Calcium Silicate Board Better than Gypsum

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcium Silicate Board Better than Gypsum

Asbestos-free Boards Calcium Silicate also known as the porous calcium silicate board, is a fiber-reinforced calcium silicate board, with silicon oxide, calcium oxide, and the reinforcing fibers as the main raw materials, made through mixing, heating, gelling, molding, autoclaving and drying processes. Calcium silicate board is a new type of rigid insulation material.

The calcium silicate board products, also called asbestos free mipor calcium silicate products, are mainly used in industries like power, oil, chemical, shipping, metallurgy, light to provide thermal insulation on industrial pipelines and thermal equipment to decrease heat loss, lower cooling effect on medium and delay its condensation during production, meanwhile save energy, improve work efficiency, lower the temperature at work area, improve working condition, avoid scald among workers.

The calcium silicate board can be specifically used as thermal insulation layer of power plant boiler and turbine body, chemical plant cracking furnace and distillation column, steel plant heating furnace, drying oven, paper mill digesting kettle, also the thermal cover on the pipelines in these plants.

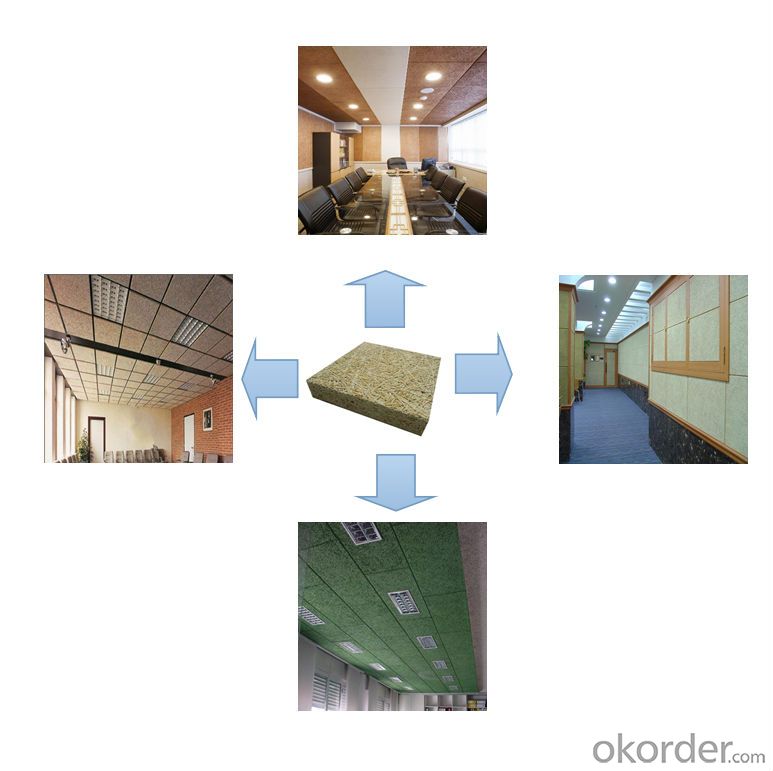

Product Applications:

Calcium Silicate Board are ideal for use in the below applications

Supermarket, marketplace

Underground, air port, bus station

Hall, corridor and toilet

Hotel, restaurant, kitchen

School, office, meeting room ,hospital etc

Product Advantages:

Good durability and can withstand high-temperature limit of the continuous thermal load

Low thermal conductivity,in the whole scope of use is unmatched within the adiabatic Performance

Light weight,high stength,its strength is rigid insulation products in the highest

Durability,long-term use of ceramic fiber felt no similar powder

Construction practical,with ordinary tools can be arbitrarily cutting products

Used safety,hygiene,asbestos-free,sulfur,chlorine such poisonous substances

Main Product Features:

Great soft bulk with elastic.

High strength

The strongest refractory materials among the inorganic thermal materials with similar density

Heat resistance:

Non-deformation within the working temperature range

Thermal insulation:

Lower thermal conductivity compared with other massive hard refractory materials

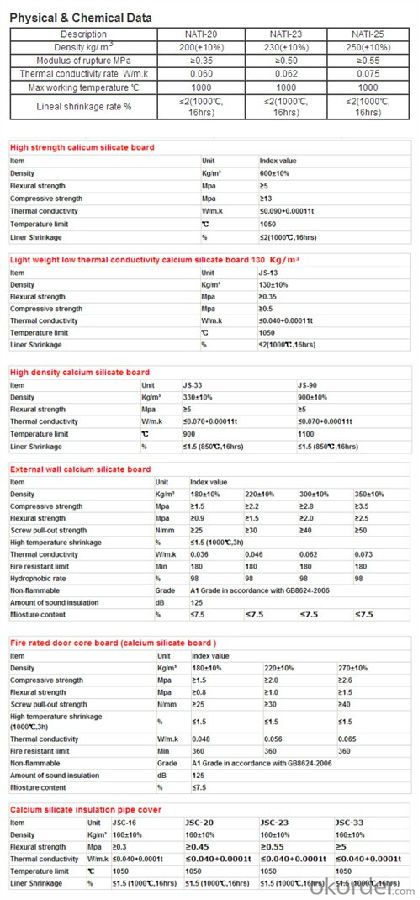

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

Produce Processing

- Q: What kind of insulation material can withstand 350-600 degrees of high temperature?

- GB 50264-97 code for design of thermal insulation engineering for industrial equipment and pipelines98T901 cold storage Atlas of piping and equipment

- Q: What is the difference between calcium silicate board and cement fiber board?

- Fiber cement pressure plate is cement, fiber and other raw materials, after pulping, molding, thousands of tons of press. Calcium silicate board is made of silica and calcium plus fibrous material after pulping and formed by chemical reaction in high temperature environment. Therefore, the difference between the two is very large, mainly in the following aspects:1, from raw materials, calcium silicate board and fiber cement pressure plate difference is mainly calcium silicate board cement content is little, with sand and fly ash instead of cement.2, fiber cement pressure plate is a physical product, calcium silicate board is a chemical product.3, fiber cement pressure plate has press, calcium silicate board has no press; calcium silicate board has autoclaved Fu, fiber cement pressure plate no..4. The density of the fiber cement pressure plate is higher than that of the calcium silicate board, the density of the fiber cement pressure plate is above 1.5g/cm3, and the density of the calcium silicate board is about 1.2g/cm3.5, fiber cement pressure plate thickness can do 2.5-100mm, calcium silicate board can not do less than 4mm of ultra-thin plates and more than 30mm super thick plate, general calcium silicate board manufacturers can only do 6-12mm thickness.6, the normal production of fiber cement pressure plate color is cement color, calcium silicate board color is white.

- Q: What heat preservation material is used for thermal insulation of steam pipe in power plant? How thick is the bag? Please advise!

- Steam pipe in power plant thermal insulation rock wool board thickness, according to the temperature in the pipeline to choose, the higher the temperature insulation thickness is generally 80 to 150 mm.

- Q: Why is calcium silicate board unsuitable for use in home improvement?

- Because the silica plate contains quartz composition, and the content is still higher. Quartz is a carcinogenic substance, the long-term impact of this substance, the human carcinogenic probability will be greatly enhanced

- Q: What are the main use of lime?

- Lime milk and mortar, slaked lime or lime paste, with lots of paint. Lime mortar or slaked lime powder can be used to prepare lime mortar or cement lime mixture mortar for masonry or plastering engineering.

- Q: What's the difference between white cement and ordinary cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q: Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- The market is generally understood, but in fact, Eterpan belongs to Guangzhou eternit limited production of the 100 year history of eternit brand board, because the cement product is Belgium hetet group invention.

- Q: How to make building glue?

- The invention relates to an architectural adhesive, which is characterized in that the composition of the building glue comprises 28-50wt% sodium silicate water solution, 34-53wt% quartz sand and 8-35wt% magnesium silicate.Adhesive for a building, it is the following: the weight ratio of 4 to 6, PVA cellulose 6 - 12, 1 - 2, copolymer admixture from 0.01 to 0.05, according to the proportion of polyvinyl alcohol with hot water first fully dissolved, then adding cellulose, copolymer, admixture and stir evenly. The glue can be combined with Portland cement or construction gypsum to cement all kinds of light plates. This product is non-toxic and tasteless, harmless to the human body, is a wide range of uses, superior technical performance of environmentally friendly building adhesive.

- Q: What is dew point of thermal insulation material?

- Insulation materials, insulation for industrial equipment and piping, thermal insulation measures and material aerogels were first applied to the space suit thermal insulation linings developed by nasa. With low thermal conductivity, small density, high flexibility, fire, waterproof and other characteristics. Its temperature coefficient of thermal conductivity 0.018W/ (K = m) and absolute waterproof, insulation performance is 3~8 times of traditional materials.

- Q: What are the exterior walls of the building besides the benzene board and the extruded board?

- Composite silicate insulation material has the characteristics of strong plasticity, low thermal conductivity, high temperature resistance, small drying shrinkage and so on. The main types are magnesium silicate, silicon magnesium aluminum and rare earth composite thermal insulation materials. But in recent years as a leader in thermal insulation material of Sepiolite Composite silicate insulation material, because of its good insulation performance and the application effect, has attracted great attention in the construction industry, has shown strong market competitiveness and broad market prospect.

Send your message to us

Calcium Silicate Board Better than Gypsum

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords