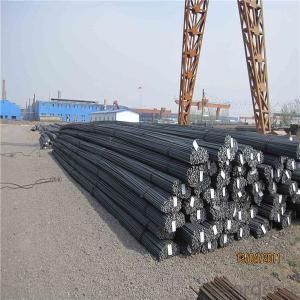

HRB335 deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering HRB335 deformed steel bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

HRB335 deformed steel bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's deformed steel bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2.00 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

50 | 1964 | 15.42 | 185.04 | 5.40 |

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of Deformed Steel Rebar for Construction HRB400, HRB500, Gr40, Gr60:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Deformed Steel Rebar for Construction HRB400, HRB500, Gr40, Gr60:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Label:to be specified by customer, generally, each bundle has 1-2 labels

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: What are the safety precautions to be followed while working with steel rebars?

- When working with steel rebars, it is important to follow several safety precautions to ensure a safe working environment. Some of these precautions include wearing personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against potential hazards. Additionally, workers should be trained on proper handling techniques to prevent injuries. It is also crucial to ensure that the work area is well-ventilated to prevent exposure to harmful fumes. Regular inspections of the equipment and tools used should be conducted to identify and address any potential hazards. Finally, communicating and adhering to safety protocols, such as proper lifting techniques and maintaining a clutter-free work area, are essential to minimize accidents and injuries while working with steel rebars.

- Q: How do steel rebars affect the overall weight of a concrete structure?

- Steel rebars play a vital role in reinforcing concrete structures and have a significant impact on the structure's weight. Typically made of carbon steel, which is renowned for its strength and durability, rebars provide tensile strength when combined with concrete. The addition of rebars increases the weight of a concrete structure, although the effect on the overall weight is relatively minimal compared to the advantages they offer. While the weight of rebars is significantly lower than that of concrete, their inclusion does contribute to the total weight. The primary purpose of rebars is to reinforce the concrete and ensure its ability to withstand the loads and stresses imposed on the structure. By distributing the tensile forces throughout the concrete, rebars prevent cracking and structural failure. As a result, they enable the construction of larger and more robust structures, including bridges, buildings, and highways. Although the weight of rebars increases the overall weight of a concrete structure, it is a necessary compromise for improved strength and durability. The additional weight from the rebars is typically insignificant compared to the weight of the concrete itself. Moreover, when considering the overall load-bearing capacity and structural integrity of the entire construction, the increased weight is often negligible. In conclusion, steel rebars have a minor impact on the overall weight of a concrete structure, but the benefits they provide are significant. By reinforcing the concrete, rebars ensure its structural integrity, durability, and the ability to construct larger, safer, and more resilient structures.

- Q: Can steel rebars be used in reinforced masonry?

- Yes, steel rebars can be used in reinforced masonry. Reinforced masonry refers to the use of steel reinforcement within masonry walls, columns, or other structural elements to increase their strength and resistance to various forces. Steel rebars are commonly used as reinforcement in reinforced masonry due to their high tensile strength and ability to withstand bending and stretching forces. The rebars are typically embedded within the masonry units or mortar, creating a composite structure that can resist compressive, tensile, and shear forces more effectively. The use of steel rebars in reinforced masonry enhances the structural integrity, durability, and overall performance of the masonry construction, making it a widely accepted and practiced technique in the industry.

- Q: How are steel rebars protected against alkali attacks?

- Steel rebars are protected against alkali attacks through the use of various techniques and materials. One common method is to apply a protective coating on the surface of the rebars. This coating acts as a barrier, preventing direct contact between the alkaline environment and the steel. Some commonly used coatings include epoxy, zinc, and polyethylene. These coatings are designed to be durable and provide long-term protection against alkali attacks. Another method of protection is through the use of corrosion inhibitors. These inhibitors are added to the concrete mixture during construction. They work by reducing the corrosive effects of alkali on the steel rebars. Corrosion inhibitors form a protective film on the surface of the steel, preventing the alkali from reaching the rebar and causing damage. In addition to coatings and corrosion inhibitors, proper concrete mix design can also play a significant role in protecting rebars against alkali attacks. By optimizing the composition of the concrete mix, engineers can reduce the alkalinity of the environment surrounding the rebars. This helps to minimize the risk of alkali attacks and subsequent corrosion. Regular maintenance and inspection of structures is crucial in ensuring the continued protection of steel rebars against alkali attacks. Monitoring the condition of the rebars and taking prompt action in case of any signs of corrosion or damage is essential for their long-term durability. Overall, a combination of protective coatings, corrosion inhibitors, proper concrete mix design, and regular maintenance are key factors in safeguarding steel rebars against alkali attacks. By implementing these measures, the lifespan and structural integrity of concrete structures can be significantly extended.

- Q: Can steel rebars be used in the construction of educational institutions?

- Yes, steel rebars can be used in the construction of educational institutions. Steel rebars are commonly used in reinforced concrete structures to provide strength and reinforcement. They help to strengthen the concrete and improve its resistance to structural loads, making them suitable for use in various construction projects, including educational institutions.

- Q: Are steel rebars cost-effective compared to other reinforcement materials?

- Yes, steel rebars are generally considered cost-effective compared to other reinforcement materials. Steel rebars are widely available, durable, and have high tensile strength, making them suitable for various construction projects. Additionally, their longevity and low maintenance requirements contribute to their cost-effectiveness in the long run.

- Q: What are the different grades of epoxy-coated steel rebars?

- The different grades of epoxy-coated steel rebars typically vary based on their mechanical properties, such as tensile strength and yield strength. Some common grades include ASTM A775/A775M-07 Grade 60, ASTM A775/A775M-07 Grade 40, and ASTM A934/A934M Grade 60. These grades are designated based on the specific requirements and standards set by various organizations and regulatory bodies.

- Q: How are steel rebars used in bridge construction?

- Steel rebars are used in bridge construction to provide reinforcement and strength to the concrete structures. They are embedded within the concrete to help resist tension forces, prevent cracking, and enhance the overall structural integrity of the bridge. Additionally, rebars help distribute loads evenly, increase durability, and ensure the longevity of the bridge.

- Q: Are steel rebars suitable for use in tunnels and underground mines?

- Tunnels and underground mines can benefit greatly from the use of steel rebars. These reinforcement bars, also called steel rebars, are commonly utilized in construction due to their strength and durability. In environments where structural integrity is crucial, such as tunnels and underground mines, steel rebars offer the necessary reinforcement to withstand the heavy loads and pressures associated with these settings. Steel rebars possess exceptional tensile strength, enabling them to resist bending and cracking even under high stress. This attribute is particularly important in tunnels and underground mines, where the surrounding rock and soil exert significant pressure on the structure. By reinforcing the concrete or other structural materials with steel rebars, the overall strength and stability of the tunnel or mine are enhanced, mitigating the risk of collapse or damage. Moreover, steel rebars exhibit resistance to corrosion, rendering them suitable for use in underground environments where moisture and chemical exposure are prevalent. Corrosion can weaken reinforcement materials, compromising the safety of the tunnel or mine. Conversely, steel rebars provide long-lasting reinforcement, ensuring the infrastructure's longevity and reliability. Additionally, steel rebars offer convenience in fabrication and installation, making them a practical choice for tunnel and underground mine construction. They can be easily cut and bent into specific shapes and sizes, facilitating customized reinforcement solutions tailored to the unique requirements of each project. This versatility and ease of installation make steel rebars an advantageous option for tunnels and underground mines, which often encounter complex geometries and challenging conditions. In conclusion, steel rebars are an ideal choice for tunnels and underground mines due to their strength, durability, corrosion resistance, and ease of installation. By utilizing steel rebars as reinforcement, these structures can be built to withstand demanding conditions, ensuring the safety of workers and the long-term viability of the infrastructure.

- Q: How do steel rebars affect the overall durability of a structure?

- Steel rebars play a crucial role in enhancing the overall durability of a structure. By providing reinforcement to concrete, they contribute to the structural integrity and longevity of the building. The presence of rebars helps to distribute and withstand tensile forces, increasing the load-bearing capacity of the structure. One of the primary benefits of steel rebars is their ability to resist cracking and prevent the propagation of cracks in concrete. As concrete is weak in tension, the introduction of rebars helps to absorb and distribute tensile stresses, reducing the likelihood of cracks forming. This is particularly important in areas prone to seismic activity or other dynamic forces. Moreover, rebars also offer excellent resistance to corrosion, which is a common threat to the durability of structures, especially those in coastal or humid environments. The steel used in rebars is typically treated with corrosion-resistant coatings or made from stainless steel, ensuring long-term protection against rust and deterioration. The inclusion of steel rebars in concrete structures also enhances their resistance to fire. Steel has a high melting point, and when embedded in concrete, it acts as a heat sink, slowing down the spread of fire and providing additional time for evacuation and firefighting efforts. In summary, steel rebars significantly contribute to the overall durability of a structure by improving its resistance to cracking, corrosion, and fire. Their ability to reinforce concrete and withstand tensile forces ensures the structural stability and longevity of the building, making it more resilient to various environmental and man-made hazards.

Send your message to us

HRB335 deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords