All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

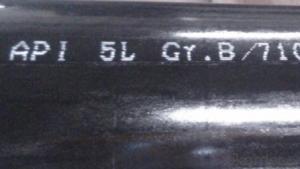

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can a welded steel pipe be used for oil and gas transportation?

Yes, a welded steel pipe can be used for oil and gas transportation. Welded steel pipes provide high strength and durability, making them suitable for transporting oil and gas over long distances. They can withstand high pressure, corrosion, and extreme temperatures, ensuring the safe and efficient transportation of these resources.

What is the difference between gas metal arc welding and gas tungsten arc welding for welded steel pipe?

Gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW) are two different welding processes used for welding steel pipes.

The main difference between these two methods lies in the type of electrode used. GMAW, also known as MIG welding, employs a consumable wire electrode that is continuously fed through the welding gun. This wire electrode acts as the filler material, melting and joining the base metals together.

On the other hand, GTAW, commonly referred to as TIG welding, utilizes a non-consumable tungsten electrode. In this process, a separate filler material is added manually to the weld joint as needed. The tungsten electrode generates an arc that heats the base metals, and the filler material is then added to form the weld.

In the context of welded steel pipes, GMAW is often preferred due to its high welding speed, productivity, and ease of use. It is commonly used in industrial settings for large-scale pipe welding projects. GTAW, on the other hand, is typically used for specialized applications that require higher precision and control, such as in joining pipes with smaller diameters or in situations where a higher quality weld is needed.

Overall, the choice between GMAW and GTAW for welding steel pipes depends on factors such as the specific requirements of the project, the weld quality needed, and the expertise of the welder.

Can welded steel pipes be used for sewage disposal systems?

Yes, welded steel pipes can be used for sewage disposal systems. Welded steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for handling sewage and waste materials. Additionally, their smooth interior surface helps prevent clogs and allows for efficient flow of sewage.

How do welded steel pipes handle changes in temperature?

Welded steel pipes handle changes in temperature quite well due to their inherent strength and durability. The welding process ensures a strong and secure joint, allowing the pipes to expand and contract without significant deformation or leakage. Additionally, steel has a low coefficient of thermal expansion, meaning it expands and contracts at a relatively slower rate compared to other materials. This property enables welded steel pipes to handle temperature fluctuations, maintaining their structural integrity and functionality over a wide range of temperatures.

What are the different factors that can affect the elongation of welded steel pipe?

There are several factors that can affect the elongation of welded steel pipe. These include the type and quality of the steel used, the welding process and technique employed, the temperature and heat treatment during welding, the presence of impurities or defects in the steel, and the applied mechanical stresses or loads on the pipe.

Wholesale Welded Steel Pipe from supplier in Botswana

With our extensive experience and expertise in the field, we understand the specific requirements and challenges of the Botswana market. We have built strong relationships with local suppliers and manufacturers, allowing us to offer competitive prices and high-quality products.

Our sales team is dedicated to providing exceptional customer service and ensuring that you find the right Welded Steel Pipe products for your projects. We can assist you in selecting the appropriate specifications, sizes, and quantities to meet your specific needs.

In addition to sales, we also offer comprehensive technical support services. Our team of experts can provide guidance on installation, maintenance, and troubleshooting, ensuring that your Welded Steel Pipe products perform optimally.

We pride ourselves on our commitment to customer satisfaction and strive to exceed your expectations. Whether you are looking for a single Welded Steel Pipe or require a large quantity for a major project, we are here to support you every step of the way.

Contact us today to discuss your Welded Steel Pipe requirements in Botswana and experience the difference of working with a renowned supplier backed by a Fortune Global 500 company.

Our sales team is dedicated to providing exceptional customer service and ensuring that you find the right Welded Steel Pipe products for your projects. We can assist you in selecting the appropriate specifications, sizes, and quantities to meet your specific needs.

In addition to sales, we also offer comprehensive technical support services. Our team of experts can provide guidance on installation, maintenance, and troubleshooting, ensuring that your Welded Steel Pipe products perform optimally.

We pride ourselves on our commitment to customer satisfaction and strive to exceed your expectations. Whether you are looking for a single Welded Steel Pipe or require a large quantity for a major project, we are here to support you every step of the way.

Contact us today to discuss your Welded Steel Pipe requirements in Botswana and experience the difference of working with a renowned supplier backed by a Fortune Global 500 company.