and reduces the need for frequent maintenance or replacement. Additionally, steel pipes have a higher strength-to-weight ratio compared to PVC or copper, making them more robust and capable of handling heavy-duty tasks. However, steel pipes can be more expensive and require special equipment for installation. Overall, steel pipes are a reliable and versatile option that offers superior durability and performance compared to other pipe materials.

- Q: What are the different types of steel pipe supports for offshore platforms?

- There are several types of steel pipe supports used for offshore platforms, including clamps, brackets, hangers, and saddles. These supports are designed to secure and stabilize the pipes, ensuring their durability and integrity in the harsh offshore environment.

- Q: How are steel pipes used in construction?

- Steel pipes are commonly used in construction for various purposes such as structural support, plumbing, and transportation of fluids and gases. They are used in building frameworks, bridges, and underground infrastructure, providing strength, durability, and flexibility. Steel pipes are often employed in plumbing systems for water supply and drainage. Additionally, they serve as conduits for conveying gas, oil, and other substances. Their versatility and strength make steel pipes an essential component in modern construction projects.

- Q: What are the different types of steel pipe connections for fire sprinkler systems?

- There are several types of steel pipe connections used in fire sprinkler systems including threaded connections, grooved connections, flanged connections, and welded connections.

Send your message to us

Carton Steel Seamless Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords