Hot Rolled MS Mild Heavy Steel Rails for Mines

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled MS Mild Heavy Steel Rails for Mines at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Product Advantages:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

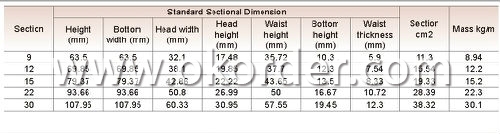

Product Specifications:

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:What are the different loadings that steel channels can withstand?

- Steel channels can withstand a wide range of loadings, making them a versatile and reliable structural component. The specific loadings that steel channels can withstand depend on various factors, including the type and grade of steel, the size and shape of the channel, and the design of the overall structure. Steel channels are commonly used in construction and engineering applications to provide support and stability. They can withstand both static and dynamic loadings, which include dead loads, live loads, and environmental loads. Dead loads refer to the weight of the structure itself, including the weight of the steel channels and any other components or materials. Steel channels are designed to bear this constant load without deformation or failure. Live loads are temporary loads that can vary in magnitude and location. These loads include the weight of people, furniture, equipment, and other transient forces. Steel channels are designed to support these loads and distribute them effectively to other structural members. Environmental loads include wind loads, snow loads, and seismic loads. Steel channels are designed to resist these external forces and maintain the structural integrity of the building or structure. Wind loads can exert significant pressure on the channels, especially on tall or exposed structures. Snow loads can accumulate and add weight to the structure, which the steel channels must be able to support. Seismic loads refer to the forces generated during an earthquake, and steel channels are designed to withstand these dynamic loads and prevent the structure from collapsing. In addition to these common loadings, steel channels can also withstand other specialized loadings, such as impact loads, vibration loads, and thermal loads. Impact loads can occur due to accidental collisions or sudden impact events and require steel channels to have high strength and toughness. Vibration loads can result from machinery or equipment operation and require steel channels to have good fatigue resistance. Thermal loads can cause expansion and contraction of the steel channels due to temperature changes, and they must be designed accordingly to prevent failure. Overall, steel channels have a high load-bearing capacity and can withstand a wide range of loadings, making them suitable for various structural applications in construction, engineering, and industrial sectors.

- Q:How do steel channels contribute to the overall ventilation of a building?

- Steel channels are an integral part of the overall ventilation system in a building as they provide pathways for the movement of air. These channels are strategically placed throughout the structure, allowing fresh air to enter and stale air to exit. By facilitating proper airflow, steel channels help regulate temperature, remove pollutants, and improve air quality, thereby contributing to a healthier and more comfortable environment inside the building.

- Q:What are the different methods for anchoring steel channels to a foundation?

- Different methods exist for anchoring steel channels to a foundation, depending on the specific requirements and load capacity of the structure. Some commonly used methods are as follows: 1. Anchor Bolts: This method involves drilling holes into the foundation and inserting anchor bolts, which are then secured using nuts and washers. This creates a strong connection between the channel and the foundation. 2. Chemical Anchoring: When drilling into the foundation is not feasible or preferred, chemical anchoring can be employed. This method utilizes epoxy resin or adhesive to bond the steel channel to the foundation. The adhesive is applied to the base of the channel and pressed onto the foundation surface. After curing, a strong bond is formed between the channel and the foundation. 3. Welding: Another method for anchoring steel channels involves welding the base of the channel directly to the foundation surface. This method provides a permanent and robust connection; however, it necessitates skilled welders and may not be suitable for all applications. 4. Expansion Anchors: When a temporary or removable connection is required, expansion anchors are utilized. These anchors consist of a bolt or screw inserted into a pre-drilled hole in the foundation. As the bolt is tightened, it expands and wedges itself against the hole's sides, creating a secure connection. 5. Concrete Embedment: In certain cases, steel channels can be directly embedded into the concrete foundation. This method involves pouring concrete around the channel, completely surrounding and encasing the steel. Once the concrete hardens, a solid and permanent connection is established. To select the appropriate anchoring method for steel channels, factors such as load capacity, environmental conditions, and project requirements should be taken into consideration. Consulting a structural engineer or construction professional is advised to ensure the proper selection and installation of the anchoring method.

- Q:Are steel channels suitable for use in piping systems?

- Steel channels are not suitable for use in piping systems. They are primarily intended for structural support or framing in construction projects and are not designed to withstand the pressure and flow of fluids in piping systems. Piping systems necessitate materials that are specially designed and tested to withstand high pressure, corrosion, and temperature fluctuations. Typical materials used in piping systems include steel pipes, copper pipes, and various types of plastic pipes that are specifically engineered for this purpose.

- Q:Are steel channels suitable for modular construction?

- Yes, steel channels are suitable for modular construction. They are commonly used in modular construction due to their strength, durability, and versatility. Steel channels provide structural support and can be easily assembled and connected to create modular units. Additionally, steel channels can withstand heavy loads and provide stability, making them an ideal choice for modular construction projects.

- Q:Are steel channels resistant to pests and insects?

- Yes, steel channels are generally resistant to pests and insects. Unlike wood, steel is not a food source for pests and insects, making it less appealing for them to infest. Steel channels are also less susceptible to damage caused by termites, carpenter ants, and other wood-boring insects that can significantly weaken wooden structures. Additionally, steel channels do not provide any hiding places or crevices for pests to nest or breed. Therefore, steel channels are considered a more durable and pest-resistant option compared to materials like wood.

- Q:How do steel channels compare to I-beams?

- Steel channels and I-beams are frequently utilized in construction and engineering for their structural properties. Despite some similarities, they possess distinct characteristics. One notable disparity lies in their shapes. Steel channels exhibit a C-shaped cross-section, featuring two flanges on either side and a connecting web. This design grants excellent structural support and resistance to bending. Conversely, I-beams possess an I-shaped cross-section, incorporating two flanges and a central web. This configuration evenly distributes the load across the top and bottom flanges, enabling it to efficiently bear heavy loads and resist bending and deflection. Another distinction is their weight-bearing capacity. I-beams are renowned for their exceptional strength-to-weight ratio, making them suitable for carrying substantial loads over extended spans. Steel channels, though still sturdy, are typically employed for lighter applications or as secondary structural components. Cost can also influence the comparison between steel channels and I-beams. Generally, steel channels are more cost-effective due to their simpler manufacturing process and smaller size. However, the specific cost will depend on the materials' size, length, and quality. Regarding versatility, both steel channels and I-beams offer a broad range of applications. Steel channels are commonly used in construction for framing, support structures, and bracing. They can also serve as lintels or purlins. On the other hand, I-beams find extensive usage in the construction of bridges, buildings, and large-scale infrastructure projects that require the handling of heavy loads and long spans. In conclusion, steel channels and I-beams possess varying shapes, weight-bearing capacities, costs, and applications. Steel channels are typically more cost-effective and suitable for lighter applications, while I-beams offer superior strength, making them ideal for heavy loads and longer spans. The choice between the two depends on the project's specific requirements and the desired balance between strength, cost, and design.

- Q:What are the different grades of steel channels?

- The different grades of steel channels include A36, A572, and A588.

- Q:How do steel channels contribute to the stability of roofing structures?

- Steel channels contribute to the stability of roofing structures by providing support and reinforcement. They are often used as purlins or joists to distribute the weight of the roof evenly, preventing sagging or collapse. The strength and durability of steel channels help withstand the forces of wind, snow, and other external factors, ensuring the overall stability and longevity of the roofing system.

- Q:Can steel channels be used for warehouse structures?

- Yes, steel channels can be used for warehouse structures. Steel channels provide strength, durability, and stability, making them suitable for supporting heavy loads and withstanding various weather conditions. They are commonly used in the construction of warehouse structures due to their versatility and ability to provide a rigid framework for the building.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled MS Mild Heavy Steel Rails for Mines

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords