Building Steel Rods SAE 1006 1008

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 120 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Steel Rods

Description of Building Steel Rods

1, Diameter: 5.5mm-10mm Building Steel Rods

10m- 40mm Building Steel Rods

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Building Steel Rods

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

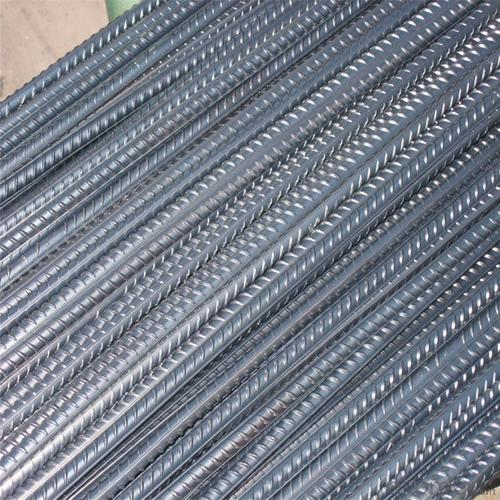

Products Show of Building Steel Rods

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the common challenges in machining titanium alloys?

- The common challenges in machining titanium alloys include their high chemical reactivity, low thermal conductivity, high cutting forces, and poor chip control. Additionally, titanium alloys tend to work harden, making them prone to tool wear and requiring frequent tool changes. Moreover, their low modulus of elasticity can lead to vibration and chatter during machining operations, affecting surface quality and dimensional accuracy.

- Q: What are the different mining grades of special steel?

- The different mining grades of special steel can vary depending on the specific composition and properties required for different applications. Some common mining grades include stainless steel, tool steel, high-speed steel, and alloy steel. Each grade has unique characteristics that make it suitable for specific mining operations, such as resistance to corrosion, high strength, hardness, and wear resistance.

- Q: What are the different forms of special steel?

- There are several different forms of special steel, including stainless steel, tool steel, high-speed steel, alloy steel, and spring steel. Each form has unique properties and is designed for specific applications in various industries.

- Q: What are the different heat treatment processes used in special steel production?

- Some of the different heat treatment processes used in special steel production include annealing, tempering, quenching, and case hardening.

- Q: How is special steel used in the railway supply chain?

- Special steel is used in the railway supply chain for various applications such as manufacturing railway tracks, wheels, axles, and components. It offers superior strength, durability, and resistance to wear and tear, ensuring safe and efficient transportation. Special steel's unique properties make it an essential material in constructing reliable and high-performance railway infrastructure.

- Q: Can special steel be used in corrosive environments?

- Yes, special steel can be used in corrosive environments. Special steels like stainless steel and corrosion-resistant alloys are specifically designed to withstand corrosion and maintain their structural integrity in harsh and corrosive environments such as marine, chemical, or industrial settings. These steels contain additional alloying elements like chromium, nickel, or molybdenum, which provide enhanced corrosion resistance properties, making them suitable for use in corrosive environments.

- Q: What are the main characteristics of creep-resistant steel forgings?

- Creep-resistant steel forgings possess a range of essential qualities that render them suitable for applications involving high temperatures and prolonged stress and heat exposure. To begin with, these forgings are renowned for their exceptional resistance to creep deformation. Creep refers to the gradual deformation that occurs under constant load and elevated temperatures over an extended period. These forgings are specifically designed to withstand such deformation, retaining their shape and structural integrity. Consequently, they are ideal for use in environments with high temperatures, such as turbine blades, boiler components, and other similar settings. Another crucial characteristic of creep-resistant steel forgings is their impressive strength. These forgings are manufactured using alloying elements like chromium, molybdenum, and vanadium, which enhance their tensile strength. As a result, they exhibit excellent resistance to deformation and fracture under high-stress conditions. This strength is essential for ensuring that the forgings can endure the demands of various applications and perform reliably over time. Furthermore, creep-resistant steel forgings demonstrate good resistance to oxidation and corrosion. The presence of alloying elements creates a protective layer on the surface, safeguarding against oxidation and corrosion at elevated temperatures. This resistance is vital in preventing the degradation of the material and maintaining its mechanical properties, even in harsh environments. Moreover, creep-resistant steel forgings offer outstanding thermal stability. They can endure extreme temperature fluctuations without significant dimensional changes or loss of mechanical strength. This stability is particularly critical in applications that involve rapid heating and cooling cycles, ensuring that the forgings can sustain their performance under challenging conditions. Additionally, creep-resistant steel forgings possess excellent fatigue resistance. Fatigue refers to the weakening of a material resulting from cyclic loading, which is particularly relevant in high-temperature applications due to the combination of stress and heat. These forgings are designed to withstand cyclic loading and retain their mechanical properties, thus reducing the risk of fatigue failure and enhancing the overall reliability of the component. In conclusion, the primary characteristics of creep-resistant steel forgings encompass resistance to creep deformation, high strength, good oxidation and corrosion resistance, thermal stability, and excellent fatigue resistance. These qualities establish creep-resistant steel forgings as a reliable and durable choice for applications requiring resistance to high temperatures, stress, and prolonged exposure to challenging environments.

- Q: What are the properties of electrical steel?

- Electrical steel, also known as silicon steel, possesses specific properties that make it ideal for use in electrical equipment. It exhibits low core loss, high permeability, and high magnetic saturation, enabling efficient energy conversion and minimizing power losses. Additionally, electrical steel has a high resistivity, reducing eddy currents and further improving its performance in transformers, motors, and generators.

- Q: How is special steel used in the mining supply chain?

- Special steel is used in various components and equipment used in the mining supply chain. It is commonly used in the construction of heavy machinery, such as mining trucks, excavators, and drilling rigs, as well as in the fabrication of conveyor belts and crushing equipment. Additionally, special steel is utilized in the production of wear-resistant parts, such as grinding balls and liners, which are crucial for efficient ore processing. Its exceptional strength, durability, and resistance to extreme conditions make it an essential material in the mining industry, ensuring safe and efficient operations throughout the supply chain.

- Q: What are the main advantages of using special steel in the construction of bridges?

- The main advantages of using special steel in the construction of bridges are its exceptional strength and durability. Special steel alloys offer high tensile strength, allowing for lighter bridge designs and reducing the overall weight of the structure. This not only makes construction and transportation easier but also minimizes the environmental impact. Additionally, special steel exhibits excellent corrosion resistance, ensuring the longevity of the bridge even in harsh weather conditions. Its superior toughness and resistance to fatigue make it ideal for withstanding heavy loads and frequent use, ensuring the safety and reliability of the bridge for many years.

Send your message to us

Building Steel Rods SAE 1006 1008

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 120 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords