Capri Blue PPGI Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

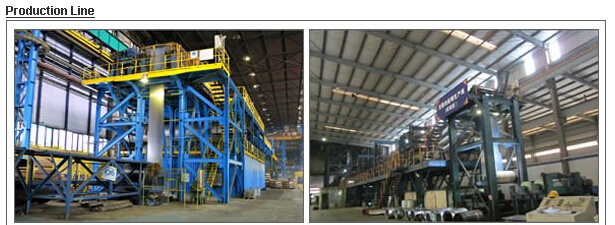

PPGI Coil1.Common polyester paint

2.50-150g/m2 dipped layer

3.2 Coating 2 Baking process

4.Long life span

PPGI Coil

Brief Introduction

1. PPGI Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for PPGI Coil is HDG steel. The finish coats of PPGI Coils can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

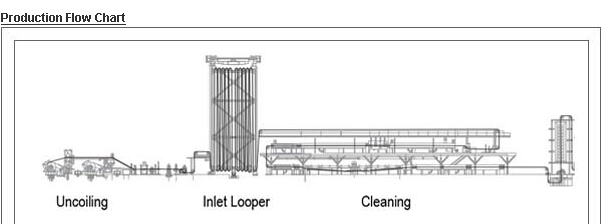

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the PPGI Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The PPGI Coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

- Q: What are the different types of steel beams used in building structures?

- There are several different types of steel beams commonly used in building structures, including I-beams, H-beams, and C-beams. These beams vary in shape and size, with I-beams being the most commonly used due to their versatility and strength. H-beams are similar to I-beams but have wider flanges, providing additional support for larger structures. C-beams, also known as channel beams, have a C-shaped cross-section and are often used as support elements in smaller structures or as framing members.

- Q: What is the role of steel in the energy sector?

- Steel plays a crucial role in the energy sector as it is used in the construction of various infrastructure and equipment necessary for energy generation, transmission, and storage. From power plants, wind turbines, and solar panels to pipelines, storage tanks, and transmission towers, steel provides strength, durability, and reliability to support the efficient and safe production, distribution, and utilization of different forms of energy.

- Q: How is steel used in the manufacturing of consumer goods?

- Steel is used in the manufacturing of consumer goods due to its durability, strength, and versatility. It is commonly used to make appliances, furniture, tools, and vehicles, providing a sturdy structure and ensuring longevity. Additionally, steel is often used in packaging materials and containers to protect and preserve products during transportation and storage.

- Q: How is steel used in the construction of hospitals and healthcare facilities?

- Steel is an essential material in the construction of hospitals and healthcare facilities due to its strength, durability, and versatility. It is commonly used for structural purposes, such as beams, columns, and frames, providing a solid and sturdy framework for the buildings. Steel is also used in the construction of walls, roofs, and floors, ensuring stability and safety. Additionally, steel is often used for medical equipment and fixtures, as it can be easily shaped and fabricated to meet specific requirements. Overall, steel plays a crucial role in ensuring the structural integrity and functionality of healthcare facilities.

- Q: How is steel used in the construction of power plants?

- Steel is used extensively in the construction of power plants due to its strength, durability, and high melting point. It is used for various purposes such as structural support, building frames, boiler components, piping systems, and turbine parts. Steel's properties make it ideal for withstanding high temperatures, pressure, and heavy loads, ensuring the safe and efficient operation of power plants.

- Q: How are steel products used in the construction of high-rise buildings?

- Steel products are extensively used in the construction of high-rise buildings due to their superior strength, durability, and flexibility. Steel is commonly employed for structural frameworks, beams, columns, and reinforcement in high-rise construction. Its high strength-to-weight ratio allows for taller and lighter buildings, while its flexibility enables architects to design complex and innovative structures. Additionally, steel's resistance to fire, earthquakes, and adverse weather conditions makes it a reliable choice for ensuring the safety and stability of high-rise buildings.

- Q: What are the applications of stainless steel in the food industry?

- Stainless steel is widely used in the food industry due to its numerous beneficial properties. It is commonly used for equipment and surfaces that come into contact with food, such as food processing machinery, countertops, sinks, and storage containers. Stainless steel is preferred in the food industry because it is corrosion-resistant, easy to clean and maintain, and highly hygienic. It does not react with food or alter its taste, ensuring the integrity and safety of the products. Additionally, stainless steel is durable, heat-resistant, and can withstand extreme temperatures, making it suitable for a wide range of food processing applications.

- Q: How do steel products contribute to the water and wastewater treatment sector?

- Steel products play a crucial role in the water and wastewater treatment sector due to their durability, strength, and corrosion resistance. They are used extensively in the construction of various infrastructure and equipment, such as pipes, tanks, pumps, and valves, which are essential for transporting, storing, and treating water and wastewater. These steel products ensure the reliability and longevity of the systems, minimizing leaks, failures, and maintenance requirements. Additionally, steel's recyclability and sustainability make it an environmentally friendly choice for the water and wastewater treatment industry.

- Q: What are the common types of steel products used in the chemical industry?

- Some common types of steel products used in the chemical industry include stainless steel pipes, tanks, and vessels, as well as steel valves and fittings. These steel products are chosen for their corrosion resistance properties, as they need to withstand harsh chemicals and environments.

- Q: How is steel tubing used in the manufacturing of heat exchangers?

- Steel tubing is commonly used in the manufacturing of heat exchangers due to its high strength, durability, and heat transfer properties. The tubing is typically formed into a coil or straight sections, allowing for efficient heat transfer between fluids. The steel tubing acts as a conduit for the hot or cold fluid, allowing it to transfer heat to or from another fluid. This enables the heat exchanger to effectively regulate temperature in various industrial processes, such as HVAC systems, power plants, and refrigeration units.

Send your message to us

Capri Blue PPGI Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords