Single Phase1K Inverter made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Single Phase1K Inverter

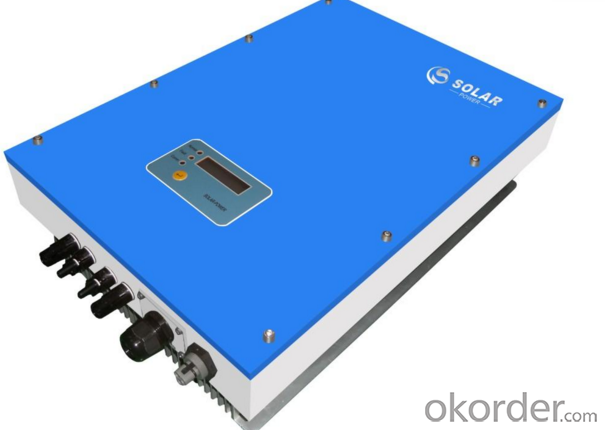

Single Phase1K Inverter made in China

Features of Single Phase1K Inverter

High MPPT accuracy(>99.9%)

Wide DC input range (60~300 Vdc), compatible with different module

Easy to wire, install and operate

IP65 design, suitable for indoor and outdoor installation

10 years warranty(5~25 years optional)

Technical Data of Single Phase1K Inverter

| Type | Omniksol-1k-TL-M |

| Input(DC) | |

| Max.PV Power | 1.25kW |

| Max,DC Voltage | 400V |

| Operating MPPT Voltage Range | 60-300V |

| MPPT Voltage Range at Nominal Power | 100-300V |

| Start up DC Voltage | 70V |

| Turn off DC Voltage | 50V |

| Max, DC Current | 10A |

| Max, Short Cicuit Current for each MPPT | 12A |

| Number of MPP trackers | 1 |

| Number of DC Connection for each MPPT | 1 |

| DC Connection Type | MC4 connector |

| Output(AC) | |

| Max,AC Apparent Power | 1000VA |

| Nominal AC Power (cos phi = 1) | 1000W |

| Nominal Grid Voltage | 220V/230V/240V |

| Nominal Grid Frequency | 50Hz/60Hz |

| Max, AC Current | 5.0A |

| Grid Voltage Range** | 185-276V |

| Grid Frequency Range** | 45-55Hz/55-65Hz |

| Power Factor | >0.99 |

| Total Harmonic Distortion(THD) | <3% |

| Feed in Starting Power | 30W |

| Night time Power Consumption | <1W |

| Standby Consumption | 6W |

| AC Connection Type | Plug-in connertor |

| Efficiency | |

| Max,Efficiency | 95.5% |

| Euro Efficiency | 94.2% |

| MPPT Efficiency | 99.9% |

| Safety and Protection | |

| DC Insulation Monitoring | Yes |

| DC Switch | Optional |

| Residual Current Monitoring Unit (RCMU) | Integrated |

| Grid Monitoring with Anti-islanding | Yes |

| Protection Class | Ⅰ(According to IEC 62103) |

| Overvoltage Category | PV Ⅱ/ Mains Ⅲ(According to IEC 62109-1) |

| Reference Standard | |

| Safety Standard | EN 62109, AS/NZS 3100 |

| EMC Standard | EN 6100-6-1, EN 6100-6-2, EN 6100-6-3 EN 6100-6-4, EN 6100-3-2, EN 6100-3-3 |

| Grid Standard | VDE-AR-N4105. VDE-0126-1-1,G83/1,EN 50438,RD1699,CEI 0-21, AS4777,C10/C11 |

| Physical Structure | |

| Dimensions | 210x297x90mm |

| Weight | 5.5kg |

| Environmental Protection Rating | IP 65 (According to IEC 60529) |

| Cooling Concept | Natural convection |

| Mounting Information | Wall bracket |

| General Data | |

| Operating Temperature Range | -25℃ to +60℃(derating above 45℃) |

| Relative Humidity | 0% to 98%, no condensation |

| Max. Altitude (above sea level) | 2000m |

| Noise Type | <45dB |

| Isolation Type | Transformerless |

| Display | 2LED Backlight 16*2 Character LCD |

| Data Communication | RS485(WiFi, GRPS optional) |

| Computer Communication | RS232 as option |

| Standard Warranty | 10 Years (5-25 years optional) |

IMages of Single Phase1K Inverter

FAQ

Q: Do you have the CE, TUV, UL Certification?

A: We’ve already passed all the tests, and any certificate is available.

Q: Have you ever sold your products to companies in my country?

A: Of course, we have customers in all general PV markets, but I think we should expand our market share along with the market growth.

Q: When did your company set up? You are a new company, how can I believe your quality?

A: We entered into Solar PV industry in 2005, now we have several plants in manufacturing of a-Si and c-Si panels, and our capacity is 220MW per year. Till now we have already passed all the tests by authorized laboratories, e.g. TUV, CE, UL.

Q: Can you help us install the module if we cooperate with you?

A: We haven’t entered into installation sector, but we have the plan in near future.

Q: How do you pack your products?

A: We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

Q: Can you do OEM for us?

A: Yes, we can.

Q: Can we visit your factory?

A: Surely, I will arrange the trip basing on your business schedule.

- Q:Can a solar inverter be used with different types of tracking algorithms?

- Yes, a solar inverter can be used with different types of tracking algorithms. The inverter is designed to convert the DC power generated by solar panels into usable AC power for various applications. The tracking algorithm, on the other hand, is responsible for optimizing the solar panel's orientation to maximize energy production. Different tracking algorithms like fixed tilt, single-axis, or dual-axis can be employed with the solar inverter to enhance energy harvesting based on factors such as sun's position, time of day, and weather conditions.

- Q:Can a solar inverter be used in areas with high temperature fluctuations?

- Yes, a solar inverter can generally be used in areas with high temperature fluctuations. Solar inverters are designed to operate in a wide range of temperature conditions, typically between -20°C to 50°C (-4°F to 122°F), depending on the specific model. They are built with temperature protection mechanisms to ensure their functionality and durability even in extreme temperature variations. However, it is important to note that prolonged exposure to extreme temperatures at the upper or lower limits of their operating range can affect the performance and lifespan of the inverter. Therefore, proper installation and regular maintenance are crucial to ensure optimal performance in areas with high temperature fluctuations.

- Q:What is the role of a remote monitoring system in a solar inverter?

- The role of a remote monitoring system in a solar inverter is to allow for real-time monitoring and management of the solar power generation and inverter performance from a remote location. It provides valuable insights into the system's efficiency, troubleshooting capabilities, and helps ensure optimal performance and timely maintenance. Additionally, a remote monitoring system allows for data analysis, performance tracking, and can facilitate predictive maintenance to maximize the overall efficiency and longevity of the solar inverter system.

- Q:How does a solar inverter ensure safety during maintenance?

- A solar inverter ensures safety during maintenance by automatically disconnecting the system from the grid and de-energizing the circuits. This prevents any potential electrical shocks or accidents while the maintenance personnel work on the system.

- Q:Can a solar inverter work in low light conditions?

- Yes, a solar inverter can work in low light conditions. While the output power of a solar inverter may decrease in low light conditions, it is still capable of converting the available sunlight into usable electricity. The performance may vary depending on the specific model and technology used, but modern solar inverters are designed to work efficiently even in low light situations.

- Q:How does a solar inverter handle grid islanding conditions?

- A solar inverter detects grid islanding conditions by monitoring the voltage and frequency of the grid. When it detects a deviation from the normal range, indicating an islanding event, it immediately stops supplying power to the grid. This is done to ensure the safety of utility workers who may be repairing the grid.

- Q:Can a solar inverter be used in commercial applications?

- Yes, a solar inverter can be used in commercial applications. In fact, solar inverters are commonly used in commercial settings to convert the direct current (DC) produced by solar panels into alternating current (AC) that can be used to power various electrical devices and appliances. Commercial buildings often have larger solar systems installed, requiring more powerful inverters to efficiently convert the solar energy into usable electricity for the facility's commercial operations.

- Q:Are there any safety risks associated with solar inverters?

- Yes, there can be safety risks associated with solar inverters. While solar inverters are generally considered safe, there are a few potential hazards to be aware of. These include electrical shock, fire hazards, and the release of toxic gases. It is important to ensure proper installation, regular maintenance, and adherence to safety guidelines to mitigate these risks.

- Q:What is the role of MPPT (Maximum Power Point Tracking) in a solar inverter?

- The role of MPPT (Maximum Power Point Tracking) in a solar inverter is to optimize the efficiency of the solar panel system by continuously adjusting the voltage and current to ensure that the panel operates at its maximum power point. This helps to extract the maximum available power from the solar panels under varying environmental conditions, such as changes in sunlight intensity or temperature. By dynamically tracking the optimal operating point, MPPT maximizes the energy output of the solar panels and improves the overall performance of the solar inverter system.

- Q:Can a solar inverter be used in regions with high altitude conditions?

- Yes, a solar inverter can be used in regions with high altitude conditions. However, it is important to consider the specific requirements and limitations of the particular solar inverter model being used. High altitude conditions may affect the performance and efficiency of the inverter, as factors like lower air density and temperature can impact its cooling capacity. Therefore, it is crucial to select a solar inverter that is specifically designed and tested for high altitude operations to ensure optimal performance and reliability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Single Phase1K Inverter made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords