Calcined Anthracite Coal CA Description

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

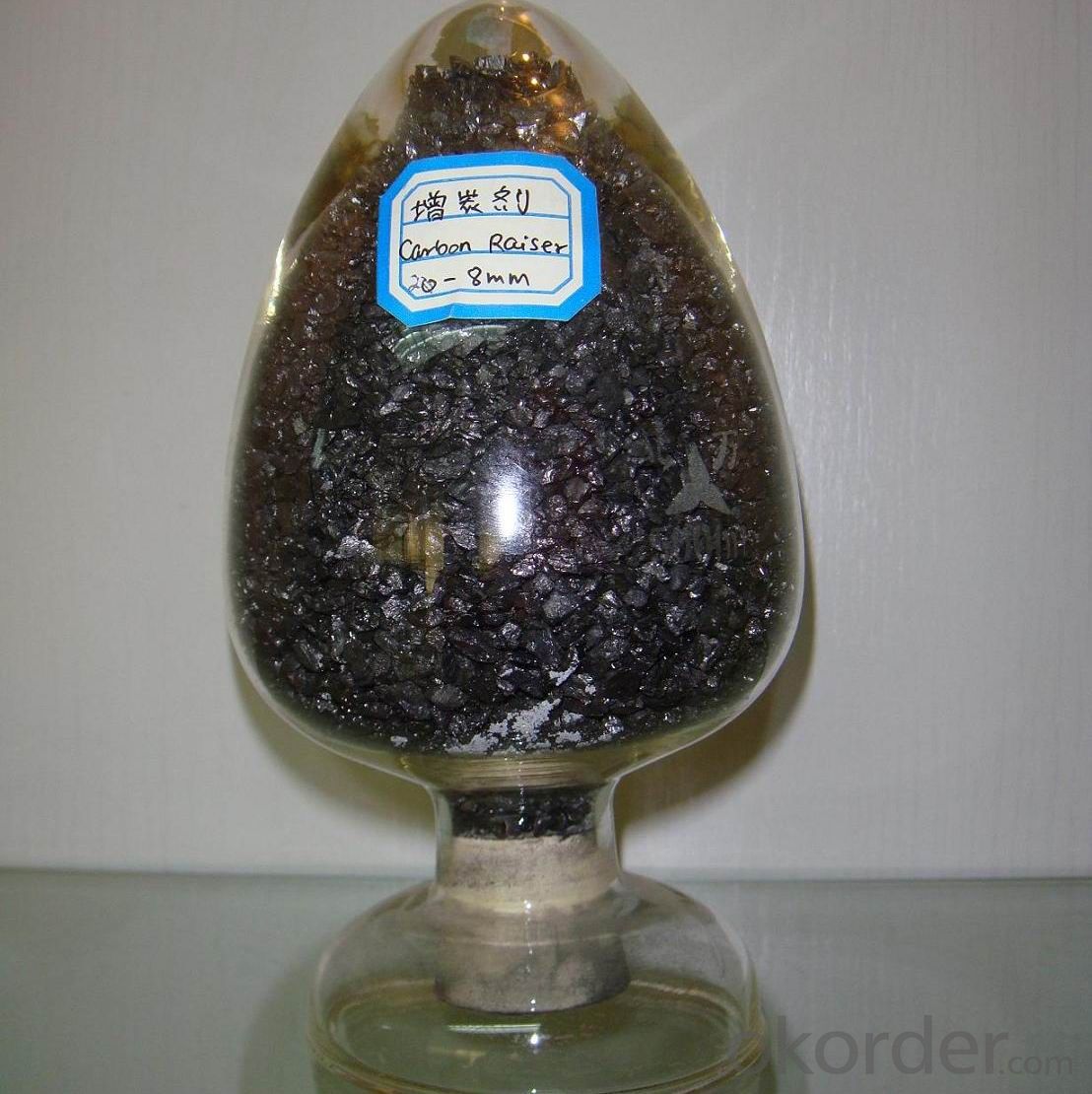

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Calcined Anthracite Coal CA Description

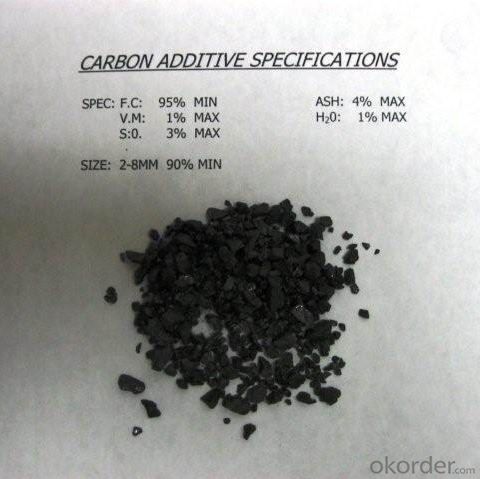

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Calcined Anthracite Coal CA Description

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

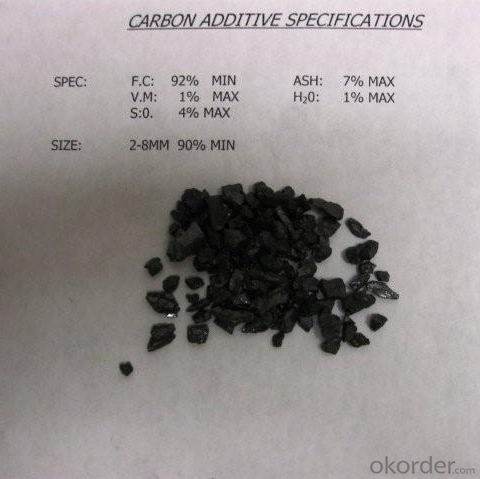

Calcined Anthracite CA Description

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Calcined Anthracite Coal CA Description

FAQ:

Calcined Anthracite Coal CA Description

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Calcined Anthracite Coal CA Description

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: There is a graphite mine, looking for three experts engaged in mineral processing industry asked. They say earthy graphite, and the answer to the taste is quite different. Some say that the fixed carbon content of 15, and some say graphite grade 90%. The same sample. Some people say that very valuable, and some say that the grade is too low, worthless. I'm all confused. What do you mean by graphite grade and fixed carbon?

- No, fixed carbon is the index of industrial analysis in coal, which is used to calculate calorific value. Graphite grade refers to the content of graphite in graphite ore.

- Q: What are the uses of carbon nanotubes?

- Due to their unique properties, carbon nanotubes find wide application across various industries. In the realm of electronics and semiconductors, they are particularly valuable. With exceptional electrical conductivity, carbon nanotubes are ideal for creating smaller and more efficient electronic devices. They can be incorporated as conductive additives in polymers, resulting in materials with enhanced electrical and thermal properties. Another crucial domain where carbon nanotubes excel is materials science. Their exceptional mechanical strength and lightweight nature make them ideal for reinforcing and strengthening materials. By incorporating carbon nanotubes into composites, their mechanical properties can be improved, making them more durable. Furthermore, their usage in constructing super-strong fibers finds relevance in industries such as aerospace and construction. Carbon nanotubes have also found valuable applications in the medical field. They can be utilized in drug delivery systems, wherein drugs are encapsulated within the nanotube structure and directly delivered to specific cells or tissues. This method enables more effective and targeted drug delivery, minimizing the side effects associated with traditional drug administration methods. Additionally, carbon nanotubes are being explored as a potential material for biosensors, facilitating the early detection of diseases and pathogens. In the realm of energy storage, carbon nanotubes are being extensively researched as an alternative to conventional lithium-ion batteries. Their potential to store more energy and charge faster could revolutionize the field of energy storage and power generation. Additionally, carbon nanotubes can be employed as catalysts in fuel cells, enhancing their efficiency and cost-effectiveness. In summary, the applications of carbon nanotubes are vast and continue to expand as new discoveries are made. From electronics to materials science, medicine to energy storage, these nanotubes have the potential to revolutionize various industries and enhance the performance of existing technologies.

- Q: Why can carbon fiber in addition to static electricity ah?

- Is graphite conductive? Think about it!

- Q: How is carbon used in the production of paints and pigments?

- Carbon is used in the production of paints and pigments primarily as a black pigment. Carbon black, which is derived from the incomplete combustion of hydrocarbons, is mixed with binders to create black paints and pigments. It provides excellent opacity, color retention, and UV resistance, making it a popular choice in various applications, including automotive coatings, printing inks, and architectural paints.

- Q: What are some common compounds of carbon?

- Carbon forms a wide range of compounds due to its unique ability to bond with other carbon atoms and a variety of other elements. Some common compounds of carbon include carbon dioxide (CO2), methane (CH4), ethanol (C2H5OH), ethene (C2H4), acetic acid (CH3COOH), and glucose (C6H12O6). These compounds are essential in various fields such as biology, chemistry, and industry. For example, carbon dioxide is a greenhouse gas that plays a crucial role in the Earth's climate system, methane is a potent greenhouse gas released during natural gas production and contributes to climate change, ethanol is a common alcohol used as a fuel and solvent, ethene is used to produce plastics, acetic acid is a key component in vinegar, and glucose is a primary source of energy for living organisms. These compounds highlight the versatility and importance of carbon in the world around us.

- Q: What is the structure of carbon-based polymers?

- The structure of carbon-based polymers is characterized by a chain-like arrangement of carbon atoms, forming the backbone of the polymer. These carbon atoms are typically bonded to other atoms or groups of atoms, such as hydrogen, oxygen, nitrogen, or halogens, through covalent bonds. The properties of the polymer are determined by the arrangement and connectivity of these atoms. In addition to the carbon backbone, functional groups are often present in carbon-based polymers. These functional groups are specific combinations of atoms that can give the polymer unique chemical properties. They can be attached to different points along the carbon backbone, adding chemical diversity and altering the behavior of the polymer. The monomers, which are the repeating units in carbon-based polymers, can vary in size and complexity. For instance, simple hydrocarbons like ethylene can undergo polymerization to form polyethylene, which consists of a long chain of carbon atoms with attached hydrogen atoms. On the other hand, more complex monomers like acrylonitrile or styrene can be utilized to produce polymers like polyacrylonitrile or polystyrene, respectively. These polymers incorporate additional atoms or functional groups, resulting in distinct properties and applications. In conclusion, carbon-based polymers possess a diverse structure that can be customized to fulfill specific requirements. This versatility allows them to be utilized in a wide array of industries, including plastics, textiles, and electronics.

- Q: How does carbon affect the formation of ground-level ozone?

- Carbon is a key contributor to the formation of ground-level ozone, also known as smog. When carbon-containing pollutants, such as vehicle exhaust and industrial emissions, are released into the atmosphere, they react with sunlight and other pollutants to form ground-level ozone. This reaction occurs more rapidly in the presence of high levels of carbon, leading to increased ozone concentrations.

- Q: What are the consequences of increased carbon emissions on tourism industry?

- The consequences of increased carbon emissions on the tourism industry include the deterioration of natural attractions, such as coral reefs and glaciers, which are major tourist draws. Additionally, extreme weather events and rising sea levels can damage infrastructure and disrupt travel plans. The industry may also face increased regulations and taxes aimed at reducing carbon emissions, leading to higher operational costs for businesses. Overall, the consequences of increased carbon emissions on the tourism industry are detrimental to both the environment and the economy.

- Q: What is carbon capture and storage?

- Carbon capture and storage (CCS) is a process that involves capturing carbon dioxide emissions from industrial sources, such as power plants, and storing them underground or using them for various purposes. It aims to mitigate the release of greenhouse gases into the atmosphere, helping to combat climate change by reducing carbon dioxide levels.

- Q: How is carbon used in the production of paints?

- Carbon is used in the production of paints in several ways. One of the main uses of carbon in paint production is as a pigment. Carbon black, which is a form of elemental carbon, is commonly used as a black pigment in various types of paints. It provides a deep and intense black color, as well as excellent light absorption properties, making it ideal for creating dark shades in paints. Carbon also plays a role in the formulation of certain types of paints, such as carbon-based coatings. These coatings are used in applications where resistance to heat, chemicals, and corrosion is required. Carbon-based coatings are often used in industries like automotive, aerospace, and marine, where durability and protection are crucial. These coatings can be applied to various surfaces, providing a high level of protection and extending the lifespan of the painted object. In addition, carbon is used as a filler material in some types of paints. Carbon fillers are added to improve the mechanical properties of the paint, such as its strength, hardness, and resistance to wear and tear. Carbon fillers also enhance the overall performance of the paint, making it more durable and long-lasting. Overall, carbon is an essential ingredient in the production of paints, serving as a pigment, a component of coatings, and a filler material. Its versatile properties make it a valuable addition to various paint formulations, enhancing the aesthetic appeal, durability, and performance of the final product.

Send your message to us

Calcined Anthracite Coal CA Description

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords