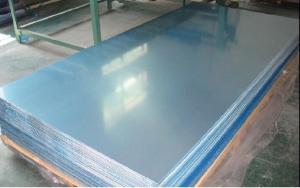

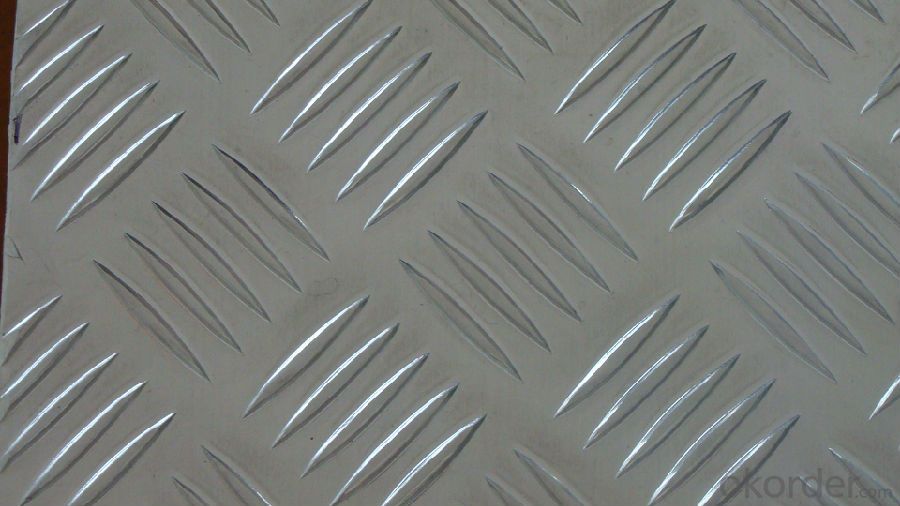

Composite Aluminum Sheets in San Diego - Brushed Aluminum Sheet 2mm Thick and Other Standard Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Discription:

Aluminum Sheets

Alloy No.: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 5083, 5754, 8011, 8006, 8079, etc..

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm - 2100mm

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: What specific treatments or coatings are required for exterior applications to ensure durability and protection?

- <p>Yes, for exterior applications, special coatings or finishes are often necessary to protect against weathering, UV radiation, and other environmental factors. These may include weather-resistant paints, UV-resistant coatings, and corrosion-resistant finishes. For example, in construction, exterior walls might be treated with a water-repellent coating to prevent water damage, while metal structures may require anti-corrosion coatings to withstand harsh weather conditions. The choice of coating depends on the material, climate, and specific requirements of the application.</p>

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces.

- Q: Can 101 aluminum sheets be anodized?

- Indeed, the anodization of 101 aluminum sheets is feasible. Anodization, which entails the formation of a safeguarding oxide layer on the aluminum's surface, enhances its resilience against corrosion and overall durability. This technique can be employed on different aluminum grades, including 101, to achieve desired finishes and offer added protection. The anodization process can be executed through diverse methods such as chromic acid anodizing, sulfuric acid anodizing, or hardcoat anodizing, depending on specific needs and desired outcomes. Consequently, it is assured that 101 aluminum sheets can undergo anodization procedures.

- Q: Does anyone know why Mercury -(Thimerosal) is used in Flu Vaccinations and where Mercuryisnot used Aluminium in other vaccines ? While these are known to be toxic metals, can these cause headaches, severe hot burning heads and or Sinusitus ?

- Thimerosal is not the same as mercury. It's a mercury-based preservative which to prevent the growth of germs, bacteria and fungi, that can contaminate them. It's used in seasonal flu vaccine because the vaccine is produced in large quantities and often in multi-dose vials. Thimerosal helps safeguard against possible contamination of the vial once it is opened. The aluminum in vaccines is aluminum hydroxide, aluminum phosphate, alum (potassium aluminum sulfate), or mixed aluminum salts. They're an adjuvant added to enhance the immune response in the vaccinated individual. Whether or not something is toxic has to do with how much a person receives not the substance itself. People can die from drinking too much water, but we don't go around calling water toxic. The amount of mercury or aluminum in vaccines is so small that it's not toxic. You ingest more mercury by eating fish and a baby ingest more aluminum in breast milk than they get in a vaccine. So if mercury and aluminum caused head aches, severe hot burning heads or sinusitis in a person, that person would have a lot more to worry about than vaccines since they would be exposed to those things in so many other ways.

- Q: How do aluminum sheets perform in terms of weldability?

- The weldability of aluminum sheets is generally good because of their low melting point and excellent thermal conductivity. Various techniques, such as TIG welding, MIG welding, or spot welding, can be used to weld aluminum sheets. However, there are a few factors that can affect the weldability of aluminum sheets. First, it is necessary to ensure that the surface of the aluminum sheet is clean and free from contaminants like oil, grease, or oxide layers. These contaminants can have a negative impact on the weld quality. Therefore, it is crucial to clean and prepare the surfaces to be welded properly. Second, aluminum sheets have a high thermal conductivity, which means that heat dissipates quickly. This can make it difficult to control the temperature during the welding process. To ensure a successful weld, it is important to have a skilled and experienced welder who can adjust the welding parameters accordingly. Lastly, aluminum sheets have a high coefficient of thermal expansion, which can result in distortion or warping during welding. To minimize these issues, techniques such as tack welding or clamping may be used to hold the sheets in position. In conclusion, aluminum sheets generally have good weldability due to their low melting point and excellent thermal conductivity. However, achieving high-quality welds and avoiding potential issues like contamination, distortion, or warping requires proper surface preparation, skilled welding techniques, and careful temperature control.

- Q: This question asks for guidance on selecting a trustworthy supplier for purchasing aluminum sheets.

- <p>To choose a reliable supplier of aluminum sheets, consider the following: Check their reputation by reading reviews and testimonials. Ensure they have a valid certification and adhere to industry standards. Evaluate their product quality by requesting samples or visiting their production site. Assess their delivery times and reliability. Confirm they offer competitive pricing without compromising on quality. Look for suppliers with good customer service and after-sales support. Finally, consider their financial stability and ability to fulfill large orders.</p>

- Q: How does the surface roughness of aluminum sheet affect its performance?

- The surface roughness of an aluminum sheet can significantly affect its overall performance. The roughness of the surface refers to the irregularities, bumps, and texture present on the sheet's surface. These irregularities can be measured using various methods, such as Ra (arithmetical average roughness) or Rz (mean roughness depth). One significant impact of surface roughness on aluminum sheet performance is in its ability to bond or adhere to other materials. A smoother surface allows for better adhesion, whether it is through welding, gluing, or painting. When the surface is rough, it creates less contact area and reduces the strength of the bond. This is particularly crucial in applications where the aluminum sheet is used as a structural component or in manufacturing processes that require strong adhesion. Surface roughness also affects the sheet's ability to reflect light. A smoother surface reflects light more uniformly, resulting in a higher level of reflectivity. In contrast, a rough surface scatters light in multiple directions, reducing its overall reflectivity. This property is relevant in applications such as architectural cladding, where the desired aesthetic appearance may rely on the sheet's ability to reflect light consistently. Moreover, the surface roughness of aluminum sheets can impact their corrosion resistance. A smoother surface is less prone to corrosion as it provides fewer sites for corrosion initiation. On the other hand, a rougher surface may have micro crevices or grooves that can trap moisture, salts, or other corrosive substances, accelerating the corrosion process. In applications where corrosion resistance is critical, such as marine environments or outdoor structures, maintaining a smooth surface is essential. Lastly, surface roughness affects the sheet's mechanical properties. A rough surface can act as stress concentrators, leading to increased susceptibility to fatigue, cracks, or other mechanical failures. Smoother surfaces distribute stress more evenly, enhancing the sheet's overall strength and resistance to deformation. In conclusion, the surface roughness of an aluminum sheet plays a vital role in its performance. It impacts adhesion, reflectivity, corrosion resistance, and mechanical properties. Therefore, considering and controlling the surface roughness is essential in various applications to ensure optimal performance and longevity of aluminum sheets.

- Q: Excuse me: what kind of aluminum sheet is the cheapest? Which materials are more expensive?

- Among them, 3003 for aluminum manganese alloy, the lowest price in the 3 series, and then 3004.3104, for aluminum, magnesium, manganese alloy than 3003 price to be slightly higherThird bit, 5 series, i.e. aluminum magnesium alloy, such as 5005.50525083. 5005 of these prices are slightly lowerThen, the ---2 system and --4 system and --7 system of the 6 series are derived

- Q: Are 101 aluminum sheets resistant to UV radiation?

- Generally speaking, 101 aluminum sheets exhibit resistance to UV radiation. This is due to the formation of a natural thin oxide layer on the surface of aluminum, which serves as a protective shield against UV rays. Consequently, the aluminum is safeguarded from deterioration or degradation when exposed to sunlight. Nevertheless, it is worth noting that prolonged exposure to intense UV radiation can still result in gradual discoloration or fading. Therefore, in situations where the aluminum sheets will be continuously exposed to direct sunlight for long durations, it is recommended to consider applying a protective coating or utilizing a specialized UV-resistant paint. These measures will further enhance the aluminum sheets' ability to withstand UV radiation.

- Q: This question asks for the various types of adhesives that can be used for bonding aluminum profiles when constructing exterior cladding.

- <p>For bonding aluminum profiles in exterior cladding, several types of adhesives are commonly used. These include: 1. Structural adhesives, which provide strong and durable bonds suitable for load-bearing applications. 2. Silicone sealants, known for their flexibility and resistance to weathering, making them ideal for sealing gaps and joints. 3. Acrylic adhesives, which offer good adhesion and flexibility, and are often used for bonding aluminum to other materials. 4. Epoxy adhesives, known for their high strength and resistance to chemicals, making them suitable for demanding environments. 5. Polyurethane adhesives, which provide strong bonds and excellent resistance to moisture and temperature changes. The choice of adhesive depends on factors such as the specific application, environmental conditions, and required performance characteristics.</p>

Send your message to us

Composite Aluminum Sheets in San Diego - Brushed Aluminum Sheet 2mm Thick and Other Standard Sizes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords