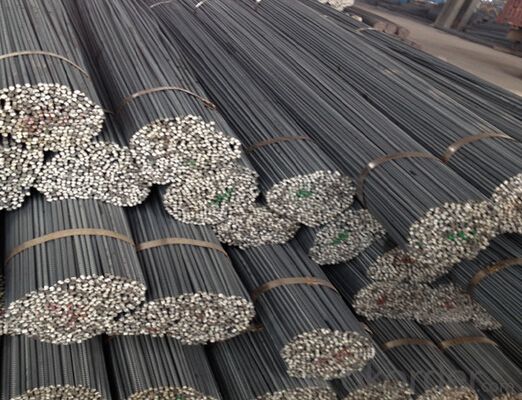

BS4449 B460B Steel Rebar/Deformed bar Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

Square,U Channel,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

BS4449 B460B Steel Rebar/Deformed bar Made in China

Details of the BS4449 B460B Steel Rebar/Deformed bar Made in China

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the BS4449 B460B Steel Rebar/Deformed bar Made in China

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the BS4449 B460B Steel Rebar/Deformed bar Made in China

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: What is the weight of a standard steel rebar?

- The weight of a standard steel rebar can vary depending on its size and length.

- Q: What is the process of connecting steel rebars to structural members?

- To establish a secure and dependable connection, several steps are involved in connecting steel rebars to structural members. To begin with, the structural member's design specifications necessitate the precise positioning of the long, ridged or deformed steel bars called rebars. This is typically accomplished by using spacers or chairs to maintain the appropriate spacing between the rebars and the surrounding formwork. Following that, the rebars are connected to the structural member through various means. A common method is lap splicing, where the rebars overlap for a designated distance and are then tied together using wire or mechanical connectors. The length of the overlap is determined by engineering calculations to ensure adequate strength and load transfer. Another approach involves the use of pre-fabricated mechanical couplers, which provide a dependable connection between the rebars. These couplers are designed to securely grip the rebars and effectively transfer the load. They offer advantages such as quicker installation, reduced labor costs, and enhanced structural integrity. In addition to splicing, the rebars may also need to be anchored or hooked into the structural member. Anchoring involves extending the rebar's length beyond the connection point and bending it back into the concrete to create a hook shape. This provides additional resistance against pull-out forces. Throughout the process, it is crucial to ensure that the rebars are clean, free from rust, and properly aligned. Any contaminants or misalignments can weaken the connection and compromise the structural integrity. Therefore, comprehensive inspection and quality control measures are essential to ensure a successful connection. Overall, the process of connecting steel rebars to structural members requires meticulous planning, precise positioning, proper splicing or coupling, and thorough inspection. By following these steps, a robust and long-lasting connection can be achieved, guaranteeing the safety and stability of the structure.

- Q: Can steel rebars be used in the construction of road bridges or flyovers?

- Yes, steel rebars can be used in the construction of road bridges or flyovers. Steel rebars provide the necessary strength and durability required to support heavy loads and withstand the stresses and strains experienced by these structures. They are commonly used as reinforcement in concrete structures, including road bridges and flyovers, to enhance their structural integrity and ensure long-term stability.

- Q: What are the different types of steel rebars used in beams and columns?

- There are several types of steel rebars commonly used in beams and columns, including carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. Each type has its own specific characteristics and advantages, making them suitable for various applications in construction projects.

- Q: Can steel rebars be used in the construction of hospitals and healthcare facilities?

- Yes, steel rebars can be used in the construction of hospitals and healthcare facilities. Steel rebars provide structural integrity and strength to the buildings, ensuring their safety and durability. Additionally, steel rebars are resistant to fire, moisture, and corrosion, making them suitable for healthcare facilities that require high standards of cleanliness and hygiene.

- Q: How do steel rebars prevent concrete from cracking?

- Concrete cracking is prevented by steel rebars, as they reinforce it and increase its strength. When concrete is poured, it is initially in a liquid state and lacks tensile strength, making it prone to cracking under tension. However, steel rebars are embedded within the concrete structure, creating a strong bond as it hardens. The rebars function as a framework within the concrete, evenly distributing tensile forces throughout the structure. When external forces, such as load or temperature changes, act on the concrete, the rebars resist the tensile stresses that would otherwise cause cracks. This is because steel possesses significantly higher tensile strength compared to concrete. Furthermore, steel rebars also assist in managing cracks that may arise due to shrinkage during the concrete curing process. As the concrete dries and hardens, a chemical reaction causes it to shrink. This shrinkage has the potential to cause cracks, but the presence of rebars restrains excessive expansion or contraction, reducing the likelihood of cracking. Not only do steel rebars prevent cracks, but they also enhance the overall structural integrity of the concrete. They aid in evenly distributing loads, resulting in a concrete structure that is more resistant to bending, shearing, and other forces. This reinforcement ensures that the concrete can withstand anticipated loads and maintain stability over time. In summary, steel rebars play a vital role in preventing concrete from cracking by providing tensile strength and reinforcement. Through the distribution of tensile forces, control of shrinkage, and enhancement of structural integrity, they ensure that the concrete remains strong, durable, and crack-resistant. As a result, the lifespan of the concrete is prolonged, and its stability is ensured.

- Q: What are the different types of couplers used for connecting steel rebars?

- There are various types of couplers used for connecting steel rebars, including mechanical couplers, lap splices, and welded couplers. Mechanical couplers are commonly used due to their ease of installation and ability to provide a strong connection. Lap splices involve overlapping the rebars and tying them together with wire or other fasteners. Welded couplers, on the other hand, require the rebars to be welded together to form a connection. Each type of coupler has its own advantages and disadvantages, and the choice depends on factors such as the project requirements, rebar size, and construction method.

- Q: Can steel rebars be used in cold storage construction?

- Yes, steel rebars can be used in cold storage construction. Steel rebars are commonly used in the construction of cold storage facilities due to their strength, durability, and ability to withstand low temperatures. They provide structural reinforcement to the concrete walls, floors, and ceiling, ensuring the integrity and stability of the cold storage structure. Additionally, steel rebars are resistant to corrosion, which is important in maintaining the longevity of the cold storage facility in a low-temperature environment.

- Q: Can steel rebars be used in swimming pool construction?

- Yes, steel rebars can be used in swimming pool construction. They are often used as reinforcement in the concrete structure of the pool to provide strength and durability. The rebars help to prevent cracking and ensure the pool can withstand the pressure of the water.

- Q: What is the difference between steel rebars and steel mesh?

- Concrete structures in construction projects commonly use steel rebars and steel mesh to reinforce them. However, there are notable distinctions regarding their design and application. Steel rebars, also called reinforcing bars, are lengthy cylindrical steel rods. They are typically employed to provide tensile strength to concrete structures. These rebars are usually arranged in a grid-like pattern within the concrete, preventing cracks and improving the overall structural integrity. Rebars come in various sizes and are used in applications where significant tensile force is anticipated, such as columns, beams, and slabs. On the other hand, steel mesh, also known as wire mesh or welded wire fabric, consists of interconnected steel wires that are welded together to create a grid-like pattern. This mesh is usually produced in large rolls and can be easily cut or bent into the desired shape. Steel mesh primarily offers both tensile and shear strength to concrete structures. It is commonly used in applications where a lower amount of tensile force is expected, like walls, foundations, and pavements. Regarding installation, steel rebars are usually placed and secured within the concrete formwork prior to pouring the concrete. They are positioned at specific locations according to the structural design requirements. Conversely, steel mesh is laid on top of the formwork or within the concrete pour itself, providing reinforcement throughout the entire concrete structure. Both steel rebars and steel mesh possess their own advantages and disadvantages. Rebars provide greater tensile strength and are excellent for applications involving heavy loads or high amounts of force. However, they can be more time-consuming and labor-intensive to install due to the individual placement and tying process. On the other hand, steel mesh offers easier and faster installation due to its continuous form, making it more commonly used in smaller-scale projects or applications with lighter loads. In conclusion, while both steel rebars and steel mesh serve the purpose of reinforcing concrete structures, they differ in terms of design, installation method, and application. The choice between rebars and mesh depends on specific structural requirements, project scale, and load expectations. It is advisable to consult with a structural engineer or construction professional to determine the most suitable reinforcement solution for a particular project.

Send your message to us

BS4449 B460B Steel Rebar/Deformed bar Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords