High Performance Ladle Sliding Gate for Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

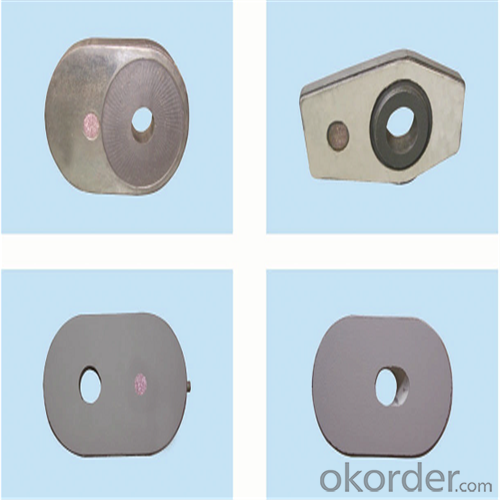

Quick Details for High Performance Refractory Ladle Slide Gate

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

Using the raw materials of tabular alumina, zirconia-corundum, carbon and other high-grade additives, after sintering to obtain characteristics of oxidation resistance, scour strength, erosion resistance, thermal shock resistance, shape stable and long service life, made our products the preferred materials for the large and medium-sized steel ladle, refining ladle, series of alloy steel ladle, and tundish. Our high performance sintering sliding gates include alumina carbon , Al2O3-ZrO2-C, etc, can meet the needs of different steel grade.

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

About us

Sample is on your request.

Welcome to visit our factory~

- Q:How do monolithic refractories resist chemical attacks from molten metals and slag?

- Monolithic refractories are specifically designed to resist chemical attacks from molten metals and slag. They possess several key characteristics that enable them to withstand these aggressive environments. Firstly, monolithic refractories are composed of high-quality materials that have excellent chemical resistance. These materials, such as alumina, magnesia, and chrome, have a high melting point and are stable even when exposed to extreme temperatures and corrosive substances. This chemical stability ensures that the refractory can maintain its integrity and structural strength when in contact with molten metals and slag. Secondly, monolithic refractories have a dense and compact structure. This microstructure helps to prevent the penetration of molten metals and slag into the refractory material. The dense structure acts as a barrier, limiting the contact between the corrosive substances and the refractory. This reduces the chances of chemical reactions and erosion, thereby enhancing the resistance of the refractory to chemical attacks. Furthermore, monolithic refractories often contain additives and binders that enhance their chemical resistance. These additives create a protective layer on the refractory surface, acting as a shield against chemical attacks. They can also react with certain corrosive substances, forming stable compounds that further resist the penetration and corrosion of the refractory material. Additionally, monolithic refractories are designed to have low porosity. This low porosity minimizes the absorption of molten metals and slag, preventing them from infiltrating the refractory and causing damage. By reducing the permeability of the material, the refractory can maintain its structural integrity and resist chemical attacks over prolonged periods. In conclusion, monolithic refractories resist chemical attacks from molten metals and slag through their high-quality materials, dense structure, additives, and low porosity. These combined properties allow the refractories to withstand aggressive environments and maintain their performance and longevity in industrial applications.

- Q:What are the typical compositions of monolithic refractories?

- Monolithic refractories are typically composed of a combination of aggregates, binders, and additives. Aggregates are materials such as alumina, magnesia, or silicon carbide that provide the main refractory properties. The choice of aggregate depends on the desired characteristics of the refractory, such as resistance to high temperatures, thermal shock, or chemical attack. Binders are used to bind the aggregates together and give the refractory its shape and strength. Common binders include clay, calcium aluminate cement, or colloidal silica. The binder also contributes to the overall performance of the refractory, influencing properties such as thermal conductivity and chemical resistance. Additives are often incorporated into the composition to improve specific properties or enhance the processing of the monolithic refractory. These additives can include plasticizers, which improve workability and allow for easier installation, or antioxidants, which can increase the refractory's resistance to oxidation. Overall, the specific composition of a monolithic refractory can vary depending on the intended application and the desired performance characteristics. Different combinations of aggregates, binders, and additives can be tailored to suit specific temperature ranges, chemical environments, or mechanical stresses.

- Q:How can the lifespan of monolithic refractories be extended in the iron and steel industry?

- The lifespan of monolithic refractories can be extended in the iron and steel industry through proper installation, regular maintenance, and implementing effective refractory management practices. This includes using high-quality refractory materials, ensuring precise installation techniques, monitoring and controlling operating conditions, conducting regular inspections, and promptly addressing any signs of wear or damage. Additionally, optimizing heating and cooling cycles, implementing appropriate refractory lining designs, and incorporating advanced technologies can further enhance the longevity of monolithic refractories in this industry.

- Q:How are monolithic refractories installed in iron and steel production processes?

- The installation of monolithic refractories in iron and steel production processes necessitates various methods depending on the specific application and requirements. The installation process typically encompasses the subsequent steps: 1. Surface Preparation: Prior to installing monolithic refractories, it is imperative to adequately prepare the surface where they will be applied. This involves cleansing and eliminating any loose materials, dust, or contaminants from the substrate. 2. Mixing: Monolithic refractories comprise diverse materials, including aggregates, binders, and additives. These constituents are blended in specific proportions to attain the desired properties and consistency. The mixing process can be executed manually or using mechanical mixers. 3. Application: Various techniques exist for applying monolithic refractories, such as gunning, casting, ramming, and troweling. The chosen method is contingent upon factors such as the structure's shape, accessibility, and required thickness. - Gunning: This technique entails utilizing a gunning machine to spray the refractory material onto the surface. It is frequently employed for repairing or patching existing linings or for swift installation in hard-to-reach areas. - Casting: In casting, the refractory material is poured into molds or forms and allowed to solidify and harden. This method is suitable for fabricating intricate shapes and large-sized components. - Ramming: Ramming involves manually or mechanically compacting the refractory material into a mold or form using a ramming tool. This approach is commonly employed for lining induction furnaces, ladles, and other equipment. - Troweling: Troweling is a manual method wherein the refractory material is applied and smoothed using a trowel. It is frequently utilized for minor repairs or touch-ups. 4. Curing: Subsequent to the application of the refractory material, curing is necessary to attain its optimal strength and performance. Curing involves allowing the material to dry and harden at a controlled temperature and humidity for a specified duration. This step is crucial to ensure the monolithic refractory lining's long-term durability and resistance. In conclusion, the installation of monolithic refractories in iron and steel production processes necessitates meticulous preparation, proper mixing, and the appropriate application technique. It is imperative to adhere to manufacturer guidelines and industry best practices to ensure a successful installation that fulfills the specific requirements of the production process.

- Q:How do monolithic refractories improve the durability of furnace linings?

- Monolithic refractories play a crucial role in enhancing the durability of furnace linings due to their unique characteristics and properties. These materials are composed of a single, homogeneous structure, unlike traditional brick refractories that consist of individual bricks or tiles. One of the key ways in which monolithic refractories improve the durability of furnace linings is through their ability to eliminate joints and seams. In traditional brick refractories, the joints between the bricks can be weak points where cracks and failures can occur due to thermal expansion and contraction. Monolithic refractories, on the other hand, are poured or gunned into place, ensuring a seamless lining. This seamless structure minimizes the potential for cracks, making the lining more durable and less susceptible to thermal stress. Monolithic refractories also have excellent thermal shock resistance, which is crucial for furnace linings that are subjected to rapid and extreme temperature changes. The monolithic structure allows for better heat transfer and distribution, preventing localized hotspots that can lead to thermal shock and lining failure. This enhanced thermal shock resistance ensures that the furnace lining can withstand the repeated heating and cooling cycles without significant damage, hence improving its overall durability. Additionally, monolithic refractories offer superior erosion and corrosion resistance. Furnace linings are often exposed to harsh chemicals, molten metals, and abrasive materials, which can cause erosion and corrosion over time. Monolithic refractories are designed to resist these corrosive agents, protecting the lining from chemical attacks and physical wear. This resistance ensures a longer lifespan for the furnace lining and reduces the need for frequent repairs or replacements. Furthermore, monolithic refractories provide better insulation properties compared to traditional brick refractories. They have lower thermal conductivity, meaning that heat transfer through the lining is minimized. This insulation property helps to maintain a more stable and uniform temperature within the furnace, reducing thermal stress on the lining and contributing to its longevity. In summary, monolithic refractories improve the durability of furnace linings by eliminating joints and seams, enhancing thermal shock resistance, providing erosion and corrosion resistance, and offering superior insulation properties. These materials are specifically designed to withstand the extreme conditions inside furnaces, ensuring a longer lifespan for the lining and reducing maintenance costs in the long run.

- Q:What are the typical properties of monolithic refractories used in iron and steel industry?

- Monolithic refractories used in the iron and steel industry typically possess high thermal conductivity, excellent resistance to thermal shock, and high mechanical strength. They are also known for their ability to withstand high temperatures and harsh chemical environments. Additionally, these refractories exhibit good erosion and abrasion resistance, low porosity, and high density, making them ideal for lining furnaces, ladles, and other equipment in the iron and steel production process.

- Q:What are the common failure mechanisms of monolithic refractories?

- Some common failure mechanisms of monolithic refractories include thermal shock, spalling, erosion, chemical attack, and mechanical stress. These factors can weaken the refractory material, causing it to crack, break, or deteriorate over time.

- Q:How do monolithic refractories improve the quality and consistency of iron and steel products?

- Monolithic refractories play a crucial role in improving the quality and consistency of iron and steel products. These refractories are unshaped and can be easily molded and installed, providing several advantages over traditional brick refractories. Firstly, monolithic refractories offer better thermal insulation properties, ensuring effective heat management during the production process. By maintaining consistent and controlled temperatures, these refractories prevent thermal shocks and minimize thermal gradients, leading to reduced cracking and distortion in the final products. This results in improved dimensional stability and overall better quality. Furthermore, monolithic refractories have excellent resistance to thermal spalling and erosion. They can withstand high temperatures, chemical attacks, and mechanical stress, protecting the lining of the furnaces and vessels used in iron and steel production. This resistance enhances the durability and reliability of refractory linings, preventing premature failure and extending the lifespan of the equipment. Another advantage of monolithic refractories is their ability to provide a seamless lining. Unlike brick refractories, which have joints and gaps that can lead to heat loss and uneven distribution, monolithic refractories create a continuous lining with no weak points. This ensures uniform heat distribution and minimizes the risk of hotspots or cold spots, resulting in consistent and reliable iron and steel products. Monolithic refractories also offer flexibility in design and installation. They can be customized to fit various shapes and sizes, allowing for better furnace design optimization. This flexibility enables efficient use of space, improved heat transfer, and reduced energy consumption, all of which contribute to the overall quality and consistency of the final iron and steel products. In summary, monolithic refractories improve the quality and consistency of iron and steel products by providing superior thermal insulation, resistance to thermal spalling and erosion, seamless linings, and flexibility in design and installation. These refractories enhance the efficiency and reliability of the production process, resulting in higher-quality final products that meet the industry's stringent standards.

- Q:How are monolithic refractories different from traditional refractory bricks?

- Monolithic refractories, unlike traditional refractory bricks, are composed of a single, homogeneous structure. This structural distinction leads to several differences between the two. Firstly, monolithic refractories provide greater flexibility and versatility in terms of shape and installation. They can be easily molded and shaped to fit specific applications and complex geometries, making them ideal for lining furnaces, kilns, and other high-temperature equipment. Secondly, monolithic refractories have superior thermal shock resistance compared to traditional refractory bricks. Their uniform structure allows for better heat distribution, minimizing the risk of thermal stress and cracking. This makes them suitable for applications with rapid temperature fluctuations or severe thermal cycling. Additionally, monolithic refractories often exhibit better overall performance in terms of strength, mechanical properties, and resistance to chemical attack. The absence of joints and seams eliminates potential weak points, resulting in a more durable and reliable lining. Moreover, the homogeneous structure provides better resistance to corrosive agents, ensuring prolonged service life in harsh environments. Lastly, monolithic refractories offer advantages in terms of installation and maintenance. Their monolithic nature simplifies the installation process, reducing labor and time requirements. Additionally, repairs and maintenance can be carried out more easily and cost-effectively compared to traditional refractory bricks, which may require the replacement of entire sections or bricks. In summary, monolithic refractories differ from traditional refractory bricks in structure, flexibility, thermal shock resistance, performance, and installation characteristics. These differences make monolithic refractories a preferred choice in many high-temperature applications, offering improved efficiency, durability, and ease of use.

- Q:What are the main challenges in designing the lining system with monolithic refractories?

- The main challenges in designing the lining system with monolithic refractories include ensuring proper installation and curing, achieving adequate strength and durability, managing thermal expansion and contraction, controlling shrinkage and cracking, and maintaining chemical resistance against corrosive environments. Additionally, the selection of suitable raw materials, proper mixing techniques, and effective installation methods are crucial to overcome these challenges and ensure a successful lining system design.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Performance Ladle Sliding Gate for Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords