Stainless Steel Coil SS 201/304/316/304L/316L/309S/310S/430 stainless steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Coil Description

The surface brightness and flatness of no2B is better than no2D. then through a special

surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses.

2.Main Features of the Stainless Steel Coil

• Tensile strength: not less than 520

• Provides that non-proportional extension strength: not less than 205

• Elongation: not less than 35; 3 density: 7.98

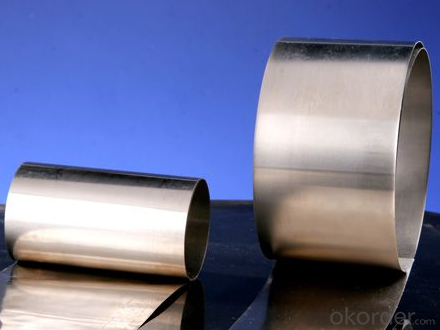

3. Stainless Steel Coil Images

4. Stainless Steel Coil Specification

| Grade: | 200series.300series. | Standard: | JIS,AISI,ASTM | Length: | as request |

| Thickness: | 0.3-3mm | Width: | 30-2000mm | Place of Origin: | Shanxi China (Mainland) |

| Brand Name: | CNBM | Model Number: | ss201/304/316/304L/316L/309S/310S/430 | Type: | Coil |

| Application: | hardware, foodstuff, manufacture, medic | Certification: | SGS | Item: | ss202/304/316/309s/310/410/420 stainless steel sheet |

| Packaging: | Export standard package or as your requirement | Delivery: | In 15 days | Stock: | Available |

5.FAQ of Stainless Steel Coil

①Who are you?

We are the manufacturer! We produce stainless steel products

with high quality & very competitive price!Please feel free to

contact us for more information!

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How about your company?

A world class manufacturer & supplier of castings forging in Stainless Steel Sheet,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q:How are steel strip coils formed and wound?

- The manufacturing process for steel strip coils involves several steps that result in the formation and winding of the coils. To begin, a large steel coil is unrolled and flattened to create a continuous steel strip. This strip is then shaped into the desired width and thickness by passing it through a series of rollers and forming devices. After the strip has been formed, it is wound into a coil using a winding machine. The machine feeds the strip onto a rotating mandrel, which gradually increases in diameter as the coil takes shape. To ensure a tight and compact coil, tension is applied during the winding process. During the winding process, it is crucial to evenly wind the strip to prevent any deformation or damage to the coil. This is achieved by controlling the tension, speed, and alignment of the strip as it is fed onto the mandrel. Once the desired length of steel strip has been wound into a coil, the winding machine cuts the strip and secures the loose end to prevent unraveling. The completed steel strip coil is then ready for further processing or transportation. In conclusion, the precision and careful control of various parameters are necessary to produce high-quality steel strip coils that meet the required specifications.

- Q:Are steel strips used in the production of kitchen utensils?

- Yes, steel strips are commonly used in the production of kitchen utensils due to their durability and corrosion resistance.

- Q:Can steel strips be used in aerospace applications?

- Yes, steel strips can be used in aerospace applications.

- Q:Are steel strips commonly used in the manufacturing of packaging materials?

- Yes, steel strips are commonly used in the manufacturing of packaging materials, especially for heavy-duty packaging and securing goods during transportation. They provide strength and durability to the packaging, ensuring the safe handling and delivery of goods.

- Q:Can steel strips be used in the production of aircraft components?

- Yes, steel strips can be used in the production of aircraft components. Steel is a strong and durable material that has been widely used in the aerospace industry for various applications. Steel strips can be used to make structural components such as brackets, frames, or reinforcements, as well as for manufacturing parts like hinges or fasteners. The specific type of steel and its properties, such as strength, corrosion resistance, and weight, will determine its suitability for different aircraft components. It is important to ensure that the steel strips used meet the required specifications and standards for aviation safety and performance.

- Q:How are steel strips heat-treated for improved properties?

- Steel strips are heat-treated by subjecting them to specific temperatures and cooling rates to alter their microstructure and improve their properties. This process involves heating the steel strips to a high temperature, typically above the critical point, and then rapidly cooling them, often using water or oil quenching. This rapid cooling, known as quenching, helps to harden the steel by transforming its microstructure into a harder and more brittle state. After quenching, the strips are usually tempered by reheating to a lower temperature to relieve internal stresses and improve toughness. This heat treatment process allows for the manipulation of the steel's properties such as hardness, strength, and ductility, making it suitable for various applications.

- Q:How are steel strips used in the production of metal shelving?

- Steel strips are commonly used in the production of metal shelving as they provide strength and stability to the structure. These strips are often used as the main framework or support system for the shelves, ensuring that they can bear the weight of the items placed on them. The steel strips are typically cut and shaped according to the desired dimensions and then welded or bolted together to form the frame of the shelving unit. They are also used to create the horizontal and vertical supports for the shelves, keeping them securely in place. Additionally, steel strips can be used to reinforce the corners and joints of the shelving unit, enhancing its overall durability and longevity. Overall, steel strips play a vital role in the production of metal shelving by providing the necessary strength and structural integrity required for heavy-duty storage solutions.

- Q:How are steel strips used in the production of metal doors and windows?

- Steel strips are an essential component in the production of metal doors and windows. These strips, which are typically made of high-quality steel, are used in various stages of the manufacturing process to ensure the strength, durability, and aesthetic appeal of the final product. One of the primary uses of steel strips is in the fabrication of door and window frames. These frames provide the structural support and stability required for the installation and operation of doors and windows. Steel strips are cut, bent, and welded together to create the desired frame shape and size. The strength and rigidity of steel ensure that the frames can withstand the weight of the door or window and any external forces. Steel strips also play a crucial role in enhancing the security features of metal doors and windows. They are often used to reinforce the frames and add additional strength to prevent forced entry. By incorporating steel strips within the frame structure or applying them as reinforcements, metal doors and windows become more resistant to break-ins, making them an ideal choice for commercial and residential properties. Furthermore, steel strips are used to create decorative elements on metal doors and windows. They can be formed into various shapes, patterns, or designs to enhance the aesthetic appeal of the product. These decorative steel strips can be customized to match the architectural style or personal preferences of the customers, adding a touch of elegance and sophistication to the overall appearance of the doors and windows. In summary, steel strips are integral to the production of metal doors and windows. They are used in the fabrication of frames, reinforcing the structures for increased strength and security. Additionally, steel strips can be utilized as decorative elements, providing a visually appealing finish to the final product. With their versatility and durability, steel strips ensure that metal doors and windows meet the highest standards in terms of functionality, safety, and aesthetics.

- Q:How are steel strips used in the production of oil and gas pipelines?

- Steel strips are used in the production of oil and gas pipelines as they serve as the main material for manufacturing the pipes. These strips are typically formed and welded into cylindrical shapes to create the pipelines that transport oil and gas over long distances. The steel's strength, durability, and resistance to corrosion make it an ideal choice for ensuring the safety and efficiency of oil and gas transportation.

- Q:How are steel strips used in the production of electronics?

- The production of electronics relies on the utilization of steel strips in various manners. One prevalent application involves their use in the manufacturing process of printed circuit boards (PCBs). These PCBs are essential elements within electronic devices as they serve as platforms for the mounting and interconnecting of diverse electronic components. By serving as a base material, steel strips offer stability and support to the PCBs. Additionally, electronic enclosures also employ steel strips during production. These enclosures act as protective housing for the internal components of electronic devices, shielding them from external factors including dust, moisture, and physical harm. Steel strips are frequently employed in constructing the frames or outer shells of these enclosures, guaranteeing both strength and durability. Moreover, connectors and terminals, vital for establishing connections between different parts of electronic devices such as cables, wires, and circuit boards, rely on steel strips during production. By utilizing steel strips, manufacturers are able to create reliable and robust connections, ensuring the efficient transmission of electrical signals. In conclusion, steel strips assume a pivotal role in the production of electronics by acting as a base material for PCBs, providing structural support to electronic enclosures, and enabling the creation of connectors and terminals. Their durability, strength, and conductivity make them an indispensable component within the manufacturing process of electronic devices.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil SS 201/304/316/304L/316L/309S/310S/430 stainless steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords